Circulating air bed device for modification of titanium concentrate

A technology of circulating air flow and titanium concentrate, which is applied in the directions of titanium dioxide, titanium oxide/hydroxide, chemical instruments and methods, etc., can solve the problem that fluidized bed materials are prone to channeling and surging, and the particle size requirements of titanium concentrate raw materials are high. , narrow adaptability of raw material particle size range, etc., to achieve the effect of shortening production cycle, large contact area between gas and solid phases, and good heat and mass transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

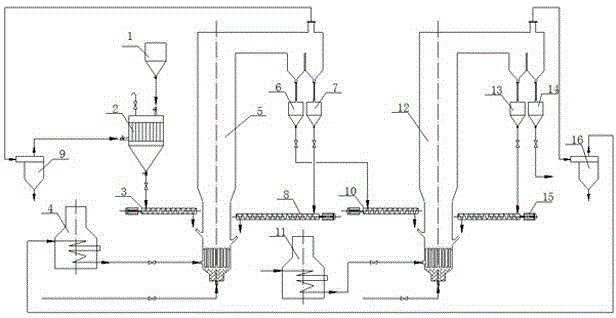

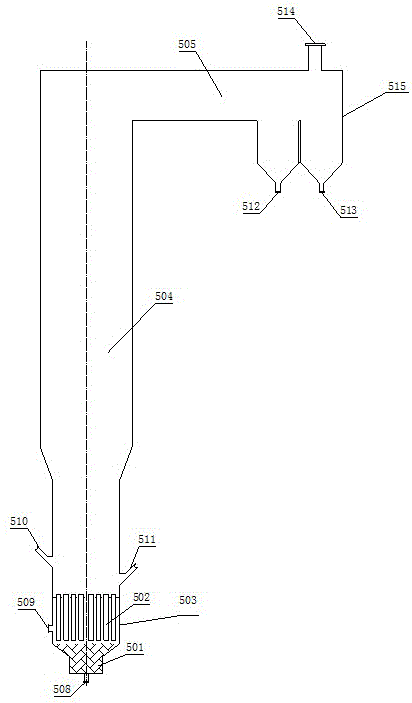

[0057] In order to understand the purpose, technical solutions and beneficial effects of the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following examples.

[0058] The invention provides a circulating air flow bed device for modifying titanium concentrate in the production of artificial rutile. In the present invention, since the titanium concentrate uses hot air as the carrier, the contact area between the gas and solid phases is large, the contact is sufficient, and the heat and mass transfer effect is good. Therefore, it has strong raw material adaptability, sufficient and rapid response, simple operation, and low energy consumption The advantages of low cost and continuous production. The invention utilizes the difference in projecting distance of materials with different specific gravity, and by adjusting the fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com