Flavoured fermented milk and preparation method thereof

A fermented milk and flavor technology, applied in dairy products, milk preparations, applications, etc., can solve problems such as single taste, achieve rich nutrition, solve the effect of single taste and low active ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

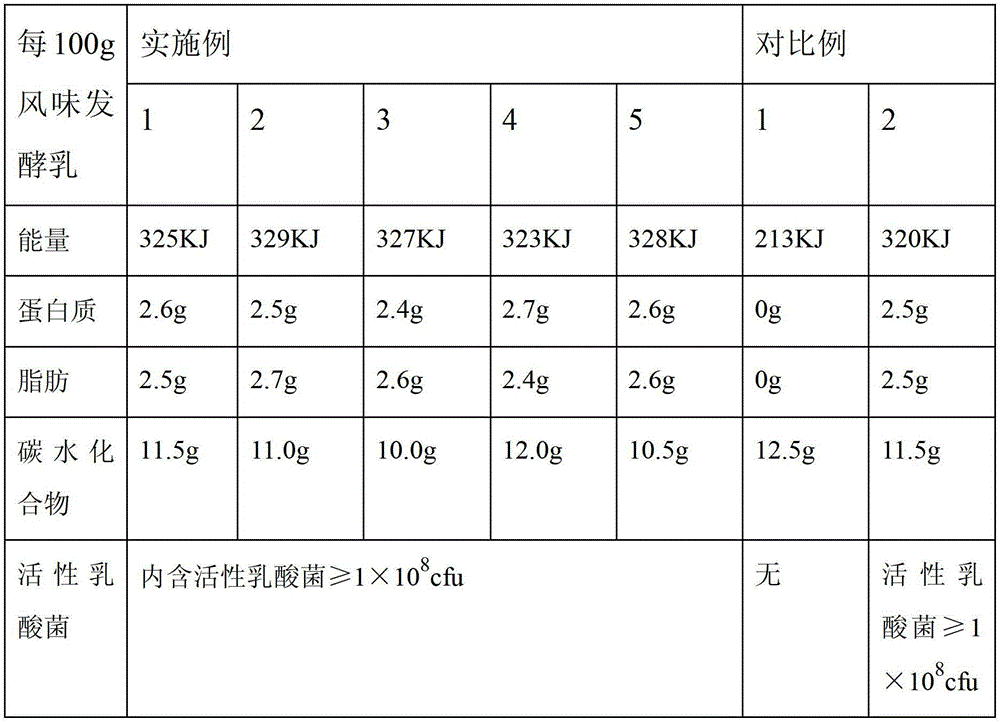

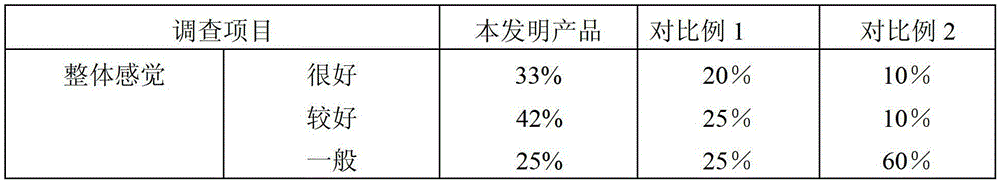

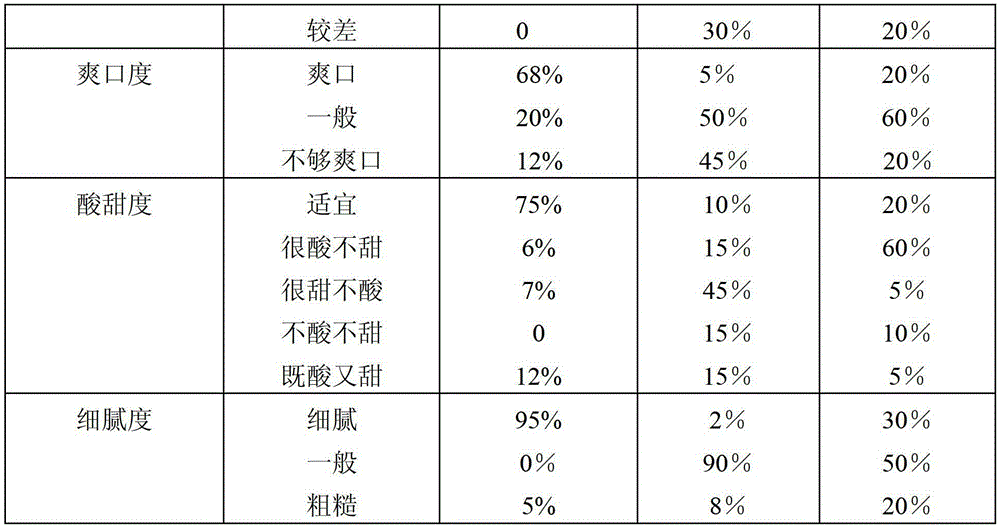

Examples

Embodiment 1

[0031] A flavored fermented milk and a preparation method thereof, comprising the following steps:

[0032] (1) Heat 800g of standardized antibiotic-free milk to 50°C, add 10g of concentrated whey protein powder with a protein content of 30%, 45g of white sugar, and 10g of rock sugar in proportion. Concentrated pear juice 2g, dilute to 1000g with standardized antibiotic-free milk, and cool to 8°C after distilling;

[0033] (2) Use a high-pressure homogenizer to homogenize and refine the material obtained in step (1) at a pressure of 19 MPa and a temperature of 65°C, then use a tubular sterilization device to sterilize the material at 95°C for 300 seconds;

[0034] (3) Cool the material obtained in step (2) to 43°C, and freeze-dry the bacteria at 100U / ton. The components of the freeze-dried bacteria are Streptococcus thermophilus and Lactobacillus bulgaricus, and dissolve them in aseptic skim milk. The mass percentage concentration is 15%, fermented at a temperature of 43°C, a...

Embodiment 2

[0039] A flavored fermented milk and a preparation method thereof, comprising the following steps:

[0040] (1) Heat 800g of standardized antibiotic-free milk to 45°C, add 10g of concentrated whey protein powder with a protein content of 30%, 45g of white sugar, and 10g of rock sugar in proportion, stir and mix for 30 minutes, then add Baumé to a temperature of 69.8°B Concentrated pear juice 1.5g, dilute to 1000g with standardized antibiotic-free milk, and cool to 6°C after distilling;

[0041] (2) Use a high-pressure homogenizer to homogenize and refine the material obtained in step (1) at a pressure of 19 MPa and a temperature of 65°C, then use a tubular sterilization device to sterilize the material at 95°C for 300 seconds;

[0042] (3) Cool the material obtained in step (2) to 43°C, and freeze-dry the bacteria at 100U / ton. The components of the freeze-dried bacteria are Streptococcus thermophilus and Lactobacillus bulgaricus, and dissolve them in aseptic skim milk. The ma...

Embodiment 3

[0047] A flavored fermented milk and a preparation method thereof, comprising the following steps:

[0048] (1) Heat 800g of standardized antibiotic-free milk to 45°C, add 10g of concentrated whey protein powder with a protein content of 30%, 45g of white sugar, and 10g of rock sugar in proportion. Concentrated pear juice 1.5g, dilute to 1000g with standardized antibiotic-free milk, and cool to 5°C after distilling;

[0049] (2) Use a high-pressure homogenizer to homogenize and refine the material obtained in step (1) with a pressure of 19MPa and a temperature of 65°C, and then use an ultra-high temperature tubular sterilization equipment to sterilize the material at 95°C 300 seconds;

[0050] (3) Cool the material obtained in step (2) to 43°C, and freeze-dry the bacteria at 100U / ton. The components of the freeze-dried bacteria are Streptococcus thermophilus and Lactobacillus bulgaricus, and dissolve them in aseptic skim milk. The mass percentage concentration is 20%, fermen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com