A large turbocharged two-stroke diesel engine with exhaust gas purification

A diesel engine, turbocharging technology, applied in engine components, combustion engines, machines/engines, etc., can solve the problems of efficiency loss, fuel efficiency, complicated use, limited applicability of power turbines, etc., and achieve simple injection and supply systems. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

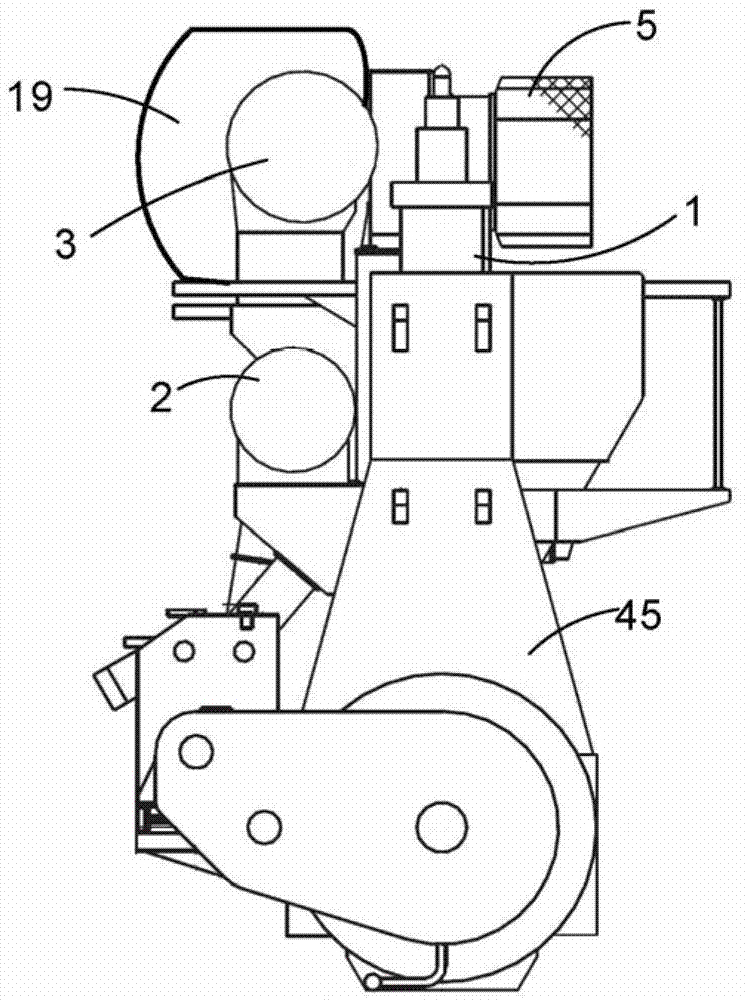

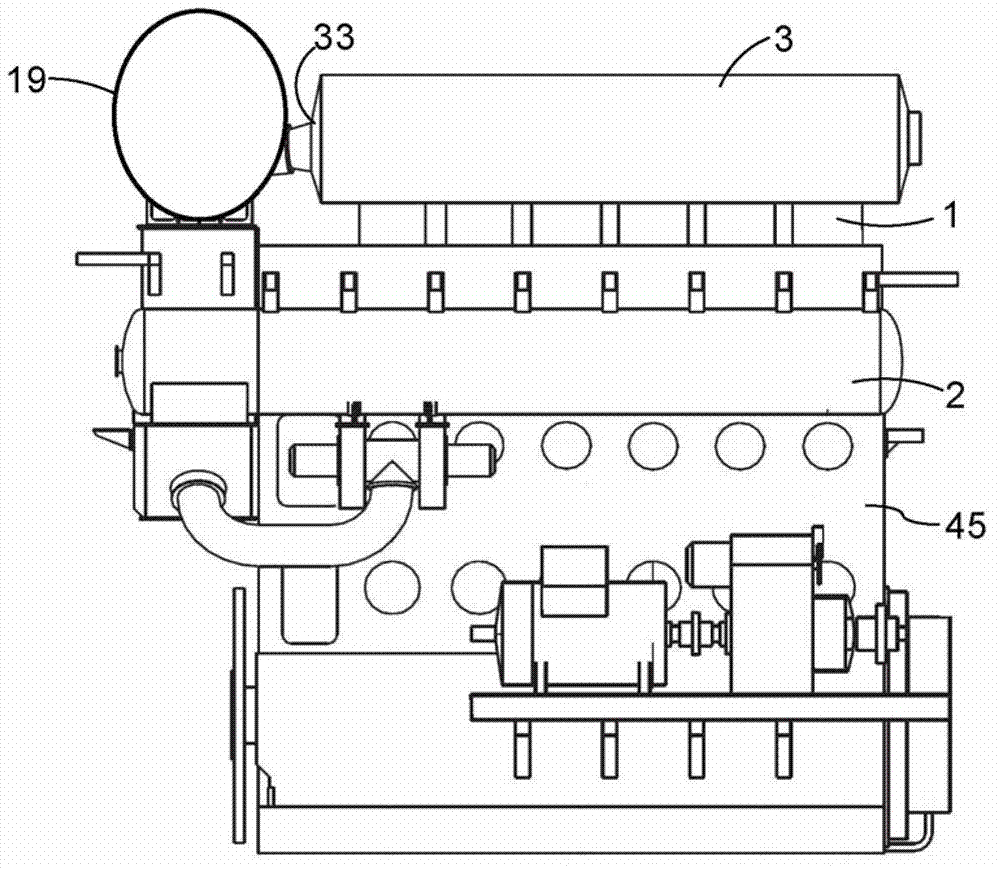

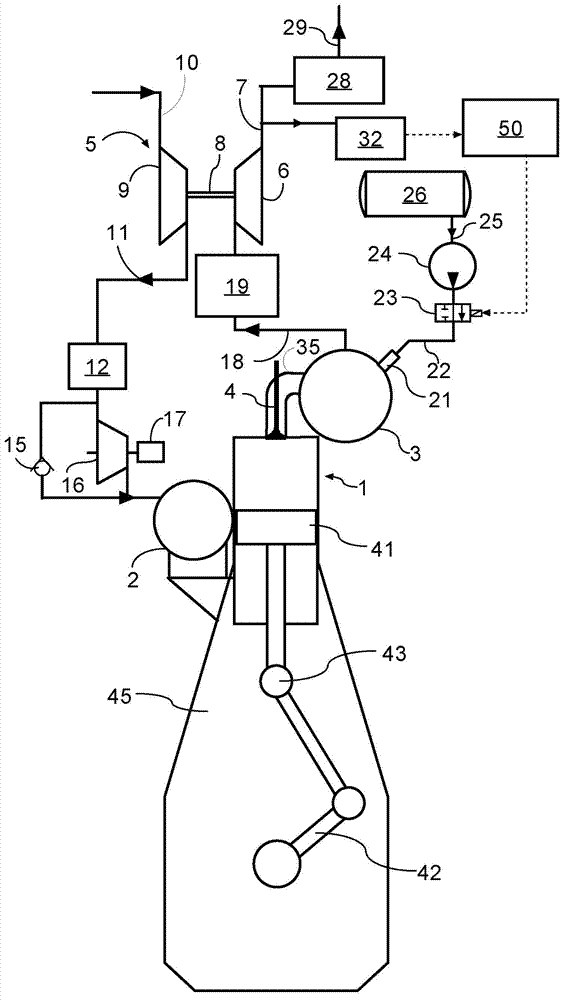

[0042] In the following detailed description, a large two-stroke engine will be described by way of exemplary embodiments. Figure 1 to Figure 3 A large low speed turbocharged two stroke diesel engine with crankshaft 42 and crosshead 43 is shown. image 3 A diagrammatic representation of a large low-speed turbocharged two-stroke diesel engine with induction and exhaust systems is shown. In this exemplary embodiment, the engine has six in-line cylinders 1 . Large turbocharged two-stroke diesel engines typically have five to sixteen in-line cylinders carried by the engine frame 45 . The engine can be used, for example, as the main engine of an ocean-going vessel or as a stationary engine running an electric machine in a power station. The total output of the engine may for example be from 5,000 kW to 110,000 kW.

[0043] The engine is a two-stroke single-flow engine with scavenging ports in the bottom area of cylinder 1 and exhaust valve 4 at the top of cylinder 1 . The ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com