Data collection analysis system based on Mitsubishi MELPLAC 2000

A technology for data collection and analysis and data analysis, applied in the field of data processing, can solve the problems of fewer sampling points, fewer equipment operation data collection points, and fewer operation data collection points, etc. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

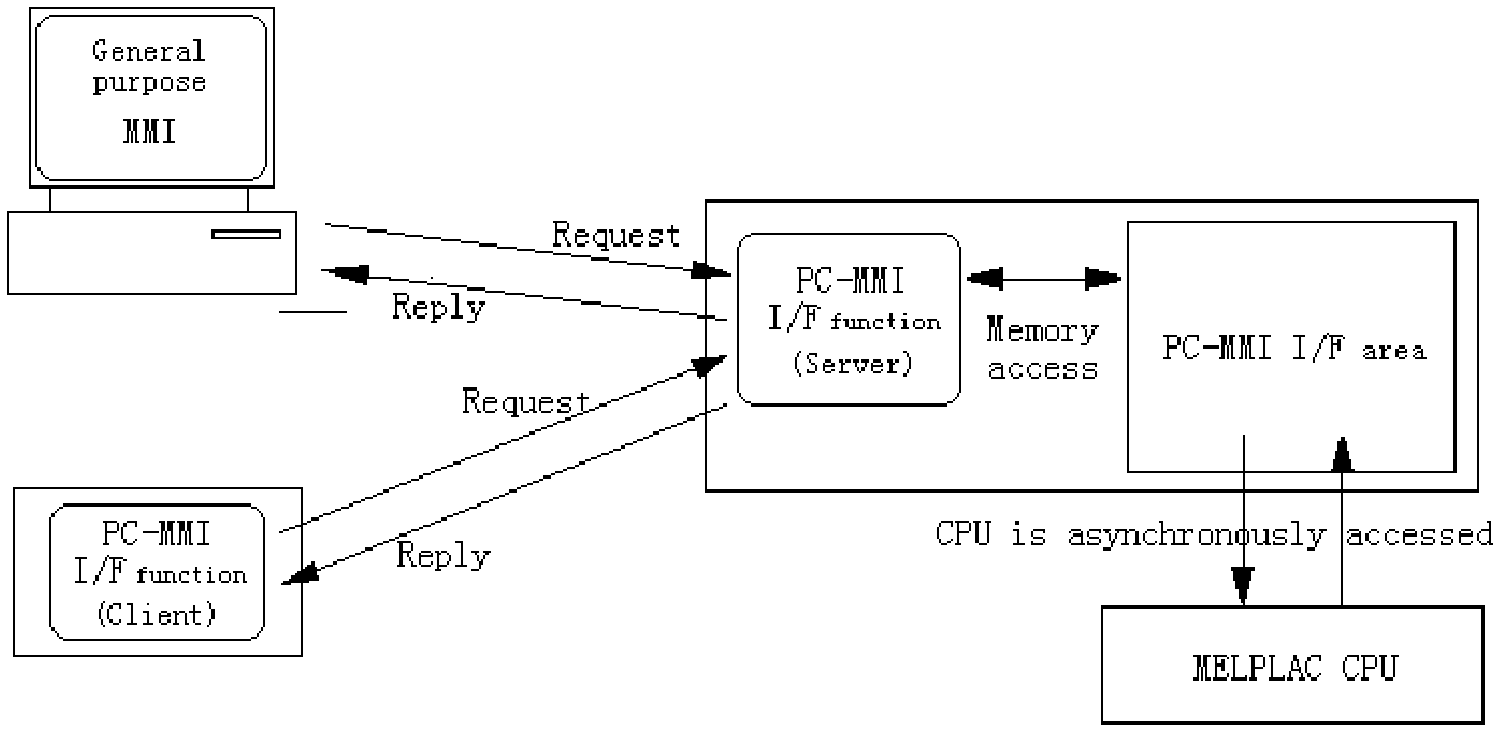

[0047] figure 1 Among them, the control system of the original MELPLAC 2000 industrial computer is equipped with a man-machine interface in a Client / Server structure to ensure that additional man-machine interface nodes can be connected while the system is running normally.

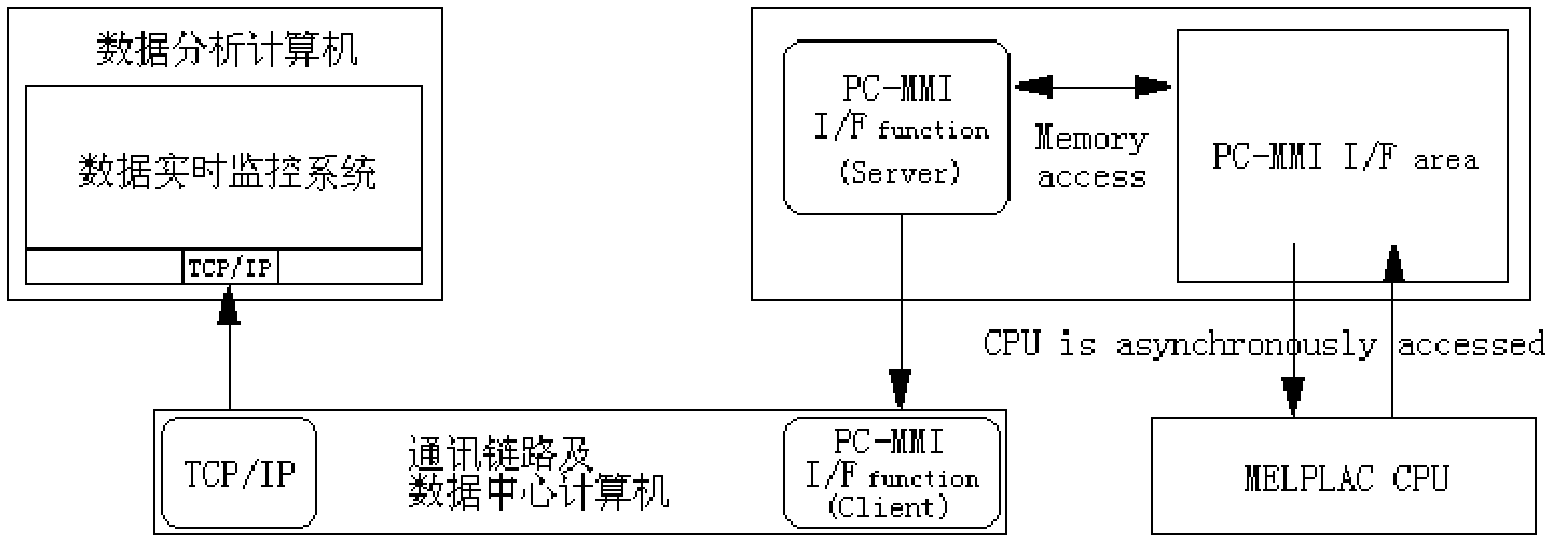

[0048] figure 2 Among them, the technical solution of the present invention utilizes the original man-machine interface of the MELPLAC 2000 industrial computer to construct a new data channel link for establishing a data collection and analysis system.

[0049] Since the above two diagrams both adopt legends and labeling methods commonly used in the industry, those skilled in the art can fully understand their hardware configuration and information flow direction, so their specific link relationship and signal flow direction will not be described here.

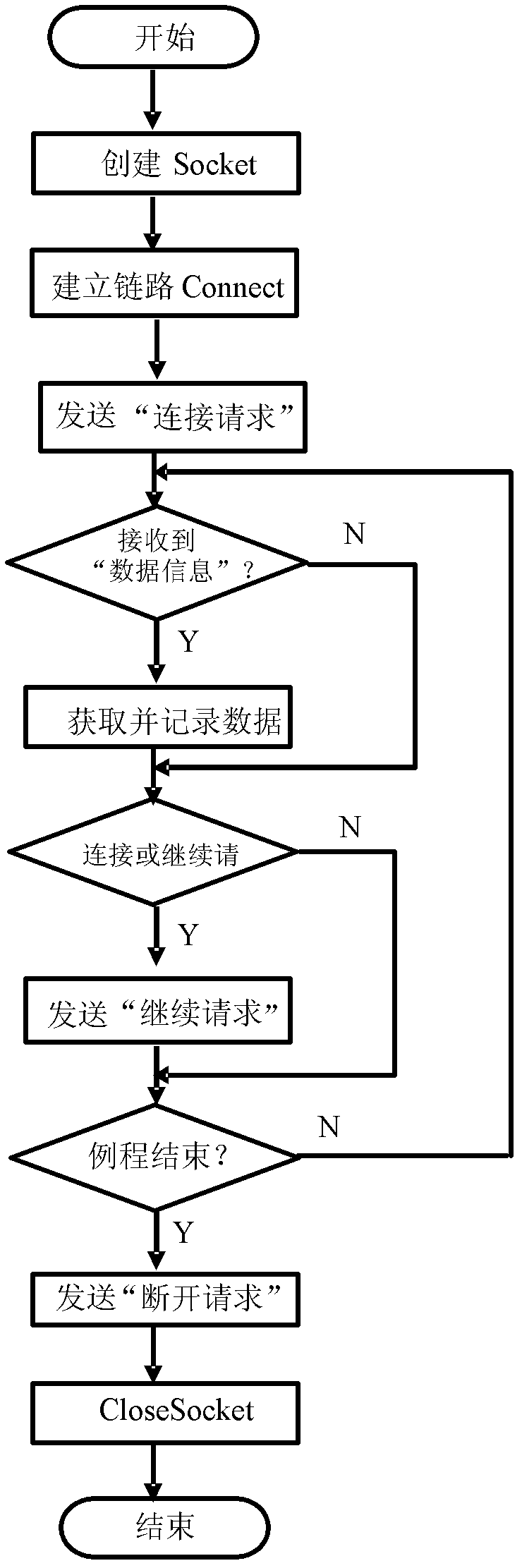

[0050] The new data chan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com