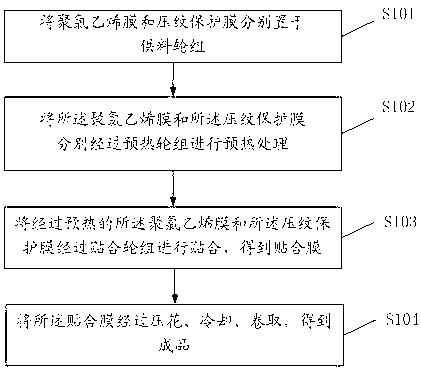

Embossing method for polyvinyl chloride film

A polyvinyl chloride film and embossing technology, which is applied in the field of embossing technology, can solve the problems of reducing gloss, low gloss, and affecting embossing effects, etc., and achieve the effect of protecting gloss, improving gloss and specularity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

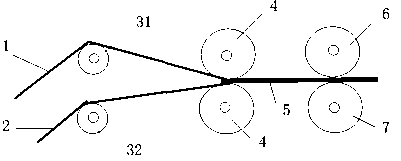

Method used

Image

Examples

Embodiment 1

[0100] A polyvinyl chloride film (referred to as PVC film) with a glossiness of 75 is obtained by calendering molding process, and the PVC film is placed on the first feeding roller group; the polyethylene terephthalate film (referred to as PET film) is placed on the on the second supply roll set. Under the traction of the first feeding wheel set, the PVC film is preheated through the first preheating wheel set at a traction rate of 12m / min, and the preheating temperature is 80°C; under the traction of the second feeding wheel set , the PET film is preheated through the second preheating wheel set at a traction speed of 12m / min. The preheating temperature is 80°C. Laminate the preheated PVC film and PET film through the laminating wheel set at a traction rate of 3 m / min to obtain a laminating film. The laminated film is embossed through an embossing wheel set, then cooled through a cooling wheel set, and finally coiled to obtain a finished product. The thicknesses of the fin...

Embodiment 2

[0102]A polyvinyl chloride film (referred to as PVC film) with a glossiness of 100 was obtained by calendering molding process, and the PVC film was placed on the first feeding roller group; the polyethylene terephthalate film (referred to as PET film) was placed on the on the second supply roll set. Under the traction of the first feeding wheel set, the PVC film is preheated through the first preheating wheel set at a traction rate of 18m / min, and the preheating temperature is 120°C; under the traction of the second feeding wheel set , the PET film is preheated through the second preheating wheel set at a traction speed of 18m / min. The preheating temperature is 120°C. Laminate the preheated PVC film and PET film through the laminating wheel set at a traction rate of 15 m / min to obtain a laminating film. The laminated film is embossed through an embossing wheel set, then cooled through a cooling wheel set, and finally coiled to obtain a finished product. The thicknesses of t...

Embodiment 3

[0104] A polyvinyl chloride film (referred to as PVC film) with a glossiness of 125 was obtained through an extrusion molding process, and the PVC film was placed on the first feeding roller group; the polyimide film was placed on the second feeding roller group. Under the traction of the first feeding wheel set, the PVC film is preheated through the first preheating wheel set at a traction rate of 22m / min, and the preheating temperature is 180°C; under the traction of the second feeding wheel set , the polyimide film is preheated through the second preheating wheel set at a pulling speed of 22 m / min. The preheating temperature is 180°C. Laminate the preheated PVC film and the polyimide film through the laminating wheel set at a traction speed of 25 m / min to obtain a laminating film. The laminated film is embossed through an embossing wheel set, then cooled through a cooling wheel set, and finally coiled to obtain a finished product. The thicknesses of the finished PVC film a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com