Liquid crystal alignment agent, liquid crystal alignment film, liquid crystal alignment film forming method, liquid crystal display element

A liquid crystal alignment agent, liquid crystal alignment technology, applied in the direction of liquid crystal materials, chemical instruments and methods, instruments, etc., can solve the problems of large cumulative exposure, insufficient sensitivity, etc., achieve high radiation sensitivity, reduce production costs, electrical Excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0148] Hereinafter, the present invention will be described more specifically by way of examples, but the present invention is not limited by these examples.

[0149]

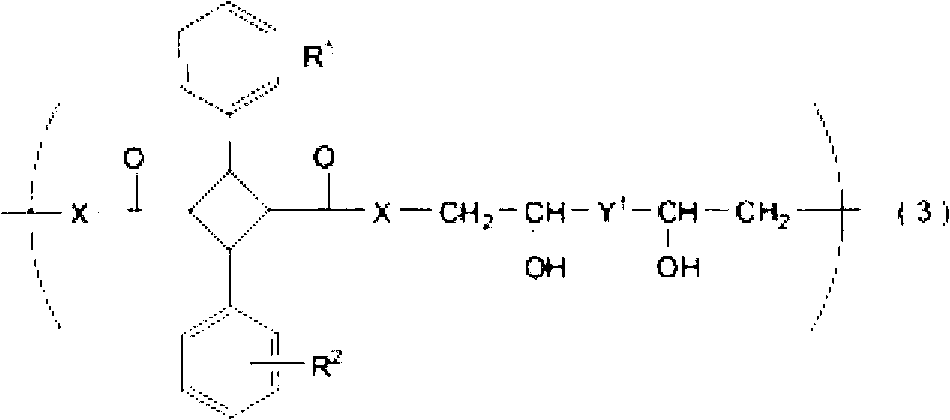

[0150] A compound represented by the following formula (B-1) was synthesized according to the following scheme.

[0151] [chemical 6]

[0152]

Synthetic example 1

[0154] Add 2.00 g of (E)-cinnamic acid to 10 mL of a water / ethanol=1 / 1 solution, and heat to 90° C. in an oil bath to completely dissolve it. The setting of the oil bath was set at 50° C., crystallization was gradually advanced, and 1.3 g (yield: 65%) of α-crystals of (E)-cinnamic acid were obtained. 150 mg of the α-crystals obtained by recrystallization were pulverized in a mortar until they became powdery, and were sandwiched between two Pyrex (registered trademark) glass plates to obtain uniform thickness. Light irradiation was performed for 4 hours using a 500 W high-pressure mercury lamp to obtain 147 mg of the compound (B-1) represented by the above formula (B-1). In addition, by repeating the synthesis at the above-mentioned scale, the necessary amount in the synthesis examples of the polyesters to be described later can be ensured.

[0155]

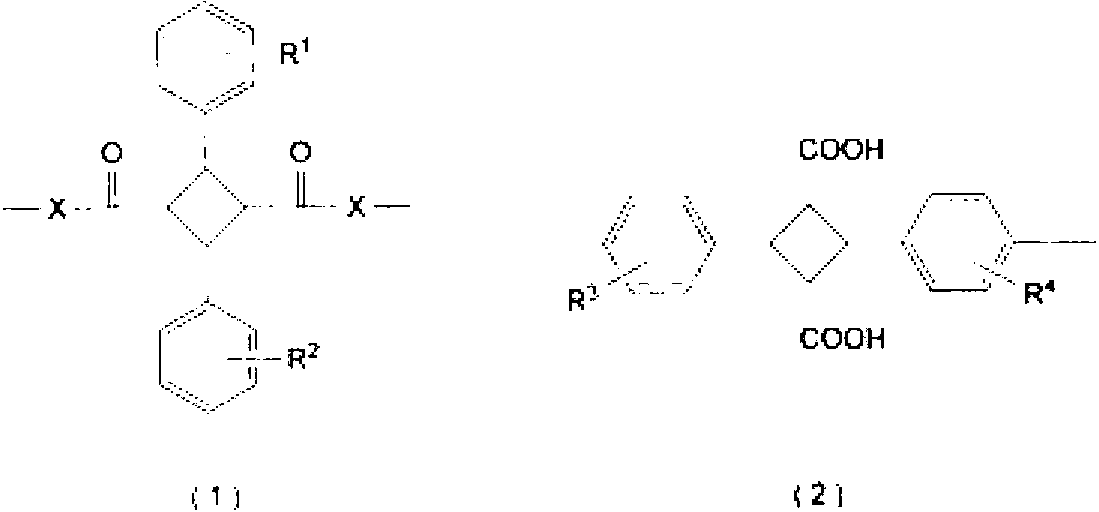

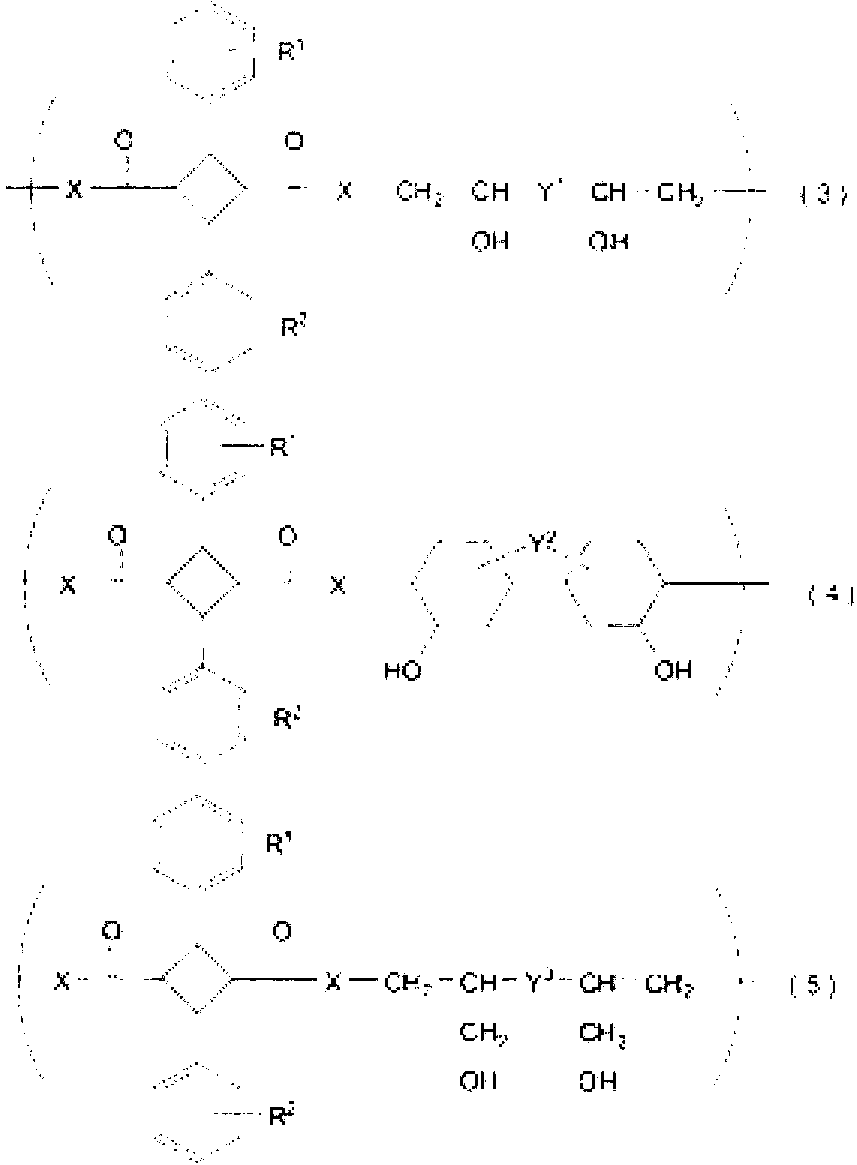

[0156] Diepoxide compounds used in the synthesis of polyester are shown below.

[0157] [chemical 7]

[0158]

example 1

[0160] 0.1 mol (29.62g) of the compound (B-1) and 0.1 mol (17.72g) of the diepoxy compound (E-1) represented by the above formula (E-1) were dissolved in N-methyl-2-pyrrolidone 110.46 g, reacted at 140° C. for 9 hours. Next, the reaction mixture was mixed with a large excess of methanol to precipitate the reaction product. Then, it wash|cleaned with methanol, it dried at 40 degreeC under reduced pressure for 15 hours, and obtained 45.9 g of polyester (A-1) (yield rate: 97.0%).

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com