Method for constructing performance evaluation device for reflow soldering equipment

A technology for reflow soldering and evaluating devices, which is applied in the direction of thermometers and measuring devices using electrical devices, electrical/magnetic components directly sensitive to heat, etc., can solve problems such as non-uniformity, achieve a small thermal expansion coefficient, avoid heat exchange, Good anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below, in conjunction with accompanying drawing and specific embodiment, the invention is further described:

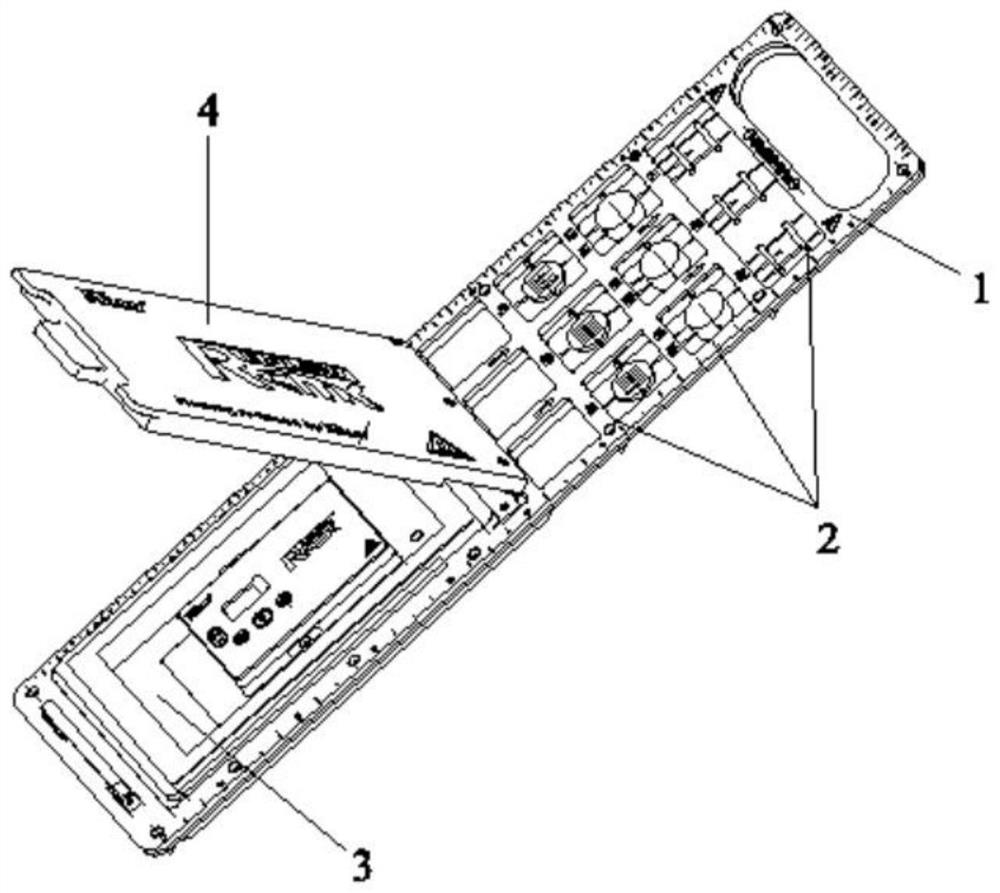

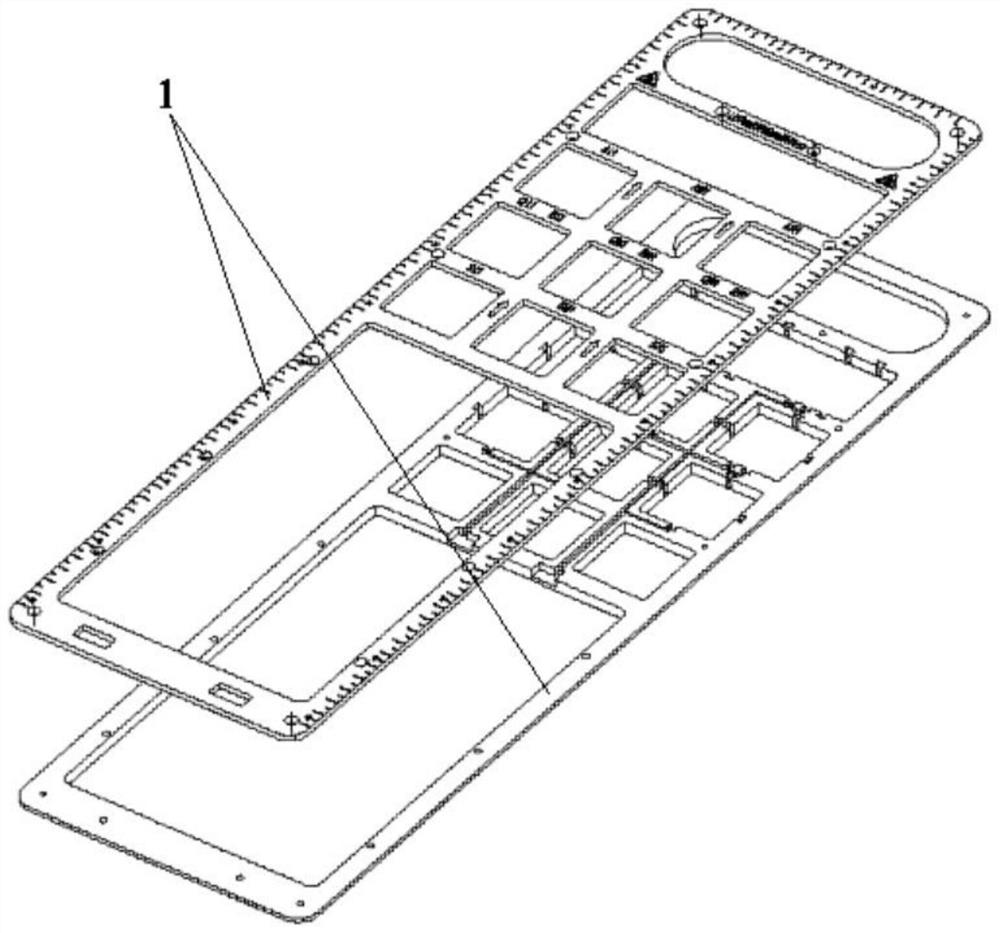

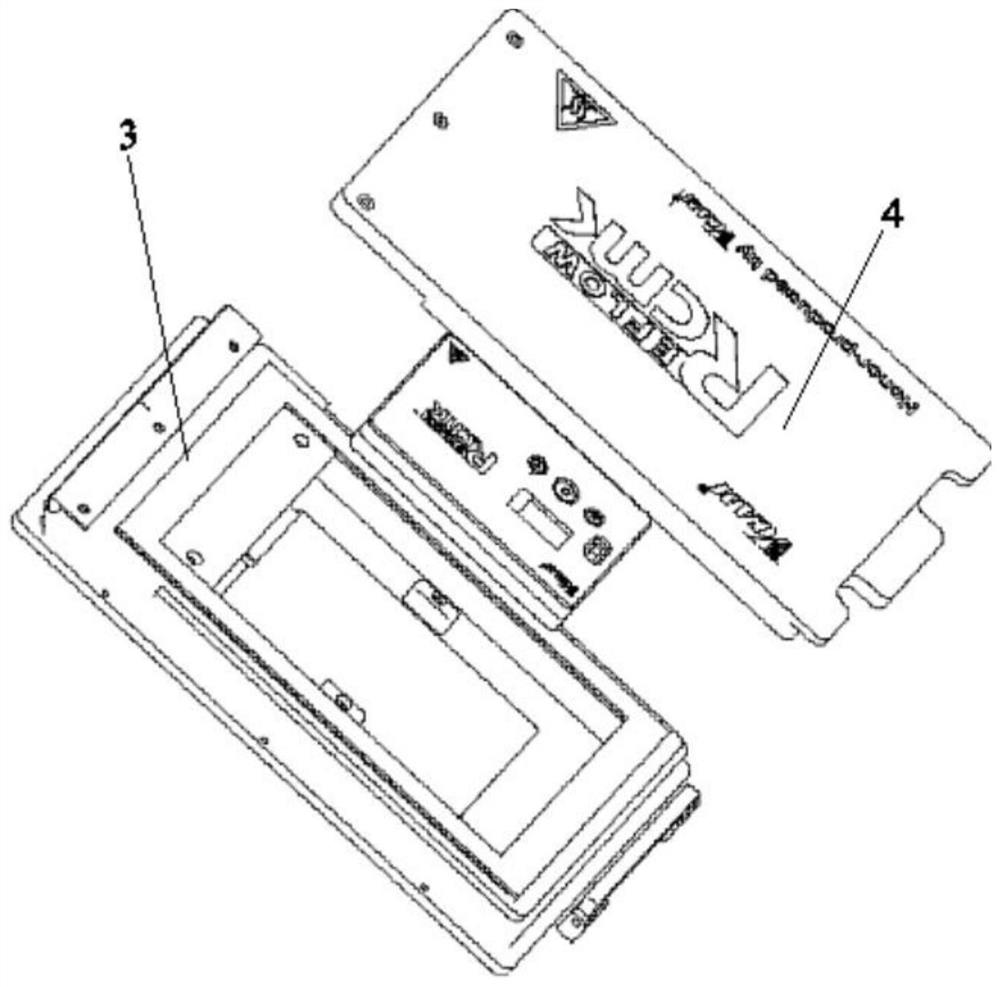

[0032] see Figure 1-3 , according to the embodiment of the present invention, the method for building a performance evaluation device for reflow soldering equipment includes building a support frame 1 , a heat capacity module 2 , a thermal insulation device 3 and a data collector 4 .

[0033] Support frame 1: The support frame 1 is made of high temperature resistant synthetic stone or high temperature resistant fiber mixed plate or high temperature resistant carbon fiber plate material. The support frame 1 includes a cover layer and a bottom layer. The cover layer is used for heat insulation and marking various sizes The function of the name can identify the scale value and size of the length and width of the vehicle, as well as the name of the deployed heat capacity module 2. The bottom layer is used for heat insulation and deployment of corresponding thermocou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com