Insulating impregnating resin for drawing groove wedge and its curing method

An insulating impregnation and resin technology, which is applied in the field of insulating impregnating resin and curing for the wedge of drawing and pulling, can solve the problems of inability to meet the needs of electrical equipment, and achieve the effects of low use cost, good insulation performance and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

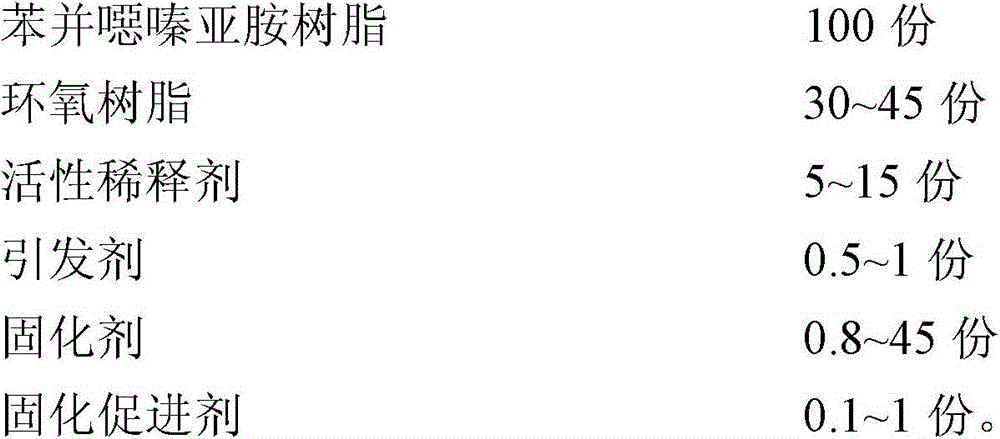

[0033] According to the formula of the insulating impregnating resin for drawing slot wedges of this embodiment:

[0034] Benzoxazine imine resin 100g, F51 novolac epoxy resin 45g, initiator benzoyl peroxide (BPO) 0.8g, reactive diluent is styrene 10g, curing agent is 594 epoxy curing agent 0.8g, accelerator It is 0.5g of aluminum acetylacetonate.

[0035] After the above-mentioned components are uniformly mixed according to the formula, the insulating resin for high-temperature-resistant lead-out slot wedges is obtained. When the insulating resin is used, the mold is heated to 180° C. in the curing step, and the resin stays in the mold for 30 seconds. After the curing step at high temperature, the insulating material is formed.

Embodiment 2

[0037] According to the formula of the insulating impregnating resin for drawing slot wedges of this embodiment:

[0038] Benzoxazine imine resin 100g, F44 novolac epoxy resin 45g, initiator benzoyl peroxide (BPO) 1.0g, reactive diluent are diethylene glycol diacrylate phthalate 10g, curing agent is formazan 45 g of tetrahydrophthalic anhydride, and 0.5 g of aluminum acetylacetonate as the accelerator.

[0039] After the above-mentioned components are uniformly mixed according to the formula, the insulating resin for high-temperature-resistant lead-out slot wedges is obtained. When the insulating resin is used, the mold is heated to 170° C. in the curing step, and the resin stays in the mold for 30 seconds. After the curing step at high temperature, the insulating material is formed.

Embodiment 3

[0041] According to the formula of the insulating impregnating resin for drawing slot wedges of this embodiment:

[0042] Benzoxazine imine resin 100g, F44 novolac epoxy resin 30g, initiator benzoyl peroxide (BPO) 0.6g, reactive diluent is pentaerythritol triacrylate (APE) 15g, curing agent is phenylimidazole 8g, The accelerator is 0.2 g of cobalt acetylacetonate.

[0043] After the above-mentioned components are uniformly mixed according to the formula, the insulating resin for high-temperature-resistant lead-out slot wedges is obtained. When the insulating resin is used, the mold is heated to 180° C. in the curing step, and the resin stays in the mold for 45 seconds. After the curing step at high temperature, the insulating material is formed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com