Meaty tomato chili sauce and manufacturing method thereof

A technology of tomato chili sauce and tomato sauce, which is applied in food preparation, application, food science, etc., can solve the problems of unfavorable product flavor and subsequent process production, adverse effects of tomato chili sauce flavor, long tomato processing time, etc., to achieve enhanced bioavailability Degree and health care effect, high antioxidant activity and nutritional value, scientific and reasonable production method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

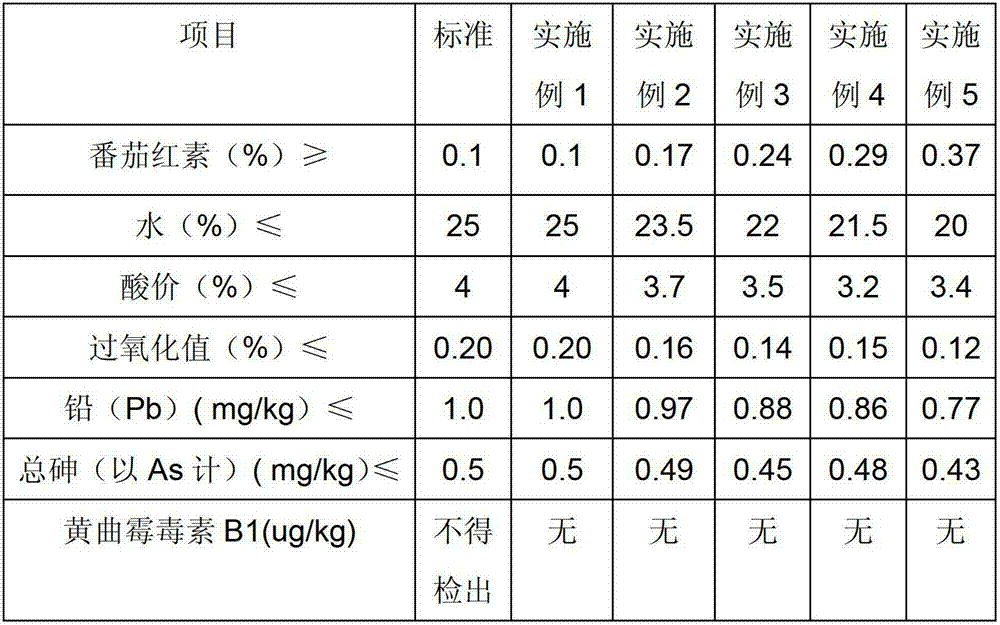

Embodiment 1

[0036] Ratio of ingredients: 500kg tomato paste, 400kg glutinous rice cake chili, 100kg minced meat, 15kg scallion, 400kg sunflower oil, 5kg ginger, 1kg salt, 0.2kg monosodium glutamate.

[0037] (1) Preparation of chili sauce: take the prescription amount of glutinous rice cake chili and carry out colloidal grinding to obtain chili sauce;

[0038] (2) Stir-fried peppers in oil: heat the sunflower oil which accounts for 40% of the total amount, control the oil temperature at 130°C, pour in the glutinous rice cake chili sauce and stir-fry until the skin of the peppers starts to turn yellow, and the oily chili sauce is obtained;

[0039] (3) Frying of minced meat: first marinate the minced meat with 0.3kg of salt, 0.5kg of rice wine, and 4kg of ginger for 0.5 hours, then add 40% of the total oil into the frying pan, and heat it over medium heat until the oil temperature is At 245°C, use a ladle to scoop the marinated minced meat into the oil along the side of the pot, stir quick...

Embodiment 2

[0044] Ingredients ratio: 520kg tomato sauce, 320kg pepper, 120kg minced meat, 20kg scallion, 620kg edible vegetable oil, 6kg ginger, 2kg salt, 0.5kg monosodium glutamate.

[0045] (1) Preparation of chili sauce: after cleaning and selecting the chili peppers, take the prescribed amount and carry out colloid grinding to obtain chili sauce;

[0046] (2) Oil-fried chili peppers: heat soybean oil which accounts for 33% of the total amount, control the oil temperature at 150°C, pour in chili sauce and stir-fry until the skin of the chili peppers starts to turn yellow to obtain oily chili sauce;

[0047] (3) Frying of minced meat: first marinate the minced meat with 0.3kg of salt, 0.5kg of rice wine, and 4kg of ginger for 0.5 hours, then add 33% of the total oil into the frying pan, and heat it over medium heat until the oil temperature is At 250°C, use a ladle to scoop the marinated minced meat into the oil along the side of the pot, stir quickly with a frying ladle until a small am...

Embodiment 3

[0052] Ingredients ratio: 490kg tomato paste, 390kg pepper, 90kg minced meat, 13kg scallion, 490kg edible vegetable oil, 4.5kg ginger, 1.5kg salt, 0.2kg monosodium glutamate.

[0053] (1) Preparation of chili sauce: after cleaning and selecting the chili peppers, take the prescribed amount and carry out colloid grinding to obtain chili sauce;

[0054] (2) Oil-fried chili peppers: heat olive oil accounting for 35% of the total amount, control the oil temperature at 110°C, pour in chili sauce and stir-fry until the skin of the chili peppers starts to turn yellow to obtain oily chili sauce;

[0055] (3) Frying of minced meat: first marinate the minced meat with 0.3kg of salt, 0.5kg of rice wine, and 4kg of ginger for 0.5 hours, then add 35% of the total oil into the frying pan, and heat it over medium heat until the oil temperature is At 243°C, use a ladle to scoop the marinated minced meat into the oil along the side of the pot, stir quickly with a frying ladle until a small amo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com