Double-air-gap ozone generating device

An ozone generating device and double air gap technology, applied in the field of ozone preparation, can solve the problems of high operating cost, high power consumption of the ozone generator, and low discharge efficiency of the discharge unit, so as to increase the discharge area, increase the ozone concentration and the ozone Effects of productivity, reduction of manufacturing cost and running cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

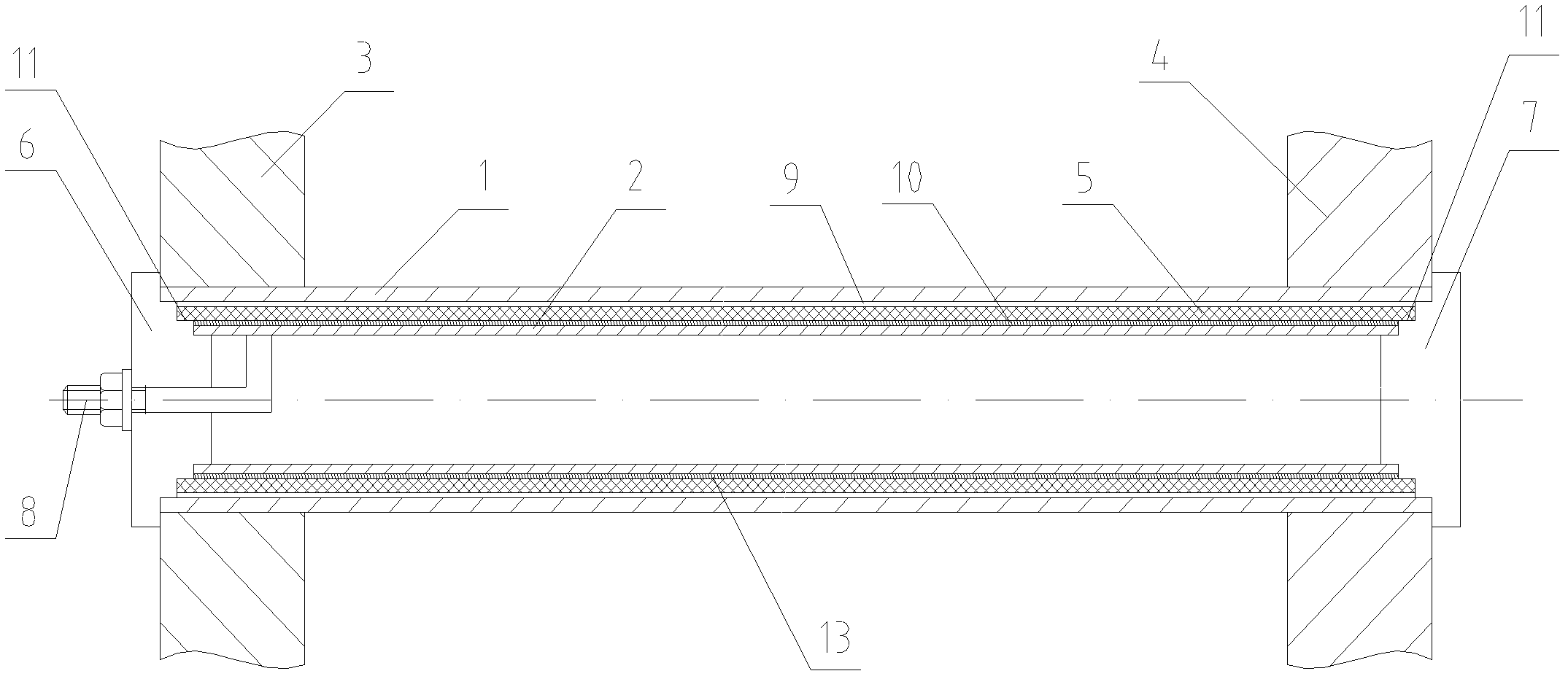

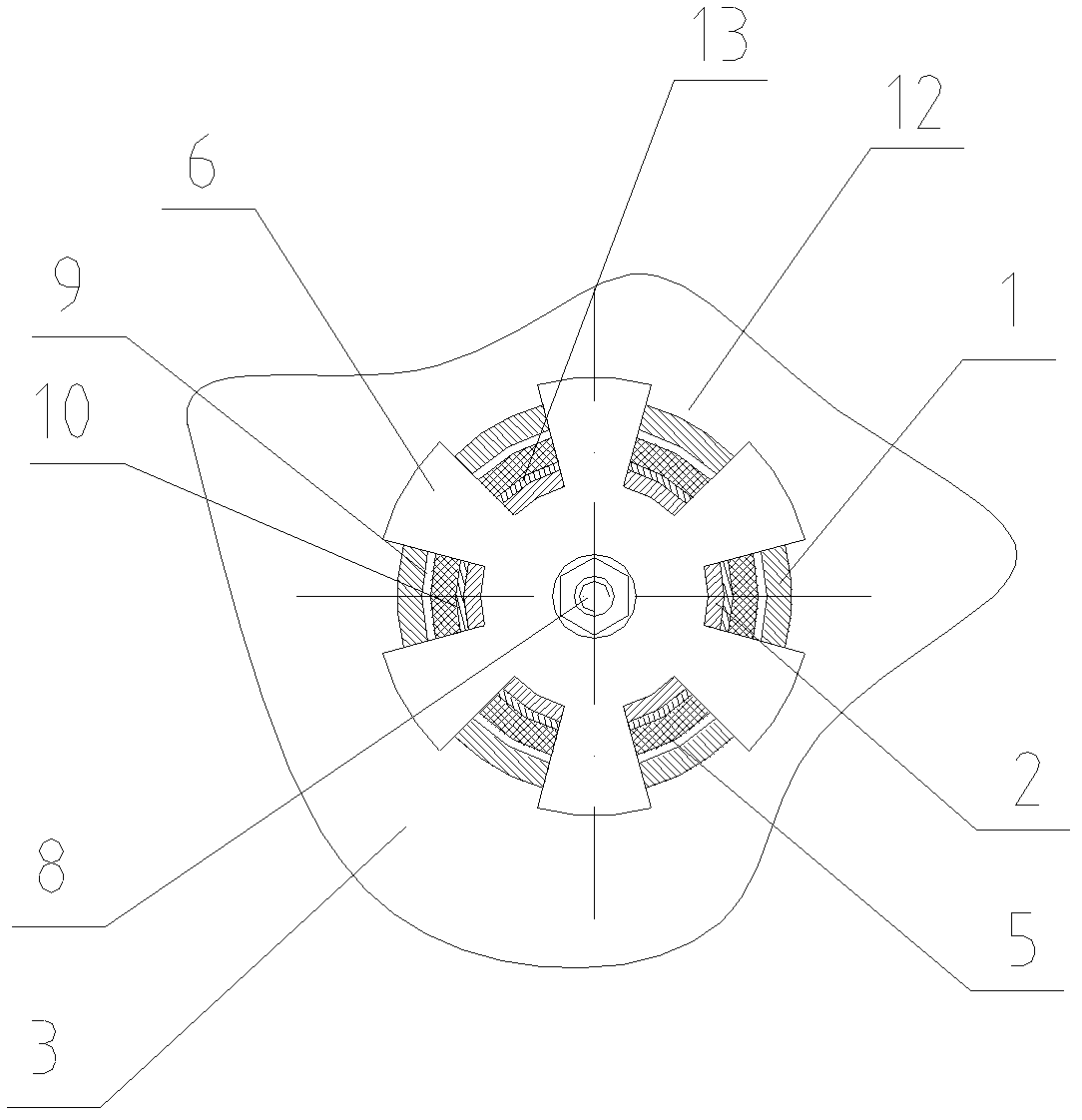

[0010] The present invention will be further described below in conjunction with the accompanying drawings. As shown in the figure, a double-air-gap ozone generator includes a cylindrical outer electrode 1, an inner electrode 2 installed inside the outer electrode 1, and is used to support the outer electrode 1 and conduct electricity. The left flower plate 3 and the right flower plate 4, the glass dielectric tube 5 between the outer electrode 1 and the inner electrode 2, the left end cap 6 and the right end cap 7 for fixing the inner and outer electrodes 1, 2 and the glass dielectric tube 5 , the electrode 8 connected to the inner electrode 2 through the left end cover 6, the gap between the outer electrode 1 and the glass dielectric tube 5 is the outer air gap 9, and the gap between the glass dielectric tube 5 and the inner electrode 2 is the inner air The left and right end caps 6, 7 are provided with three limiting steps 11 on opposite sides, and the left and right end caps...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com