Coating for protecting fair-faced concrete and construction technology thereof

A technology of fair-faced concrete and coatings, applied in the direction of coatings, etc., can solve problems such as large gaps, lack of decorativeness in concrete, pan-alkali, etc., and achieve the effect of preventing uneven gloss and maintaining natural texture and texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

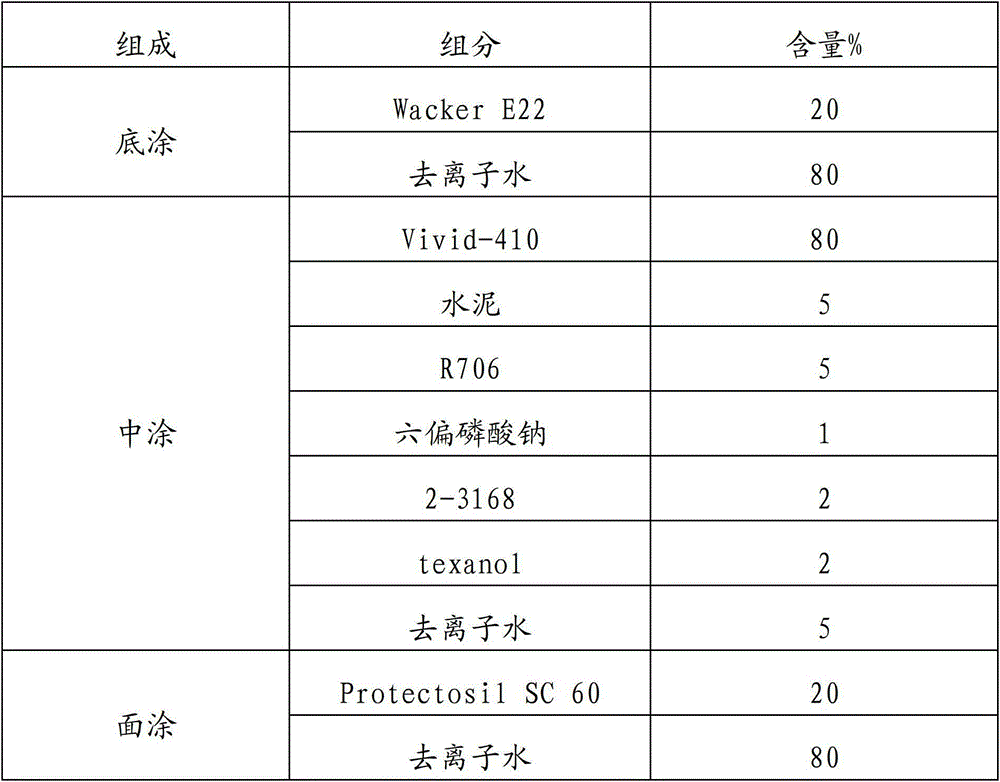

[0029] A kind of coating that is used for fair-faced concrete protection, its formula is shown in Table 1.

[0030] Table 1

[0031]

[0032] Among the above:

[0033] Wacker E22 silicone polymer emulsion, produced by Wacker;

[0034] Vivid-40 self-crosslinking acrylic acid polymer emulsion, produced by XX company;

[0035] R706, rutile titanium dioxide, produced by DuPont;

[0036] Protectosil SC60 fluorosilicone polymer supplied by Evonik Degussa.

[0037] The preparation method of the product is as follows:

[0038] Add deionized water to the reaction kettle, add Wacker E22 or Protectosil SC60 under the action of stirring, and keep stirring for 30 minutes after the dispersion is uniform, to obtain the primer or top coat in the paint.

[0039] Add deionized water to the reaction kettle, add sodium hexametaphosphate, 2-3168, texanol in turn under stirring, when one component is dispersed or dissolved evenly, the next component can be added, when all components are eve...

Embodiment 2

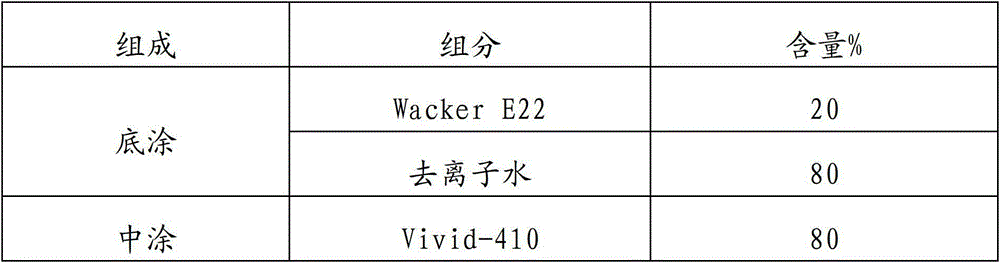

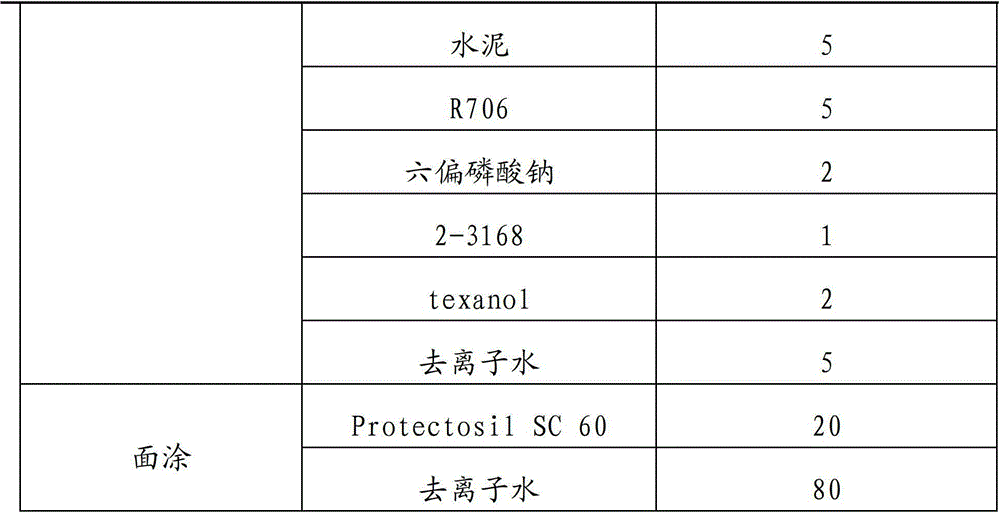

[0046] With reference to embodiment 1, a kind of coating that is used for fair-faced concrete protection, its formula is shown in Table 2.

[0047] Table 2

[0048]

[0049]

[0050] The preparation method of the product is as follows:

[0051] Add deionized water to the reaction kettle, add Wacker E22 or Protectosil SC60 under the action of stirring, and keep stirring for 30 minutes after the dispersion is uniform, to obtain the primer or top coat in the paint.

[0052] Add deionized water to the reaction kettle, add sodium hexametaphosphate, 2-3168, texanol in turn under stirring, when one component is dispersed or dissolved evenly, the next component can be added, when all components are evenly dispersed , keep stirring at a speed of 750rpm for 5 minutes, after completion, add cement and R706 in turn under the action of stirring, when one component is evenly dispersed, the next component can be added, when all components are evenly dispersed, at a speed of 1000-1500r...

Embodiment 3

[0059] With reference to embodiment 2, a kind of coating that is used for fair-faced concrete protection, its formula is shown in table 3.

[0060] table 3

[0061]

[0062] The preparation method of the product is as follows:

[0063] Add deionized water to the reaction kettle, add Wacker E22 or Protectosil SC60 under the action of stirring, and keep stirring for 30 minutes after the dispersion is uniform, to obtain the primer or top coat in the paint.

[0064]Add deionized water to the reaction kettle, add sodium hexametaphosphate, 2-3168, texanol in turn under stirring, when one component is dispersed or dissolved evenly, the next component can be added, when all components are evenly dispersed , keep stirring at a speed of 750rpm for 5 minutes, after completion, add cement and R706 in turn under the action of stirring, when one component is evenly dispersed, the next component can be added, when all components are evenly dispersed, at a speed of 1000-1500rpm Keep stir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com