Lead-cadmium compound conditioner for rice field soil as well as preparation and application methods thereof

A technology of soil improvement and improver, which is applied in the restoration of polluted soil, etc., to achieve the effects of increasing yield, simple preparation, and high operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Weigh the raw materials with the following qualities;

[0035] Calcium carbonate, 30%; Hydroxyapatite, 10%; Sepiolite, 30%; Zeolite, 30%; Among them, calcium carbonate is light calcium carbonate, whiteness > 90, particle size > 200 mesh, sedimentation volume (2.4 -2.8 mL / g); calcium content in hydroxyapatite composition is 22%-27%, phosphorus content is 9%-12%, particle size > 200 mesh; sepiolite composition > 80%, sedimentation value 800-850, water content 200 mesh; zeolite is artificial zeolite, particle size > 200 mesh;

[0036] Stir the above raw materials continuously for 30 minutes in the stirring device, and avoid adding water during stirring to make a lead-cadmium composite improver;

[0037] Arrange 5 sampling points according to the plum blossom pattern, collect 0-20cm surface soil, and mix evenly; the soil is naturally air-dried to remove debris, crushed and screened with a 0.149 mm nylon sieve; the total amount of lead and cadmium is used HCl-HNO 3 -HClO ...

Embodiment 2

[0044] Compared with Example 1, the present embodiment differs in that the quality of each raw material is:

[0045] Calcium Carbonate, 50%; Hydroxyapatite, 5%; Sepiolite, 20%; Zeolite, 25%;

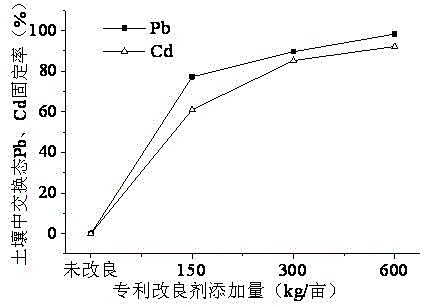

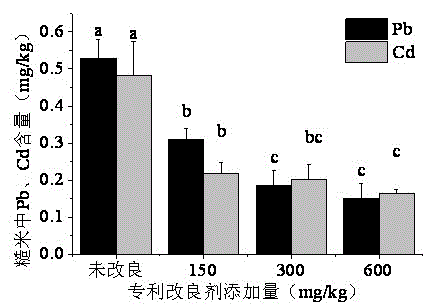

[0046] After the paddy field is improved, the exchange state content of heavy metal lead and cadmium in paddy field soil can be reduced by 97% and 94% respectively; the content of heavy metal lead and cadmium in rice can be reduced by 30% and 32% respectively; the yield of rice can be significantly increased 30%.

Embodiment 3

[0048] Compared with Example 1, the present embodiment differs in that the quality of each raw material is:

[0049] Calcium Carbonate, 40%; Hydroxyapatite, 10%; Sepiolite, 30%; Zeolite, 20%;

[0050] After improving the paddy field, the exchange state content of heavy metal lead and cadmium in paddy field soil can be reduced by 99% and 97% respectively; the content of heavy metal lead and cadmium in rice can be reduced by 45% and 36% respectively; the yield of rice can be significantly increased 35%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Sedimentation volume | aaaaa | aaaaa |

| Moisture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com