Electromagnetic induction heating warm air blower

An electromagnetic induction heating and induction heating technology, applied in air heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of short service life of resistance heating wire, harsh use environment, frequent maintenance and other problems, and achieve preheating. The effect of short time, high manufacturing cost and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

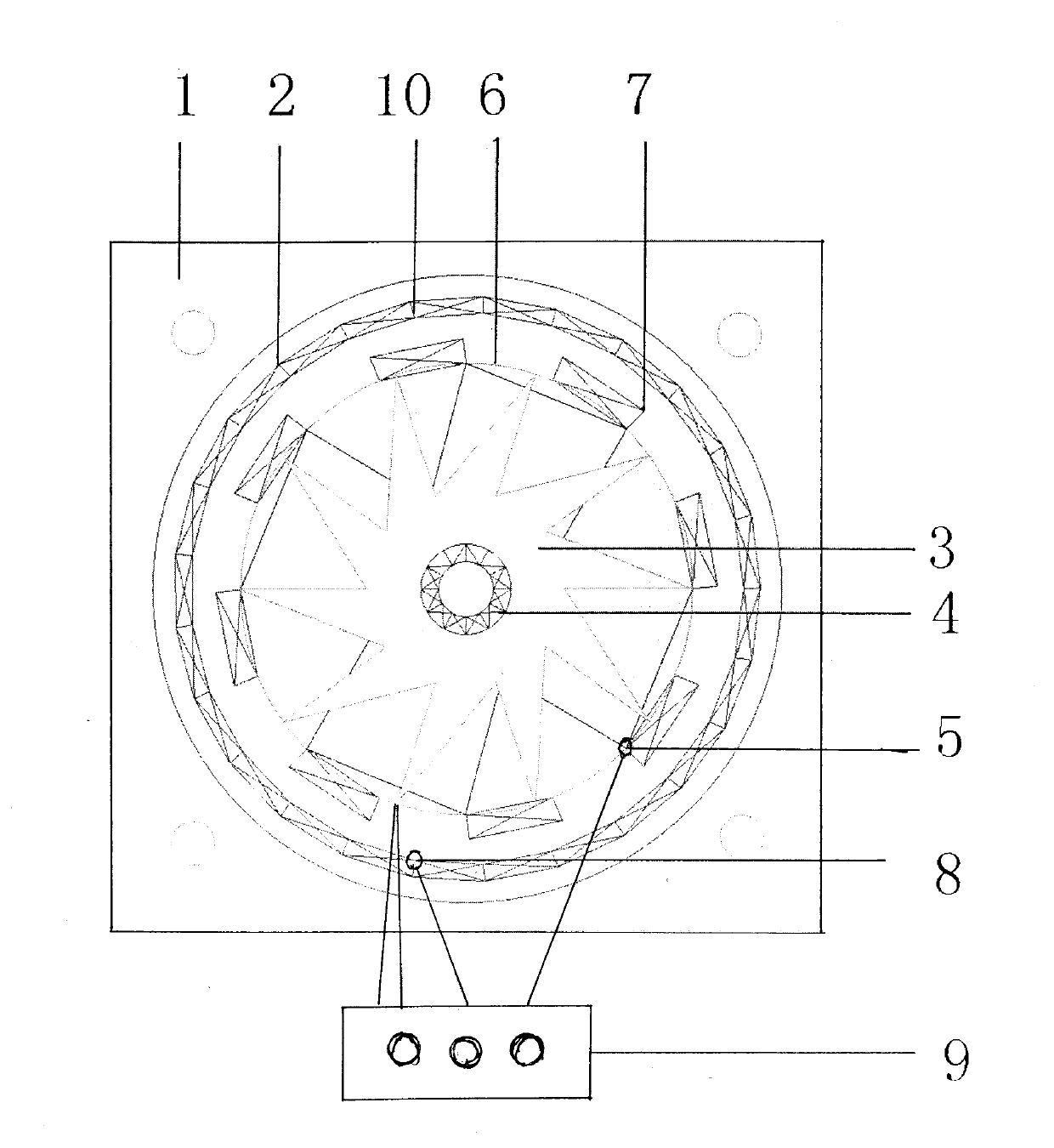

[0016] In the figure, the electromagnetic induction heating technology is used as the heat source of the heater, and the induction heating rod (4) directly generates heat through the electric energy of the induction coil (6) and transfers the heat energy to the radiator (3), and the radiator (3) is integrated Sunflower Radiator. The inner layer of the radiator (3) is in close contact with the outer layer of the induction heating rod (4), thereby transferring heat energy from the induction heating rod (4) to the radiator (3). The electromagnetic induction coil (6) is wound on the outer layer of the radiator (3), and the radiator (3) is the radiator of the induction heating rod (4), the radiator of the electromagnetic induction coil (6), and the electromagnetic induction coil ( 6) The coil skeleton. The structural compactness of the heater is increased, and the volume and manufacturing cost of the heater are reduced.

[0017] In order to increase the heat transfer speed and ef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com