An aluminum alloy triangular valve

A triangular valve, aluminum alloy technology, applied in the direction of sliding valves, valve details, valve devices, etc., can solve the problems of embroidered layer blocking water flow, easy to be corroded, etc., and achieve the effect of light weight, good mechanical properties, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with preferred embodiment further illustrate technical solution of the present invention:

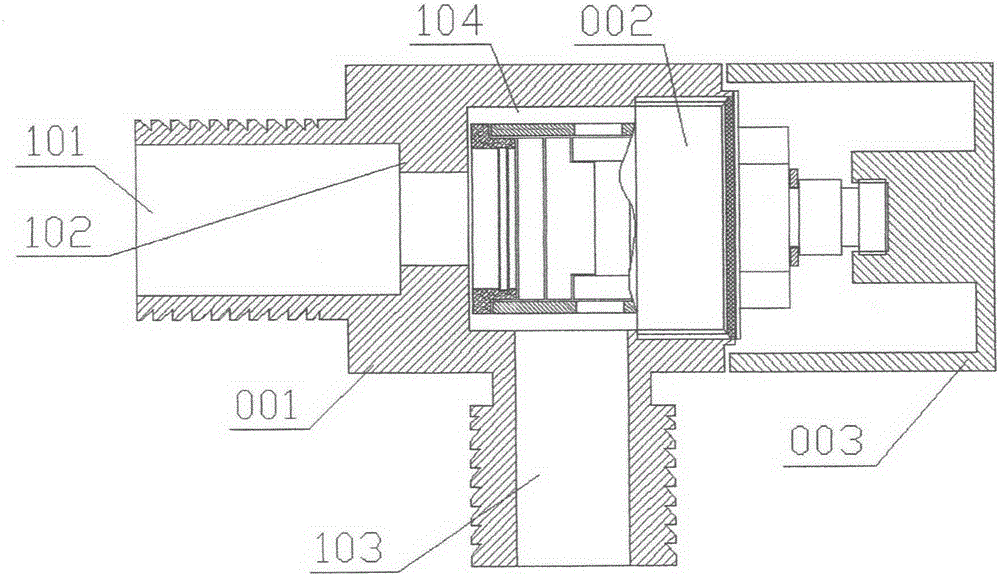

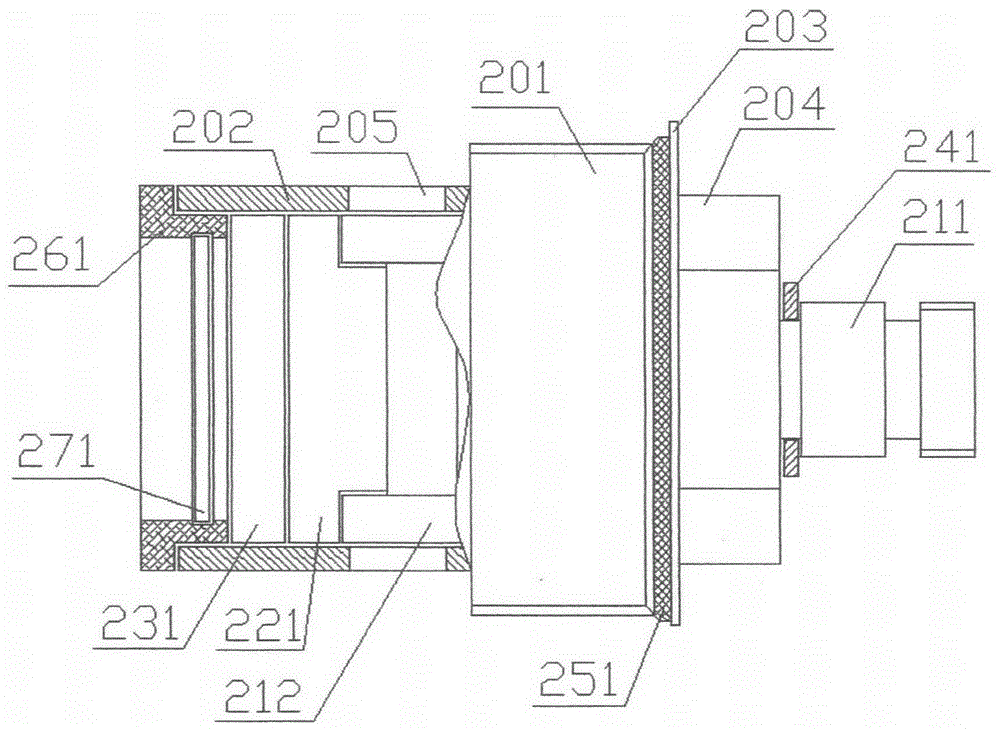

[0020] Such as figure 1 , figure 2 As shown, the aluminum alloy triangular valve of the present invention includes a valve sleeve 001, a valve core 002 and a rotary handle 003. The valve sleeve 001 is provided with a valve core cavity 104, a water inlet 101 and a water outlet 103. The water inlet 101 is provided with an inwardly protruding circular ring 102 with a reduced aperture, which is in close contact with the valve core 002 . The valve core 002 includes a valve core sleeve, a rotating assembly, a static valve chip 231 , a moving valve chip 221 and a soft rubber ring 261 . The valve core sleeve includes a valve sleeve connecting portion 201 and a valve core sleeve portion 202 . The valve sleeve connecting portion 201 is threadedly connected with the valve sleeve 001 and is provided with a valve sleeve sealing ring 251 . Half of the soft rubber ring...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| Poisson's ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com