Method of synthesizing Pt-Ni catalyst material by hydrothermal method

A catalyst and a hydrothermal method are applied in the field of hydrothermal synthesis of Pt-Ni catalyst materials with a carbon source as a carrier, which can solve the problems of difficulty in large-scale production, high equipment requirements, high price and the like, and achieves low production cost and high production cost. The effect of small equipment investment and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

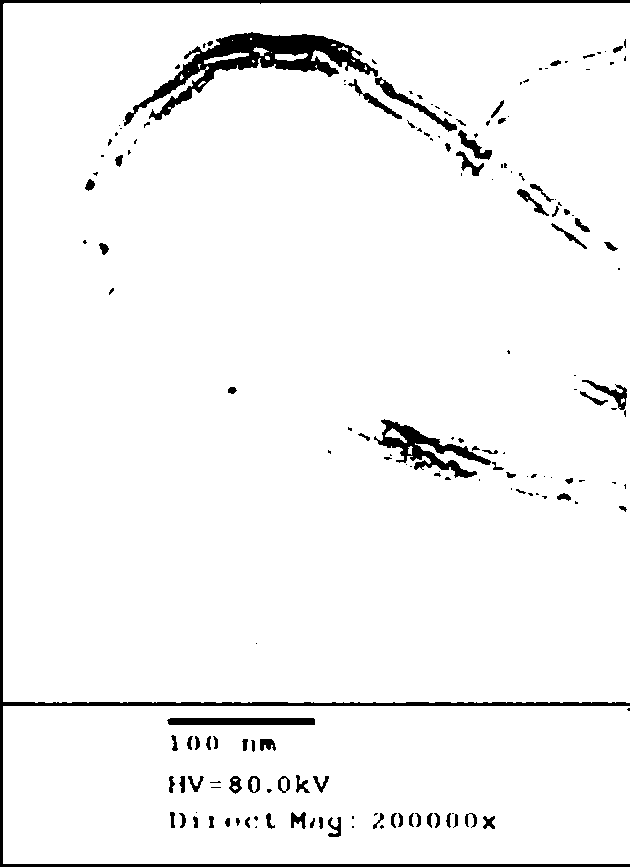

[0023] Take 3mL of 5×10 -3 mol / L H 2 PtCl 6 ·6H 2 O solution and 3 mL of 5 x 10 -3 mol / L Ni(NO 3 ) 2 ·6H 2 O solution (Pt:Ni molar ratio 1:1) was mixed to form a solution. Add 20 mg of multi-walled carbon nanotubes to the solution, ultrasonically disperse for 30 min, transfer the solution to an autoclave with a volume of 50 mL, and heat in a muffle furnace for 2 h at 200 °C (slowly from room temperature to 200 °C). After the liquid was filtered off and washed with secondary water, the precipitate was naturally dried at room temperature and ground to obtain Pt-Ni catalyst nanoparticles attached to multi-walled carbon nanotubes.

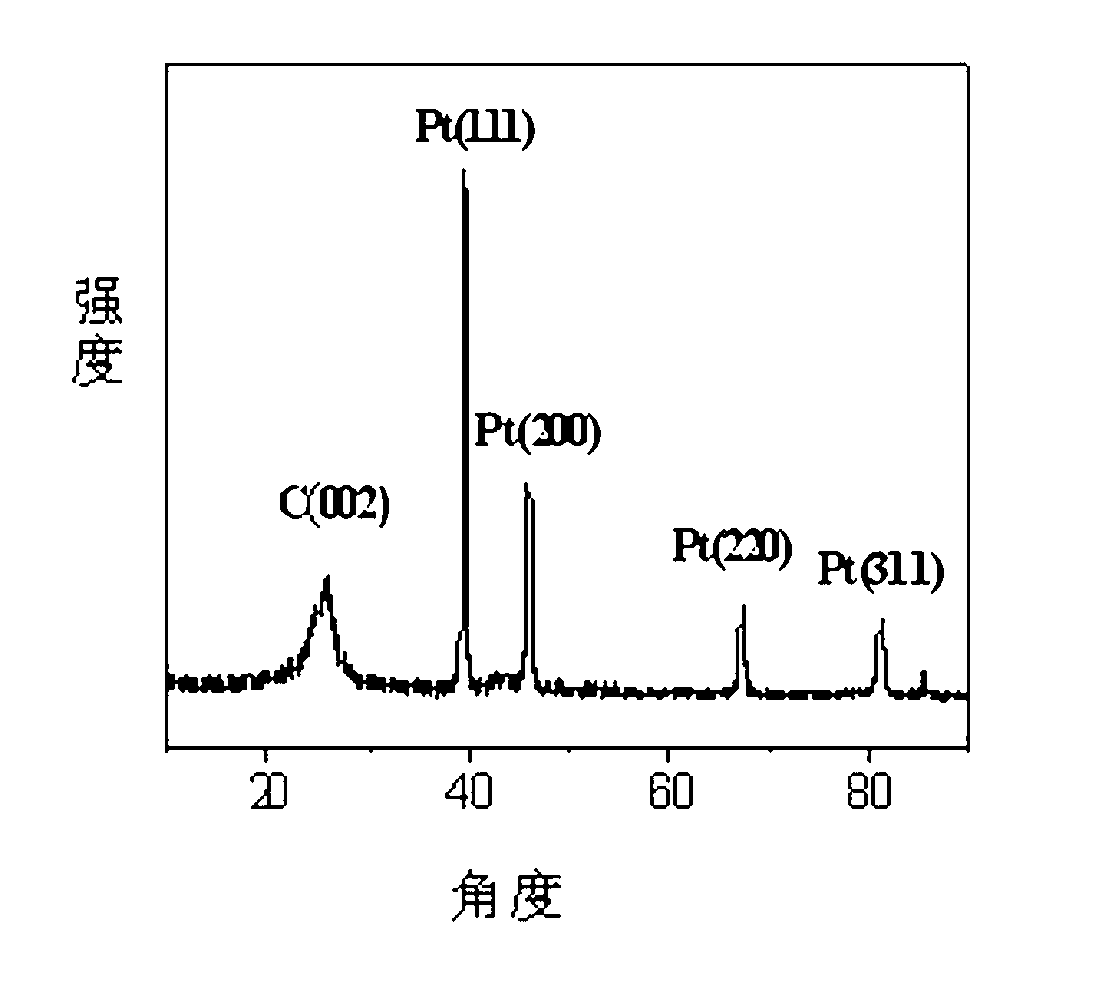

[0024] figure 1 The X-ray diffraction analysis in the above shows that the diffraction peak near 26.24° in the XRD spectrum of the prepared Pt-Ni / MWCNTs catalyst nanoparticles is the diffraction peak of the C (002) crystal plane. The diffraction peaks at 39.834°, 46.387°, 64.655°, and 81.508° correspond to (111), (200), (220), (311) crystals...

Embodiment 2

[0028] Take 3mL of 5×10 -3 mol / L H 2 PtCl 6 ·6H 2 O solution and 6 mL of 5 x 10 -3 mol / L Ni(NO 3 ) 2 ·6H 2 O solution (Pt:Ni molar ratio 1:2) was mixed to form a solution. Add 20 mg of multi-walled carbon nanotubes to the solution, ultrasonically disperse for 30 min, transfer the solution to an autoclave with a volume of 50 mL, and heat in a muffle furnace at 200 °C (slowly warming from room temperature to 250 °C) for 2 h. After filtering off the liquid and rinsing and filtering with secondary water, the precipitate was naturally dried at room temperature, and the Pt-Ni catalyst powder was obtained after grinding.

Embodiment 3

[0030] Take 3mL of 5×10 -3 mol / L H 2 PtCl 6 ·6H 2 O solution and 3 mL of 5 x 10 -3 mol / L Ni(NO 3 ) 2 ·6H 2 O solution (Pt:Ni molar ratio 1:1) was mixed to form a solution. Add 30 mg graphene to the solution, ultrasonically disperse for 30 min, transfer the solution to a 50 mL autoclave, and heat it in a muffle furnace at 200 °C (slowly from room temperature to 200 °C) for 2 h. After filtering off the liquid and rinsing and filtering with secondary water, the precipitate was naturally dried at room temperature, and the graphene-supported Pt-Ni catalyst powder was prepared after grinding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com