Aero-engine rotor-stator rubbing position identification method based on application of cepstrum

An aero-engine and cepstrum technology, which is applied in the direction of engine testing, machine/structural component testing, measuring devices, etc., can solve problems such as inconvenient use on site, acoustic emission technology is easily affected by noise, and affects positioning accuracy, etc., to achieve The effect of simple and convenient on-site use, low additional cost, and strong anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing, the technical scheme of invention is described in detail:

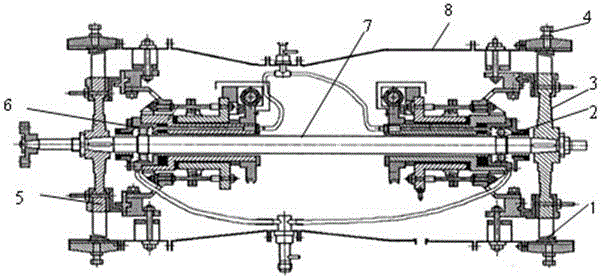

[0033] This test uses the figure 1 The shown aero-engine rotor tester realizes rubbing test. In terms of the structural design of the tester, it is first considered that the shape is consistent with the casing of the core machine of the aero-engine, and the size is reduced by three times; The adjustable stiffness support structure is designed to adjust the dynamic characteristics of the system; the multi-stage compressor is simplified to a single-stage disk structure, and a rotor-support-blask-casing system is formed structurally. The tester can realize different degrees of rubbing by adjusting the rubbing bolt 4 to squeeze the rubbing ring 1 .

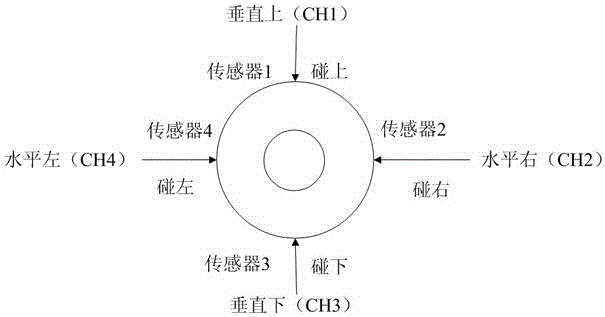

[0034] In each experiment of this embodiment, four rubbing screws are designed at the turbine case to realize rubbing experiments at four parts. The rubbing position is based on facing the turbine casing as a standard,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com