Aspirin slow release tablet and preparation method thereof

A technology of aspirin and sustained-release tablets, which is applied in the direction of pharmaceutical formulations, medical preparations with non-active ingredients, medical preparations containing active ingredients, etc., which can solve waste, affect the clinical use of drugs, and the release rate of sustained-release tablets is unstable, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

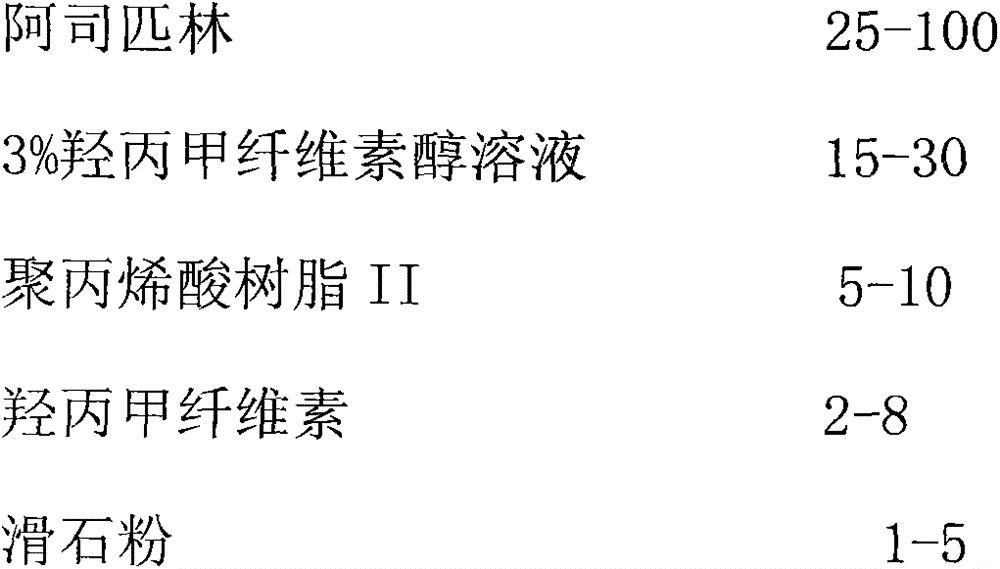

Image

Examples

Embodiment 1

[0047] (1) Prepare 3% hypromellose alcohol solution:

[0048] (1), 3% hypromellose alcohol solution prescription

[0049] Tartaric acid 2.5kg water 10.00kg polysorbate 801.0kg

[0050] Hypromellose 1.5kg 95% Ethanol 32.0kg

[0051] (2), take tartaric acid, water, polysorbate 80, hypromellose, 95% ethanol. Dissolve tartaric acid in water, heat to 70°C and stir to dissolve completely, then add polysorbate 80, stir to dissolve completely; add hypromellose while stirring to make it evenly dispersed in 95% ethanol ; Pour the above two solutions together and mix evenly, and place at 18-26°C for 8 hours to 72 hours.

[0052] The above tartaric acid, water, polysorbate 80, hypromellose, and 95% ethanol should meet the requirements of "The Pharmacopoeia of the People's Republic of China 2010 Edition Part Two", and require that the fineness of hypromellose can all pass through an 80-mesh sieve , viscosity 55mPa·s,

[0053] (2) Granulation

[0054] (1), prescription

[0055] Aspir...

Embodiment 2

[0062] (1) Prepare 3% hypromellose alcohol solution:

[0063] (1), 3% hypromellose alcohol solution prescription

[0064] Tartaric acid 2.25kg water 6.00kg polysorbate 800.6kg

[0065] Hypromellose 0.9kg 95% Ethanol 19.2kg

[0066] (2), take tartaric acid, water, polysorbate 80, hypromellose, 95% ethanol. Dissolve tartaric acid in water, heat to 70°C and stir to dissolve completely, then add polysorbate 80, stir to dissolve completely; add hypromellose while stirring to make it evenly dispersed in 95% ethanol ; Pour the above two solutions together and mix evenly, and place at 18-26°C for 8 hours to 72 hours.

[0067] The above tartaric acid, water, polysorbate 80, hypromellose, and 95% ethanol should meet the requirements of "The Pharmacopoeia of the People's Republic of China 2010 Edition Part Two", and require that the fineness of hypromellose can all pass through an 80-mesh sieve , viscosity 55mPa·s,

[0068] (2) Granulation

[0069] (1), prescription

[0070] Aspir...

Embodiment 3

[0077] (1) Prepare 3% hypromellose alcohol solution:

[0078] (1), 3% hypromellose alcohol solution prescription

[0079] Tartaric acid 2.25kg water 6.00kg polysorbate 800.6kg

[0080] Hypromellose 0.9kg 95% Ethanol 19.2kg

[0081] (2), take tartaric acid, water, polysorbate 80, hypromellose, 95% ethanol. Dissolve tartaric acid in water, heat to 70°C and stir to dissolve completely, then add polysorbate 80, stir to dissolve completely; add hypromellose while stirring to make it evenly dispersed in 95% ethanol ; Pour the above two solutions together and mix evenly, and place at 18-26°C for 8 hours to 72 hours.

[0082] The above tartaric acid, water, polysorbate 80, hypromellose, and 95% ethanol should meet the requirements of "The Pharmacopoeia of the People's Republic of China 2010 Edition Part Two", and require that the fineness of hypromellose can all pass through an 80-mesh sieve , viscosity 60mPa·s,

[0083] (2) Granulation

[0084] (1), prescription

[0085] Aspir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com