Capacitance type oil level measuring transducer

A sensor and capacitance technology, which is applied in the field of new capacitive oil level measurement sensors, can solve problems such as excessive dry capacitance value of the product, inability to compensate errors, large impact force of lugs or wiring rings, etc., to solve the problem of low concentric positioning accuracy , Reduce the parasitic capacitance value, improve the effect of adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the present invention is not limited to the scope of the described embodiments.

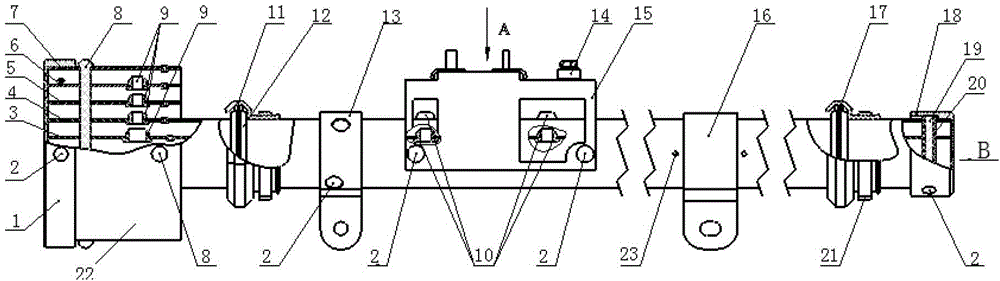

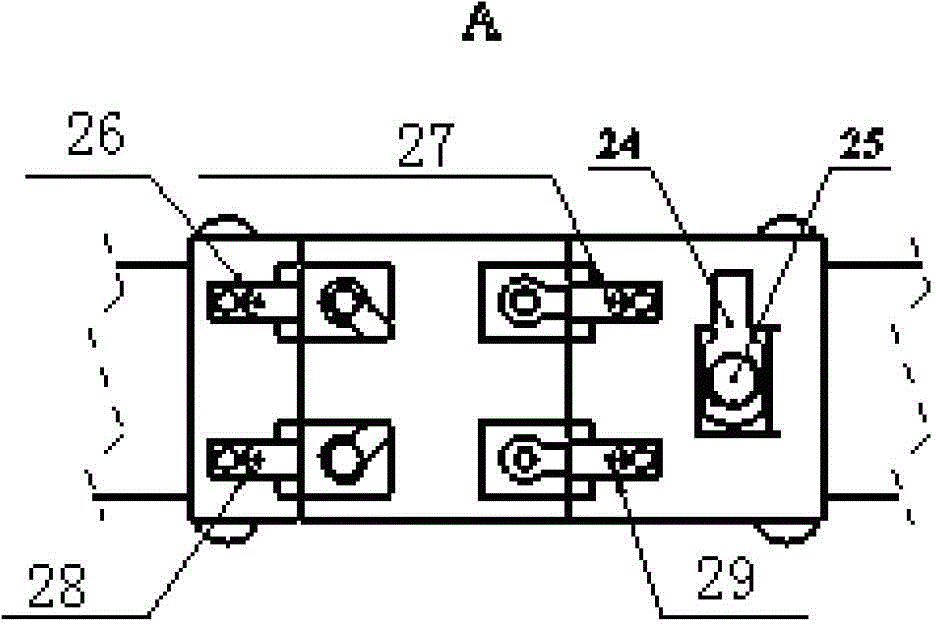

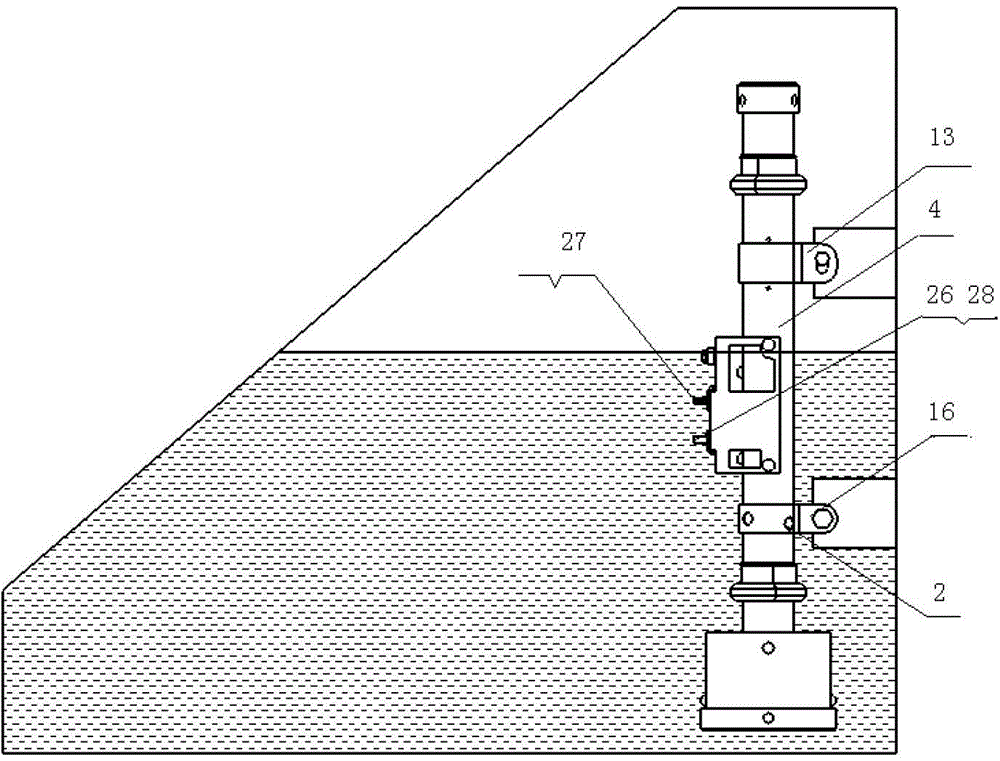

[0023] join figure 1 . The capacitive fuel level sensor provided by the present invention includes a fuel level signal main sensor 23 composed of two concentric metal pipes and a fuel dielectric coaxially connected to the head of the oil level signal main sensor 23. Constant measurement sensor 22. The fuel dielectric constant measuring sensor 22 is composed of three metal tubes concentrically wound on the head of the central tube 4 of the main sensor 23 for the fuel level height signal, and constitutes the measuring fuel dielectric constant ε 油 The three coaxial parallel capacitors, the parallel capacitors are perpendicular to each other in space, radially positioned by two compensating tube shaft pins 8 spaced up and down, and are electrically connected to the shieldi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com