Foundation coefficient K30 test method of railroad bed for fine-grained soil construction

A technology of foundation coefficient and railway roadbed, which is applied in the direction of mechanical devices, measuring devices, instruments, etc., can solve the problems of complicated operation in the test process, long waiting time for shutdown, and affecting the progress of the project, so as to achieve high test efficiency and reduce shutdown waiting Time, the effect of speeding up the progress of the project

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

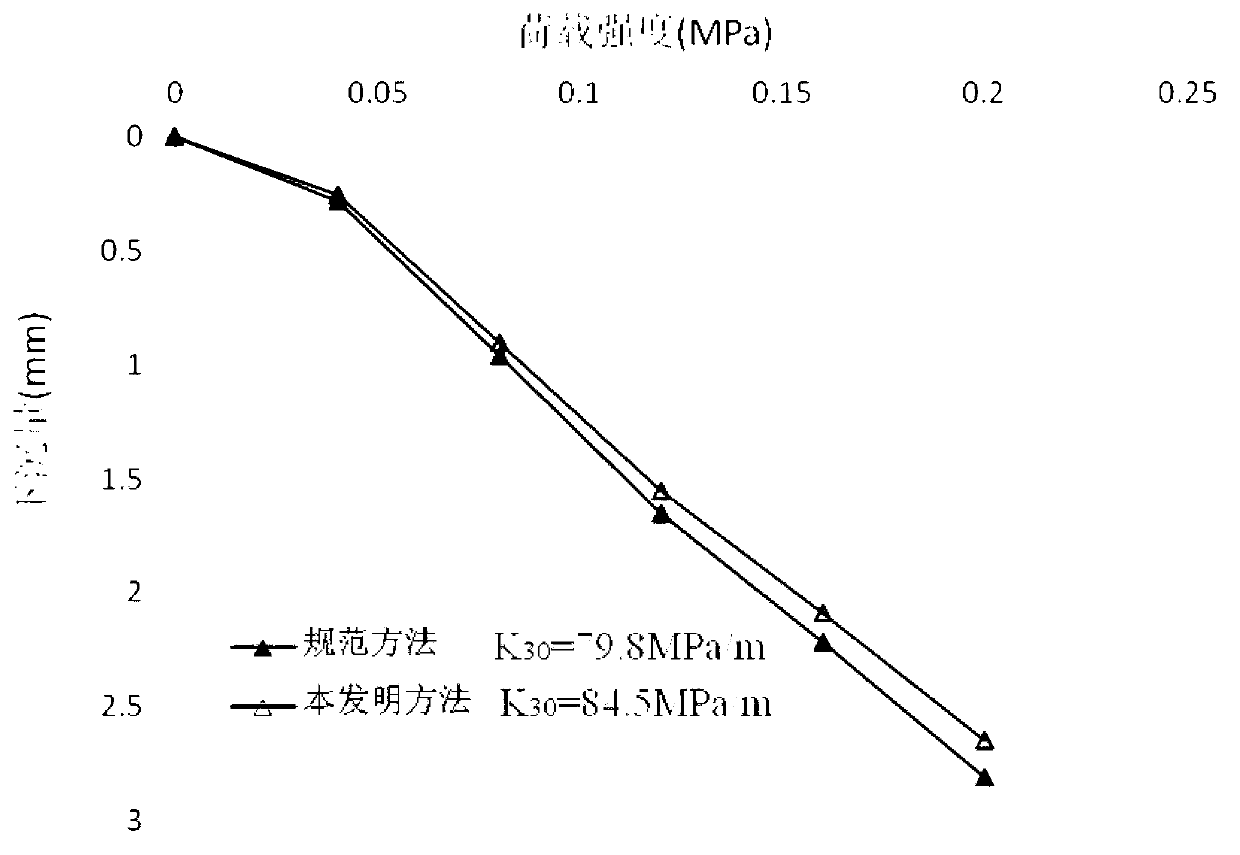

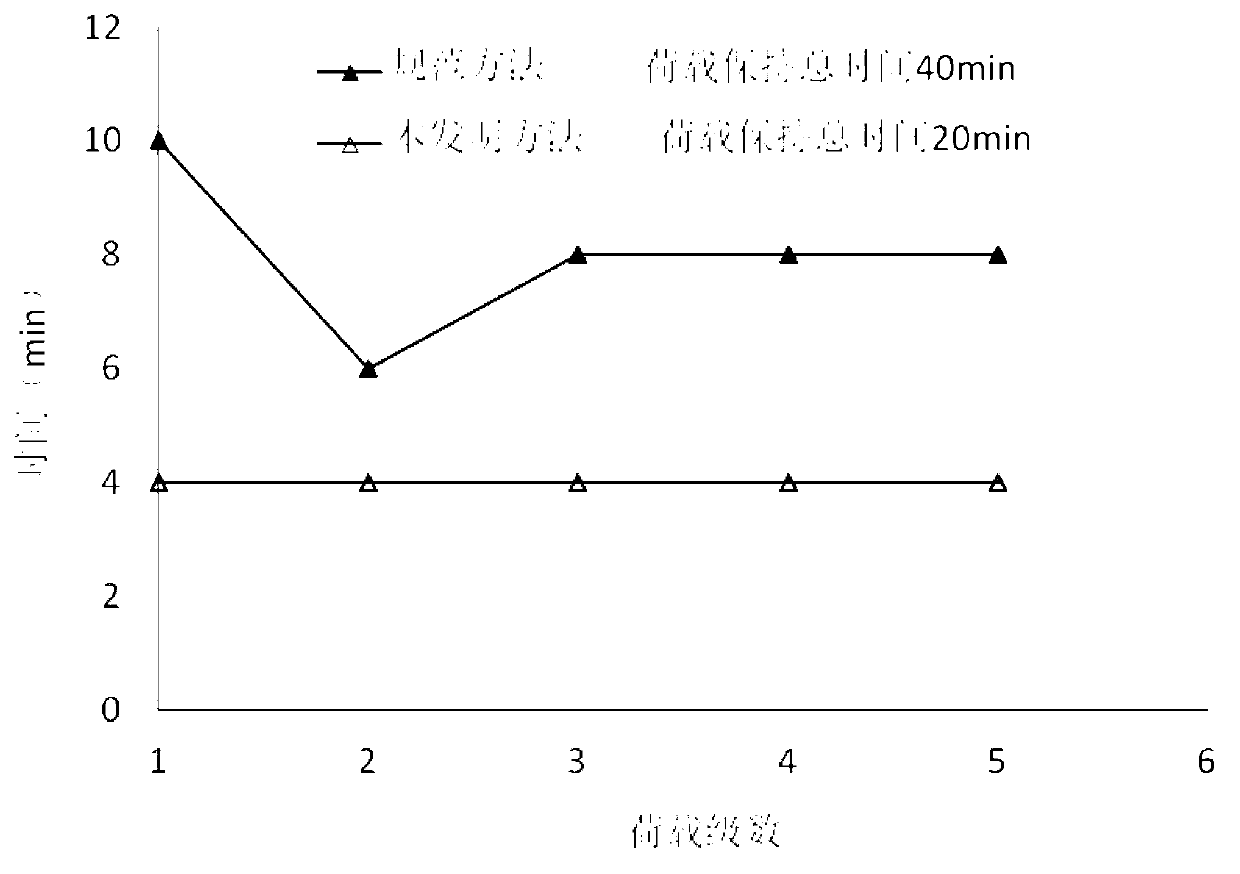

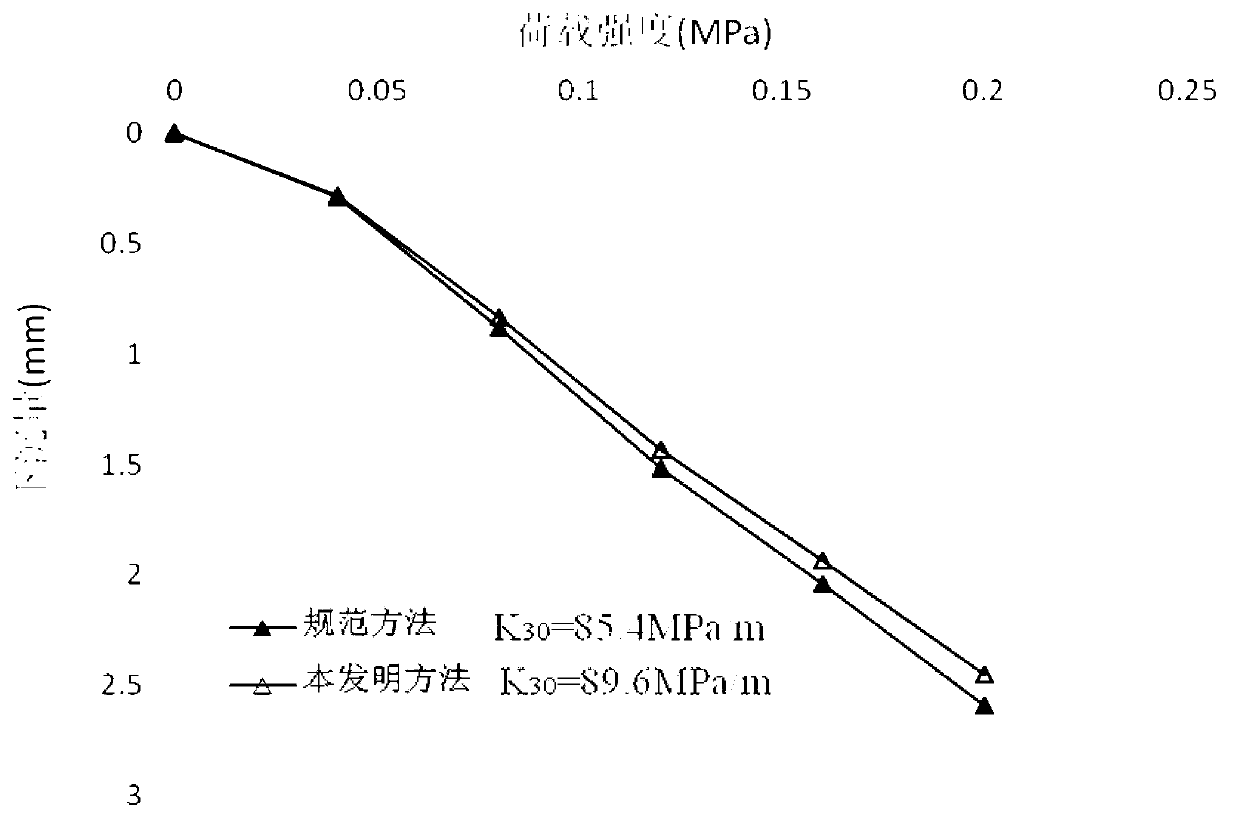

[0019] A specific embodiment of the present invention is, a kind of subgrade coefficient K of the railway embankment that is used for fine-grained soil construction 30 The test method includes the steps of leveling the test surface on the site, installing the foundation coefficient tester, preloading and step-by-step loading in the loading test, and the load during preloading is 0.04MPa. The specific method of step-by-step loading in the described loading test is: the load of the first stage loading is 0.04MPa, and then the increment of each stage load is 0.04MPa step-by-step loading (as the total load of the second stage loading is 0.08 MPa, the total load of the third level of loading is 0.12MPa), the load holding time after each level of loading is 4 minutes, and when the load holding time of each level of loading meets the requirements, record the subsidence of this level of loading until Reach the foundation coefficient K 30 When the test termination condition of the tes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com