Non-woven fabrics containing carboxymethyl cellulose fibers and purpose thereof in beauty mask substrate

A technology of carboxymethyl cellulose and chitin fiber, which is applied in the directions of non-woven fabrics, textiles and papermaking, and cosmetic preparations, etc., to achieve the effects of high hygroscopicity, high moisture retention, and good oxygen permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] CMC non-woven fabric

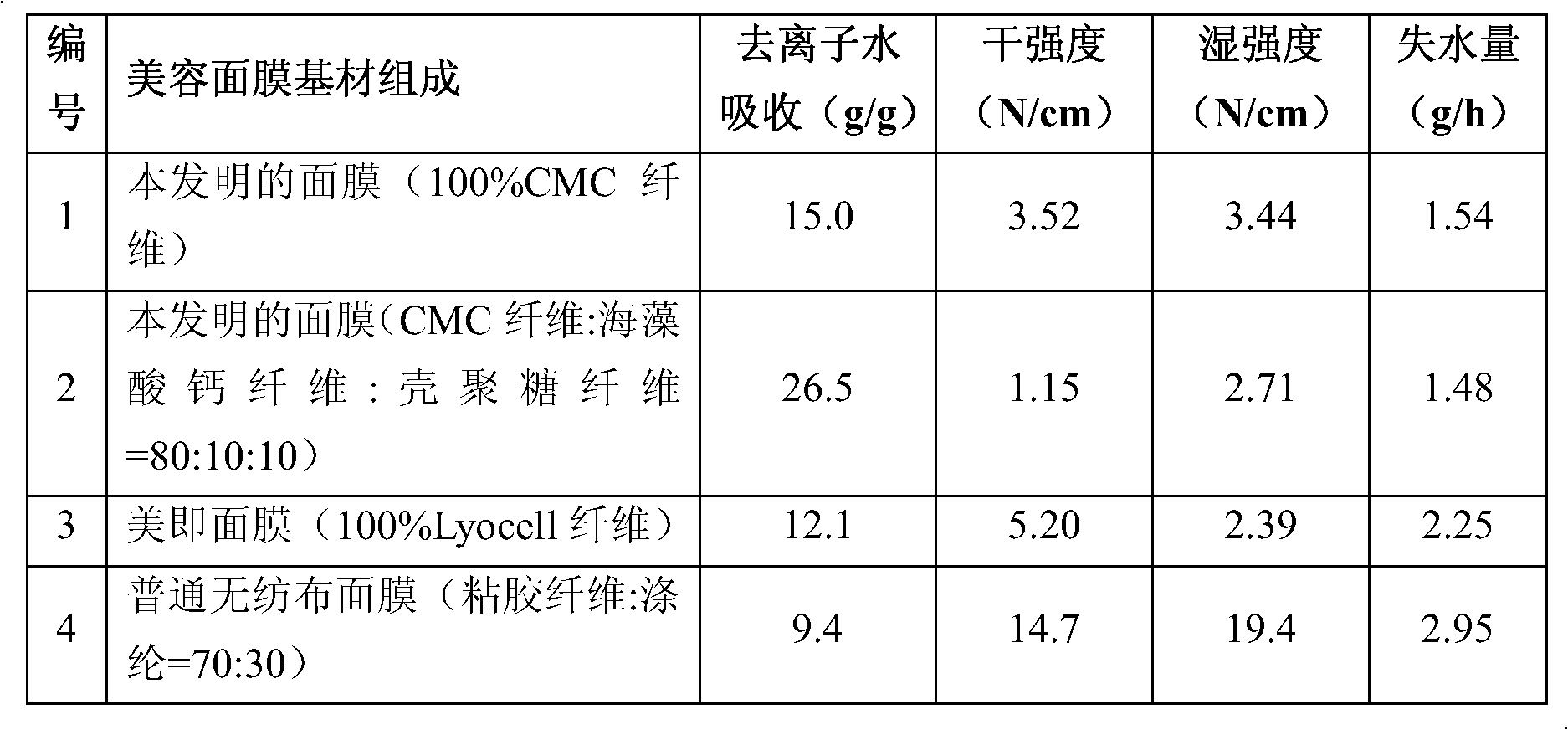

[0024] Feed viscose fiber to prepare viscose fiber non-woven fabric, and then undergo carboxymethylation reaction to obtain CMC non-woven fabric. The non-woven fabric has a deionized water absorption of 15.0g / g, a dry strength of 3.52N / cm, and a wet strength of 3.44N / cm. The material is thin and air-permeable.

Embodiment 2

[0026] CMC, calcium alginate fiber blended non-woven fabric

[0027] CMC fibers: calcium alginate fibers are mixed at a mass ratio of 90:10 and fed, and then CMC and calcium alginate blended non-woven fabrics are prepared. The non-woven fabric has a deionized water absorption of 20.5g / g, a dry strength of 3.46N / cm, and a wet strength of 5.02N / cm. The material is thin and air-permeable.

Embodiment 3

[0029] CMC, chitin fiber blended non-woven fabric

[0030] The CMC fiber: chitin fiber is mixed at a mass ratio of 95:5 and fed, and then the CMC and chitin blended non-woven fabric is prepared. The non-woven fabric has a deionized water absorption of 19.4g / g, a dry strength of 3.75N / cm, and a wet strength of 1.52N / cm. The material is thin and air-permeable.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Linear density | aaaaa | aaaaa |

| Hygroscopicity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com