Ion implanter

A technology of ion implanter and reaction chamber, which is applied in the manufacture of electrical components, circuits, semiconductors/solid-state devices, etc. It can solve the problems of high temperature, complex principle and structure, expensive purchase and maintenance, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

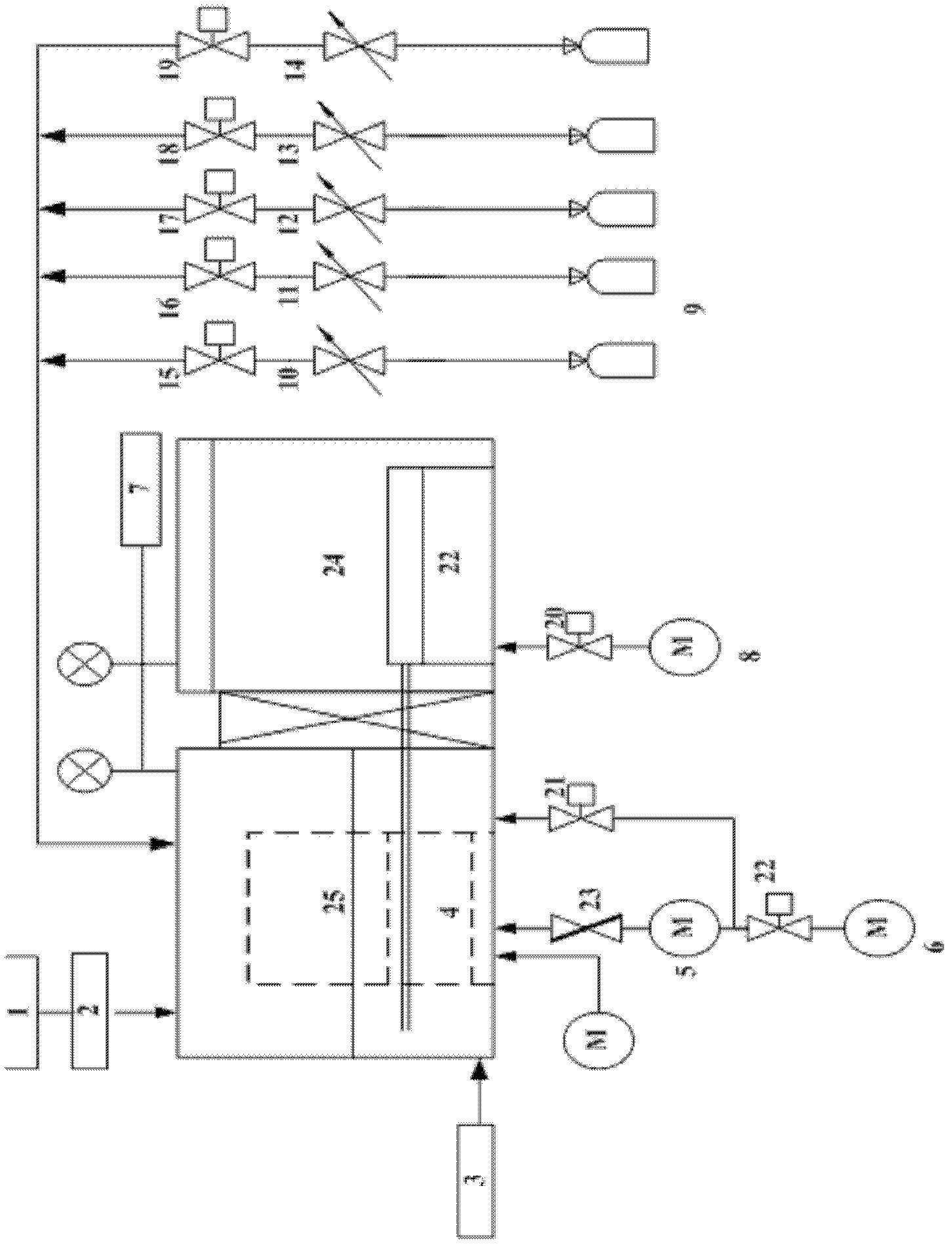

[0011] see figure 1 , an ion implanter provided by an embodiment of the present invention includes a vacuum system, a sheet feeding system, a gas feeding system, and a power supply system.

[0012] Wherein, the radio frequency power supply system includes a radio frequency power supply 1 , a radio frequency power supply matcher 2 and a pulse power supply 3 . The RF power supply 1 provides the energy required by the plasma for the reaction. The pulse power supply 3 provides a plasma implantation environment for the reaction.

[0013] The vacuum system includes a pre-pumping chamber 24 and a reaction chamber 25 . The reaction chamber 25 is connected with the pre-pumping chamber 24 by a gate valve. Wherein, the pre-pumping chamber 24 is a space for placing and transporting silicon wafers, its pressure can be changed between atmospheric pressure and low vacuum, and the vacuum can be obtained by a mechanical pump. The reaction chamber 25 requires a higher vacuum environment, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com