System and method for reduction of water consumption in purified terephthalic acid production

A technology of terephthalic acid and p-toluic acid, applied in chemical instruments and methods, separation methods, organic chemical methods, etc., to achieve the effect of easy installation and increased capital expenditure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

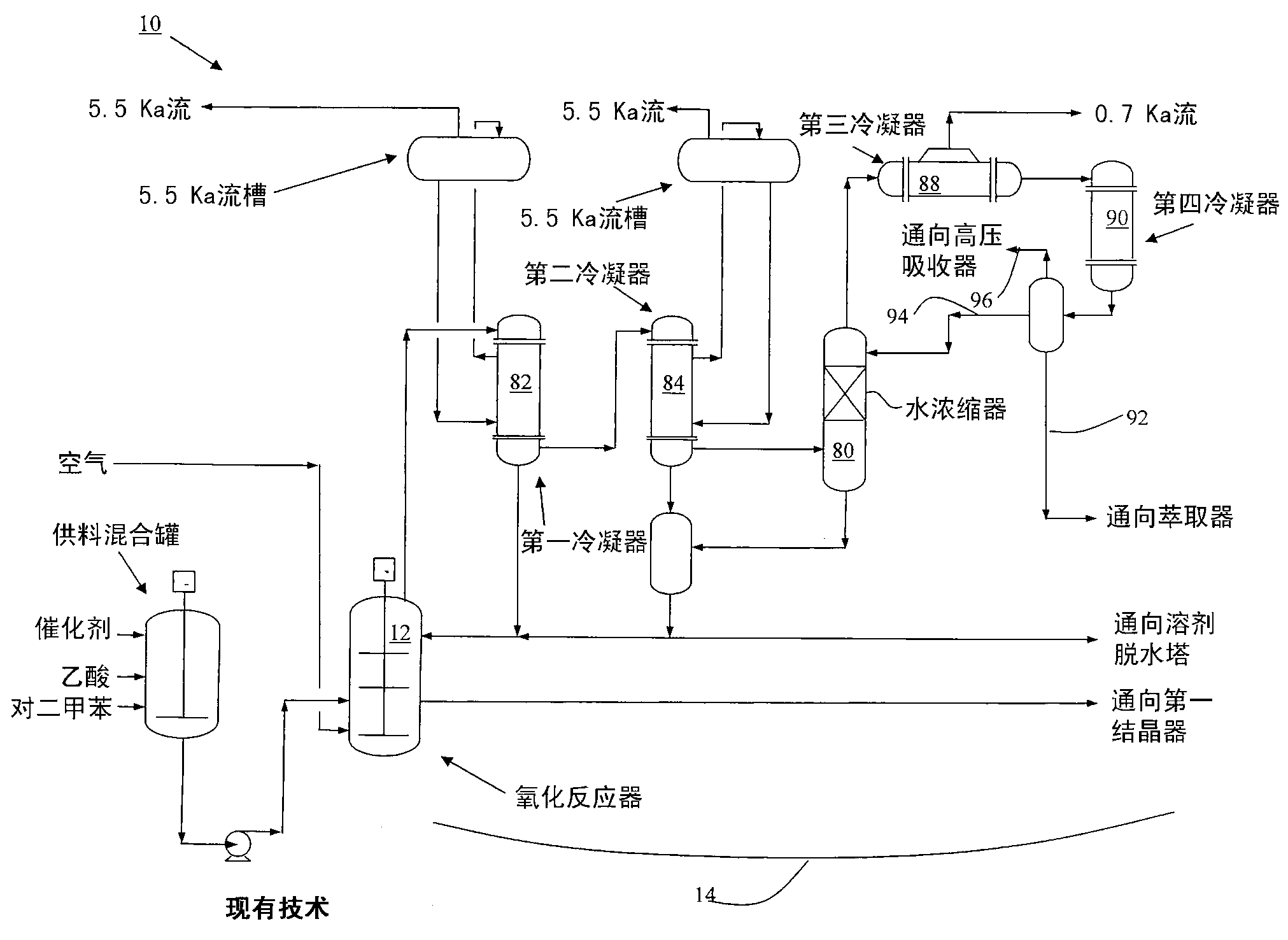

[0114] Table 2. Contents of different streams in a typical prior art acetic acid recovery system, such as figure 2 shown.

[0115]

[0116]

Embodiment 2

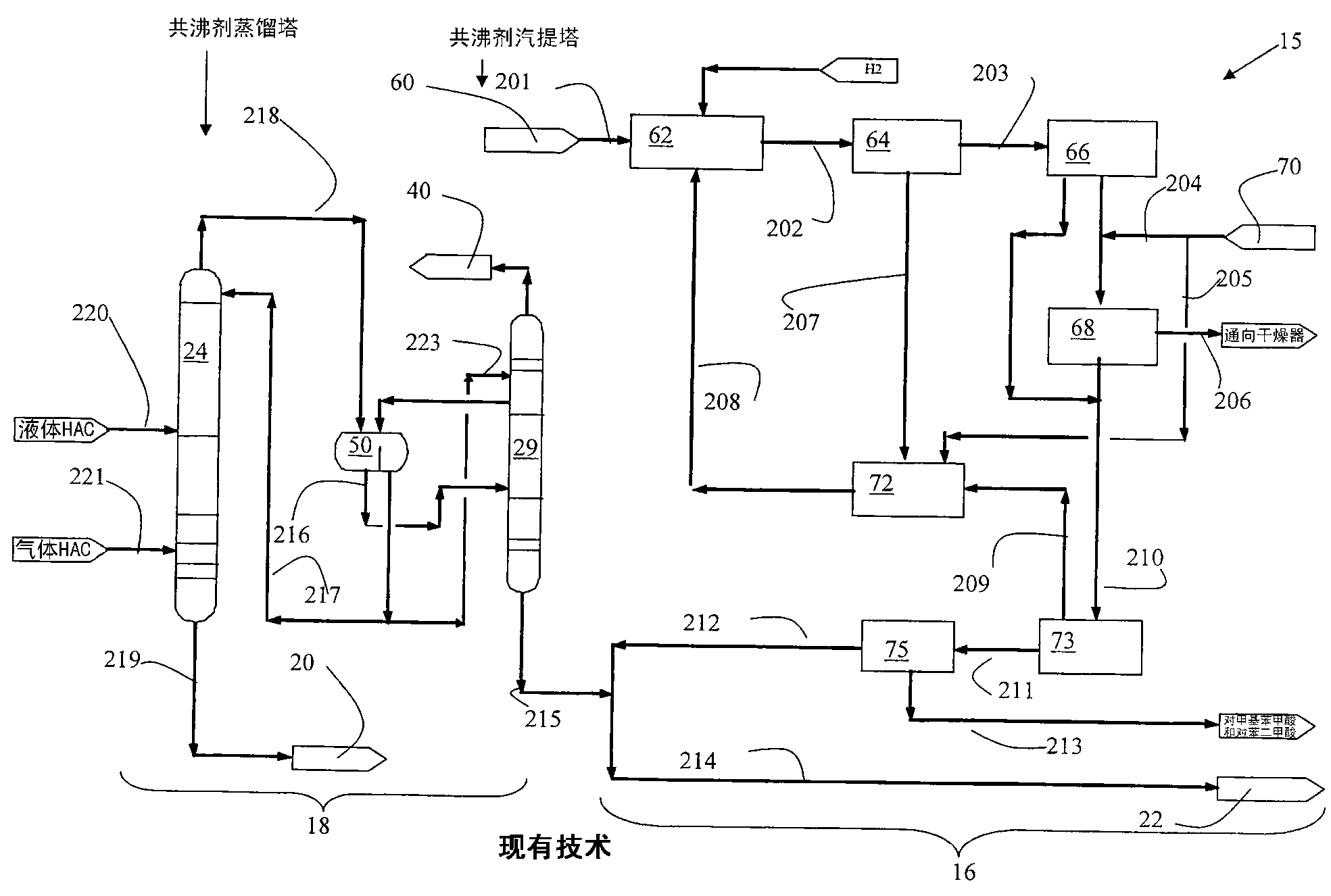

[0118] Table 3. Contents of various streams in a prior art acetic acid recovery system modified from Ohkoshi et al., as image 3 shown.

[0119]

[0120]

Embodiment 3

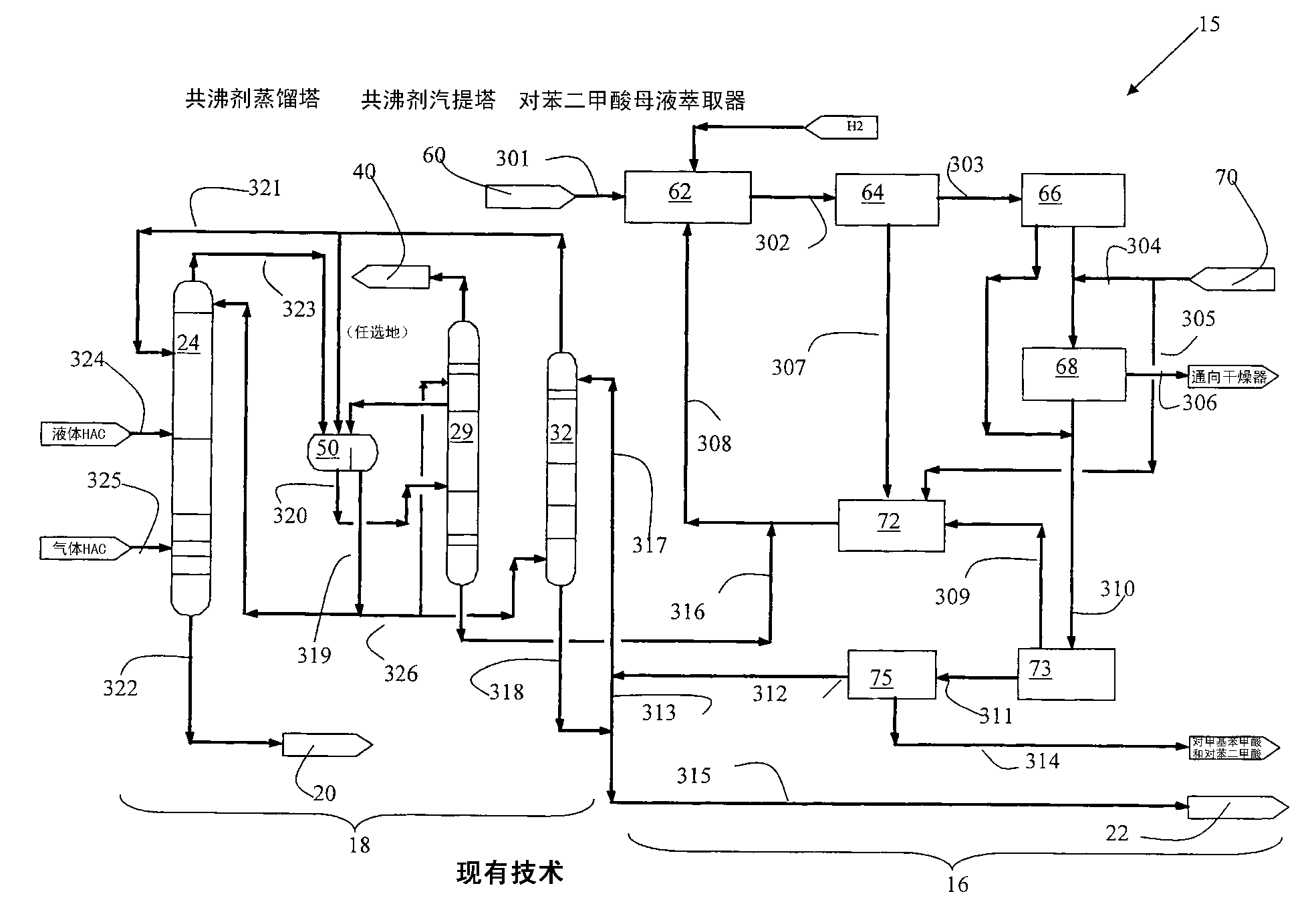

[0122] Table 4. Contents of various streams in the application process for recovery of acetic acid and water from aqueous streams, such as Figure 4 shown.

[0123]

[0124]

[0125]

[0126] These results are summarized in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com