Method for separating and purifying recombinant protein A

A technology for separation, purification and recombinant protein, applied in the field of purification of recombinant protein A, can solve the problems of high cost, low protein recovery rate, low recovery rate, etc., and achieve the effect of low cost and high protein recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

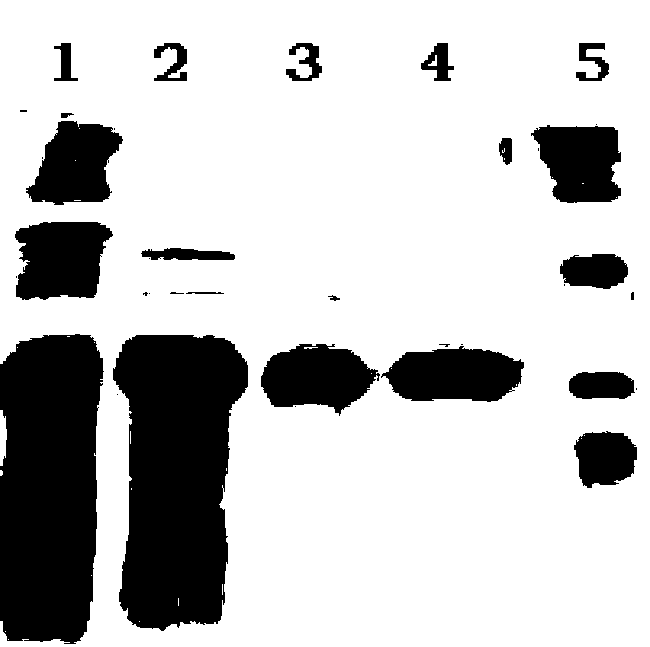

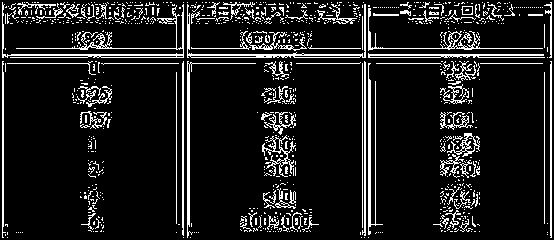

[0039] Example 1: Endotoxin removal by activated carbon adsorption

[0040] 1) Take 700g of bacteria containing recombinant protein A, add 2800 mL of PBS buffer (containing 8.0mM disodium hydrogen phosphate, 2.0mM potassium dihydrogen phosphate, 131mM NaCl) according to the mass:volume ratio of 1:4, and stir well Dissolve the bacteria, then add lysozyme to a concentration of 1 mg / ml, stir in a water bath at 60°C for 1 hour, then place in a boiling water bath and stir for 30 minutes, and centrifuge after cooling to obtain a broken supernatant;

[0041] 2) Divide the crushed supernatant into 7 equal parts, add NaCl to each part until the concentration increases by 0.3mol / L, add Triton X-100 to the concentrations of 0, 0.25%, 0.5%, 1%, 2%, 4%, 6%, respectively % (v / v), after stirring evenly, add 4% activated carbon according to the mass:volume ratio, put it in a 60°C water bath and stir for 4 hours for the first adsorption, and centrifuge to obtain the supernatant solution;

[0...

Embodiment 2

[0045] Embodiment 2: Removal of endotoxin by hydrophobic chromatography

[0046] 1) Take 100g of bacteria containing recombinant protein A, add 400mL of PBS buffer (containing

[0047] 8.0mM disodium hydrogen phosphate, 2.0mM potassium dihydrogen phosphate, 131mM NaCl), stir well to dissolve the bacteria, then add lysozyme to a concentration of 1mg / ml, stir in a water bath at 60°C for 1h, then place in a boiling water bath and stir for 30min , after cooling, centrifuge to obtain broken supernatant;

[0048] 2) Add NaCl to the crushed supernatant until the concentration increases to 0.3mol / L, add Triton X-100 to a concentration of 0.5% (v / v), stir evenly, add 4% activated carbon according to the mass:volume ratio, and place in a 60°C water bath Stir for 4 hours for the first adsorption, and centrifuge to obtain a supernatant solution;

[0049] 3) Then add NaCl until the concentration increases by 0.3mol / L, add Triton X-100 until the concentration increases by 0.5% (v / v), sti...

Embodiment 3

[0053] Embodiment 3: Removal of endotoxin by hydrophobic chromatography

[0054] 1) Take 100g of bacteria containing recombinant protein A, add 400mL of PBS buffer (containing

[0055] 8.0mM disodium hydrogen phosphate, 2.0mM potassium dihydrogen phosphate, 131mM NaCl), stir well to dissolve the bacteria, then add lysozyme to a concentration of 1mg / ml, stir in a water bath at 60°C for 1h, then place in a boiling water bath and stir for 30min , after cooling, centrifuge to obtain broken supernatant;

[0056] 2) Add NaCl to the crushed supernatant to increase the concentration to 0.3mol / L, add Triton X-100 to a concentration of 2% (v / v), stir evenly, add 4% activated carbon according to the mass:volume ratio, and place in a 60°C water bath Stir for 4 hours for the first adsorption, and centrifuge to obtain a supernatant solution;

[0057] 3) Then add NaCl until the concentration increases by 0.3mol / L, add Triton X-100 until the concentration increases by 2% (v / v), stir evenly,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com