Tubular pile structure bound by steel-cement soil bodies and construction method of the tubular pile structure

A construction method, cement-soil technology, applied in foundation structure engineering, sheet pile walls, buildings, etc., can solve the problems of poor consolidation force, poor stability, large settlement, etc., achieve good protection effect, small environmental impact, and construction The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

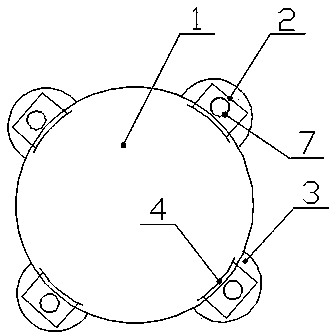

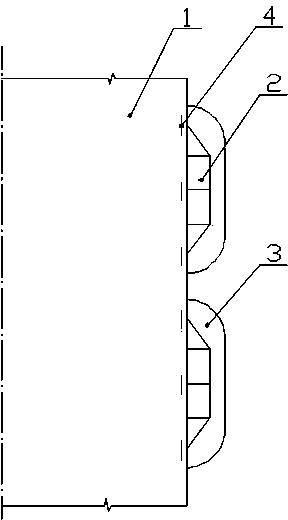

[0025] see figure 1 with figure 2 , the steel-cement soil binding pipe pile structure of the present invention, the pipe pile structure includes prestressed pipe piles, and the outer wall of the prestressed pipe pile 1 is welded with at least two longitudinal steel structure frames 2 along the radial direction , The cement soil body 3 is poured on the longitudinal steel structure frame 2 .

[0026] The cross-section of the above-mentioned longitudinal steel structure frame 2 is "ㄇ" type.

[0027] The above-mentioned longitudinal steel structure frame 2 is distributed in sections on the outer wall of the prestressed pipe pile.

[0028] The upper and lower parts of the above-mentioned longitudinal steel structure frame 2 are provided with a triangular reinforced frame structure 5 .

[0029] The middle part of the longitudinal steel structure frame 2 is provided with a triangular reinforced frame structure 6 .

Embodiment 2

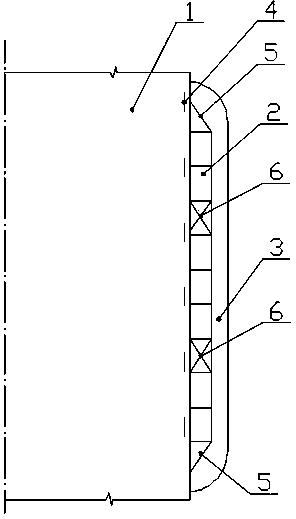

[0031] see figure 1 with image 3 , the steel-cement soil binding pipe pile structure of the present invention, the pipe pile structure includes prestressed pipe piles, and the outer wall of the prestressed pipe pile 1 is welded with at least two longitudinal steel structure frames 2 along the radial direction , The cement soil body 3 is poured on the longitudinal steel structure frame 2 .

[0032] The cross-section of the above-mentioned longitudinal steel structure frame 2 is "ㄇ" type.

[0033] The above-mentioned longitudinal steel structure frame 2 is integrally distributed on the outer wall of the prestressed pipe pile.

[0034] The upper and lower parts of the above-mentioned longitudinal steel structure frame 2 are provided with a triangular reinforced frame structure 5 .

[0035] The middle part of the longitudinal steel structure frame 2 is provided with a triangular reinforced frame structure 6 .

[0036] The construction method of above-mentioned two embodiments...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com