A design method of two-way pressure-spin uplift piles

A design method and technology of uplift piles, applied in sheet pile walls, buildings, foundation structure engineering, etc., can solve the problems of high equipment capacity requirements for static pressure piles, time-consuming and equipment-consuming bored piles, and other pile pullout performance Unsatisfactory problems, to achieve the effect of improving the bearing function, simplifying the construction method, and eliminating the piling noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing, introduce the two-way static pressure rotation uplift pile of the present invention.

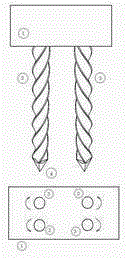

[0033] figure 1 Shown is the structural diagram of the two-way rotating pile foundation of the present invention, which is arranged symmetrically on the cap. When loading, due to the reaction force of the foundation soil, the moment generated by the pile is self-balanced under the constraints of the cap.

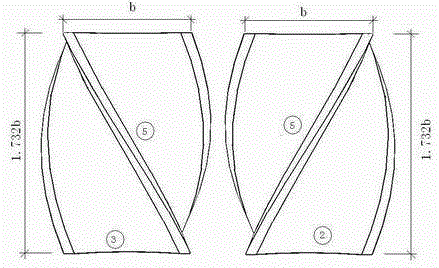

[0034] The clockwise rotating pile ② and the counterclockwise rotating pile ③ are symmetrically arranged, and their upper ends are fixedly connected with the pile cap ①. The pile point ④ is connected with the pile body ②, ③ at the lower end of the pile. ⑤ is the external curve ductile angle after the rotation of ② and ③ pile body.

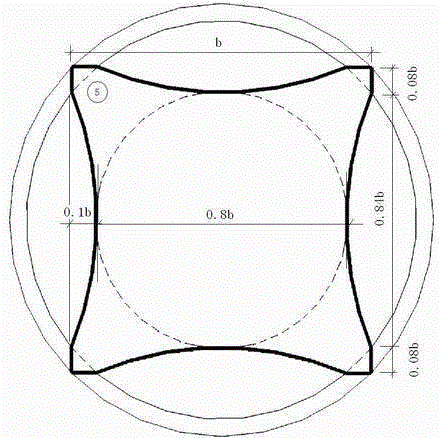

[0035] figure 2 It is the horizontal profile of the pile. According to the actual length L of the pile, the circumscribed circle is within the length of one unit, forming a space inclined surface. The a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com