Mining winter cooling and mine heat utilization system

A mine-used and ore-thermal technology, applied in mining equipment, mine/tunnel ventilation, earthwork drilling, etc., can solve problems such as waste of electric energy, achieve good cooling effect, stable cooling performance, and low investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

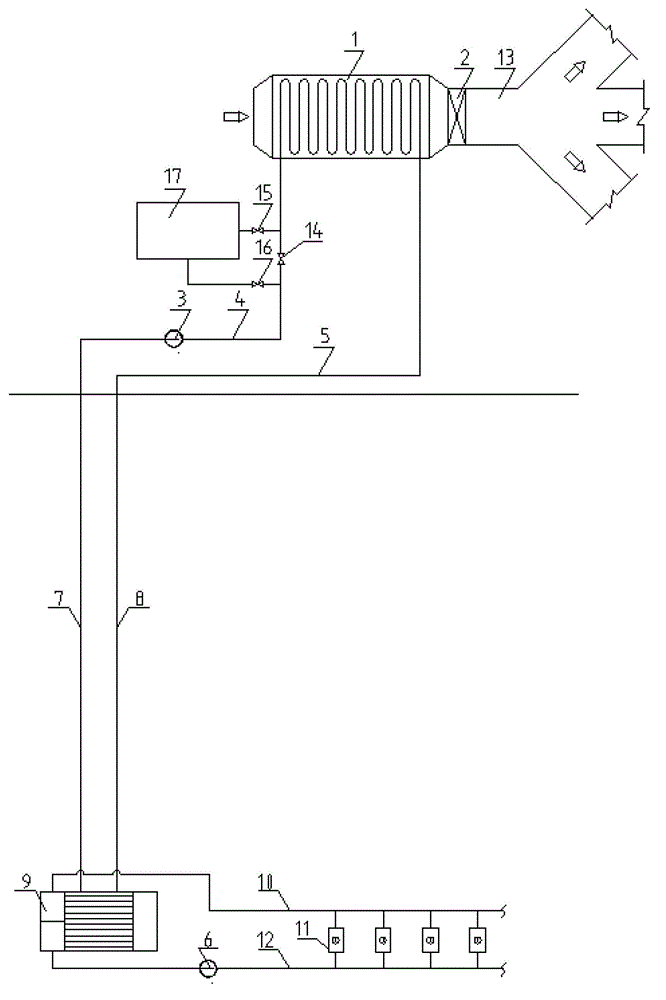

[0012] With reference to accompanying drawing, the present invention is made up of dotted line in the figure, namely the surface part and underground part that surface line is divided into; The high-pressure cold water supply pipe 4 is connected to the water supply regulating valve 14, the water inlet regulating valve 15 and the chiller 17. The chiller is connected to the high-pressure cold water supply pipe 4 through the outlet regulating valve 16, and then connected to the wellbore cold water supply pipe 7 through the surface water pump 3; The water inlet pipe 10 and the low-pressure cold water return pipe 12 are connected to the mine heat exchanger 9 in the underground part, and the mine heat exchanger 9 is connected to the high-pressure combined air cooler 11 through the underground cold water inlet pipe 10 and the underground water pump 6 and the low-pressure cold water return pipe 12. The mine heat exchanger 9 is connected to the air cooler 1 through the shaft cold water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com