Degradation method of plastic foam

A technology of plastic foam and feed, applied in the direction of animal feed, animal feed, application, etc., can solve problems such as a large number of toxic gases, polluted air, etc., and achieve the effect of realizing waste utilization, cost saving, and simple operation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

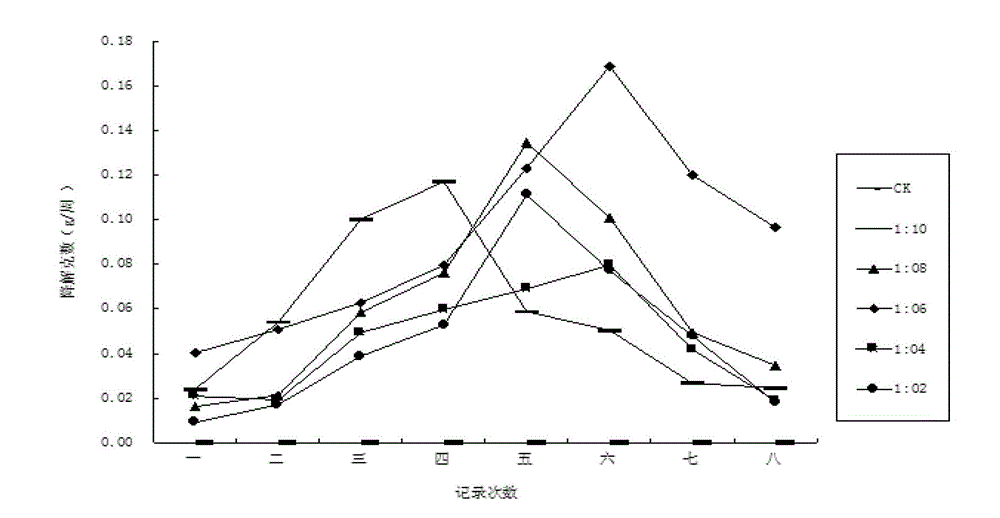

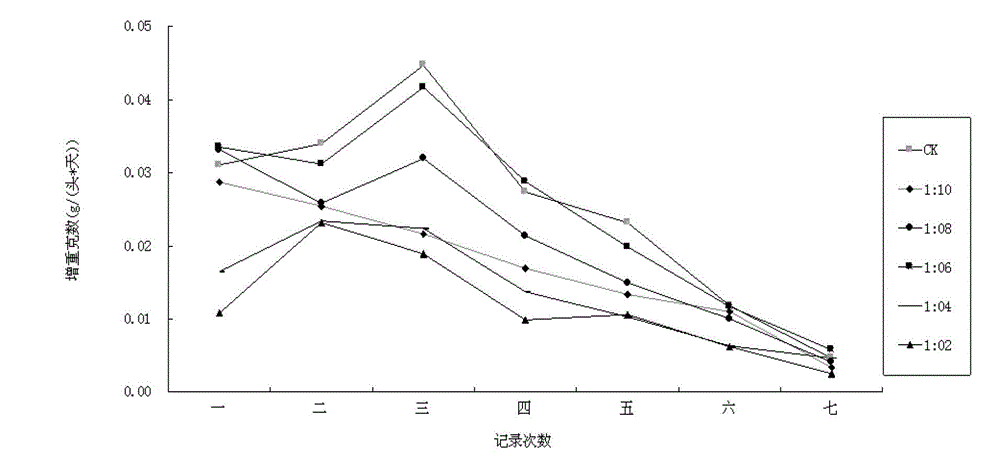

[0016] Put 40 Tenebrio molitors in each petri dish, mix plastic foam and bran at a mass ratio of 1:10, 1:8, 1:6, 1:4 and 1:2 respectively to prepare feed and cultivate under constant temperature and light Tenebrio molitor was raised in the box, and the light control in the constant temperature light incubator was 14L:10D, the relative humidity was 70%, and the temperature was 25°C. Put a small amount of cabbage leaves of equal quality in each petri dish, and spray water appropriately to ensure the humidity. Add a group of blank control, only add bran, each group has 3 repetitions.

[0017] Weigh the quality of Tenebrio molitor and the reduction of plastic foam in each petri dish once every 7 days, and record the number of deaths of Tenebrio molitor in the petri dish, calculate the average weight and average gain of each group, and all weighing data are reserved for 5 days. significant digits.

[0018] Observe the development progress of Tenebrio molitor at 8:00, 15:00, and 22...

Embodiment 2-3

[0040] Referring to Example 1, the process conditions different from Example 1 and related parameters are shown in Table 3.

[0041] The technological parameter of table 3 embodiment 2-3 and related data

[0042]

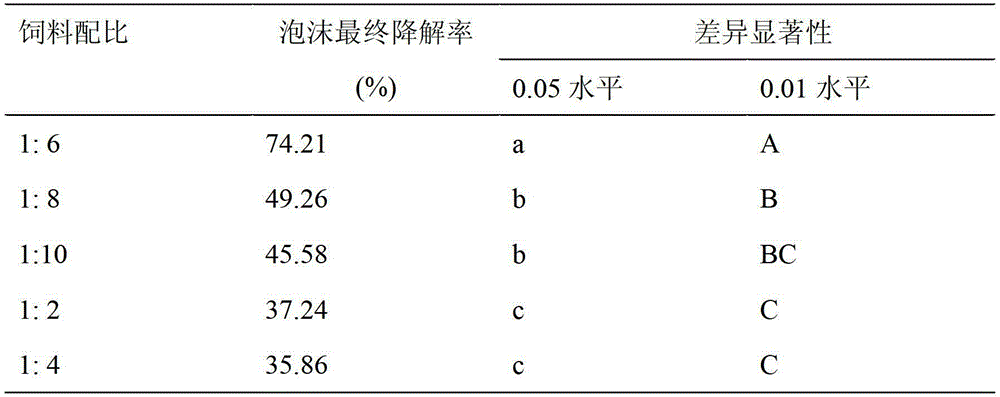

[0043] The method for degrading the plastic foam of the present invention is to feed the Tenebrio molitor by mixing the plastic foam and bran to prepare feed, and use the Tenebrio molitor to degrade the plastic foam, which is environmentally friendly and economical, and has a simple operation method. The optimal feed ratio of Tenebrio molitor is foam:bran=1:6, that is, when 14.28% foam is added to the feed, the growth status of Tenebrio molitor and the degradation of foam are optimal, which provides a basis for environmental protection. Theoretical data and experimental support, so that when the population of Tenebrio molitor is enlarged by raising a large number of Tenebrio molitor indoors, waste utilization can be realized to the maximum extent, cost can be sav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com