Power-off protection mechanism of magnetic suspension rotor support system

A magnetic levitation rotor and support system technology, applied in the direction of electrical components, electromechanical devices, mechanical equipment, etc., can solve the problems of high-speed rotor dynamic balance damage, reduce the service life of the rotor shaft, mechanical damage, etc., and achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

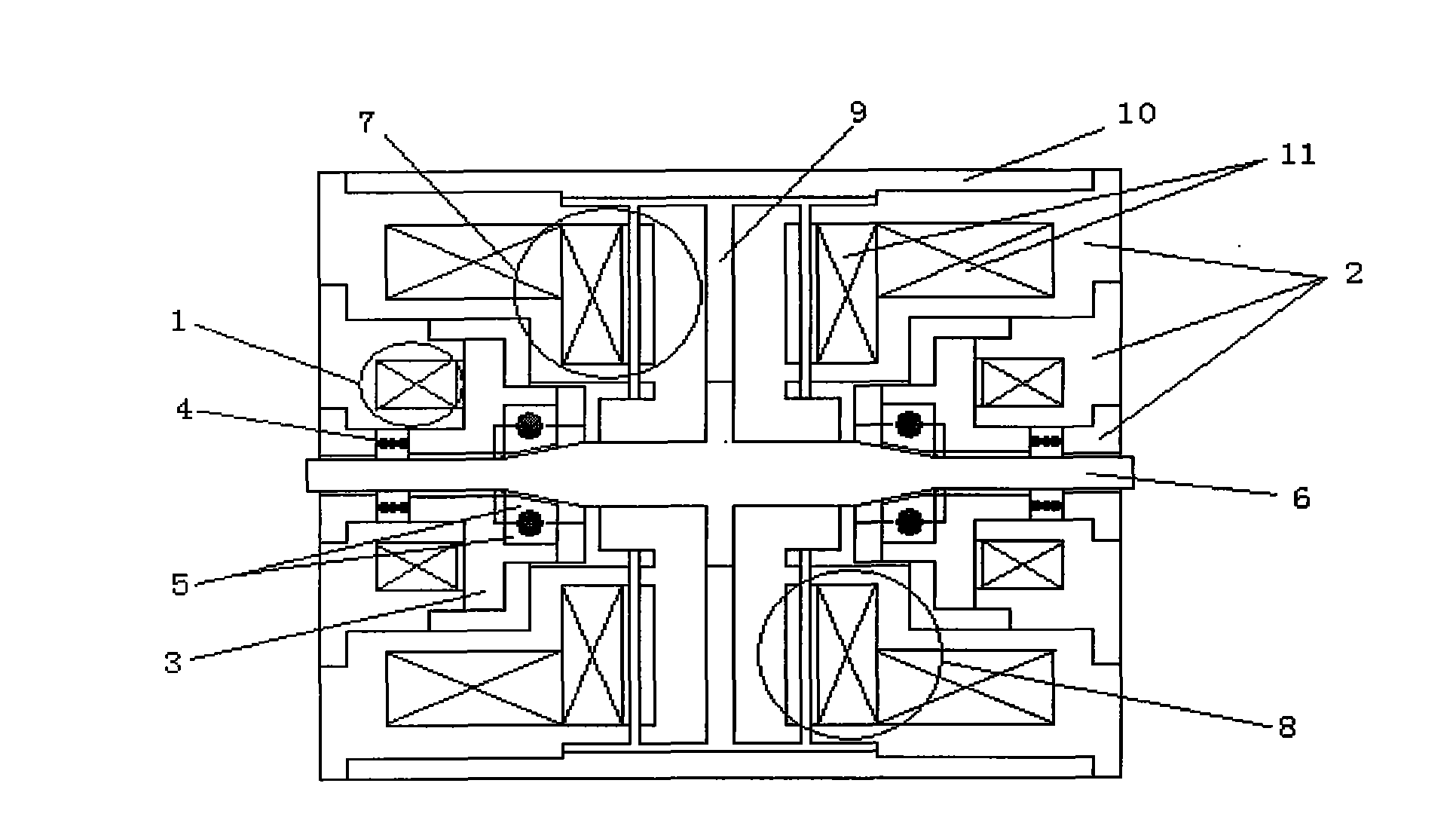

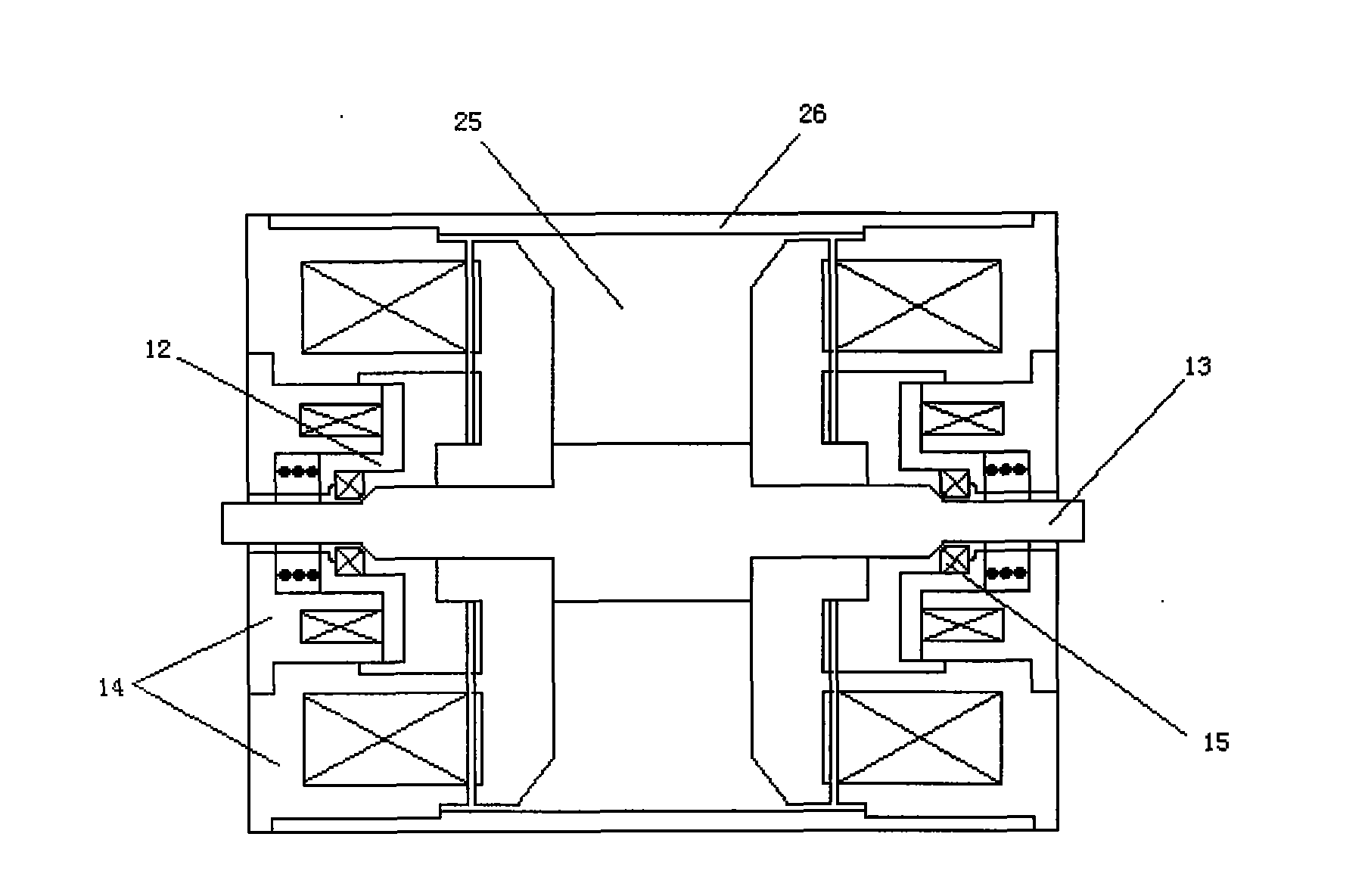

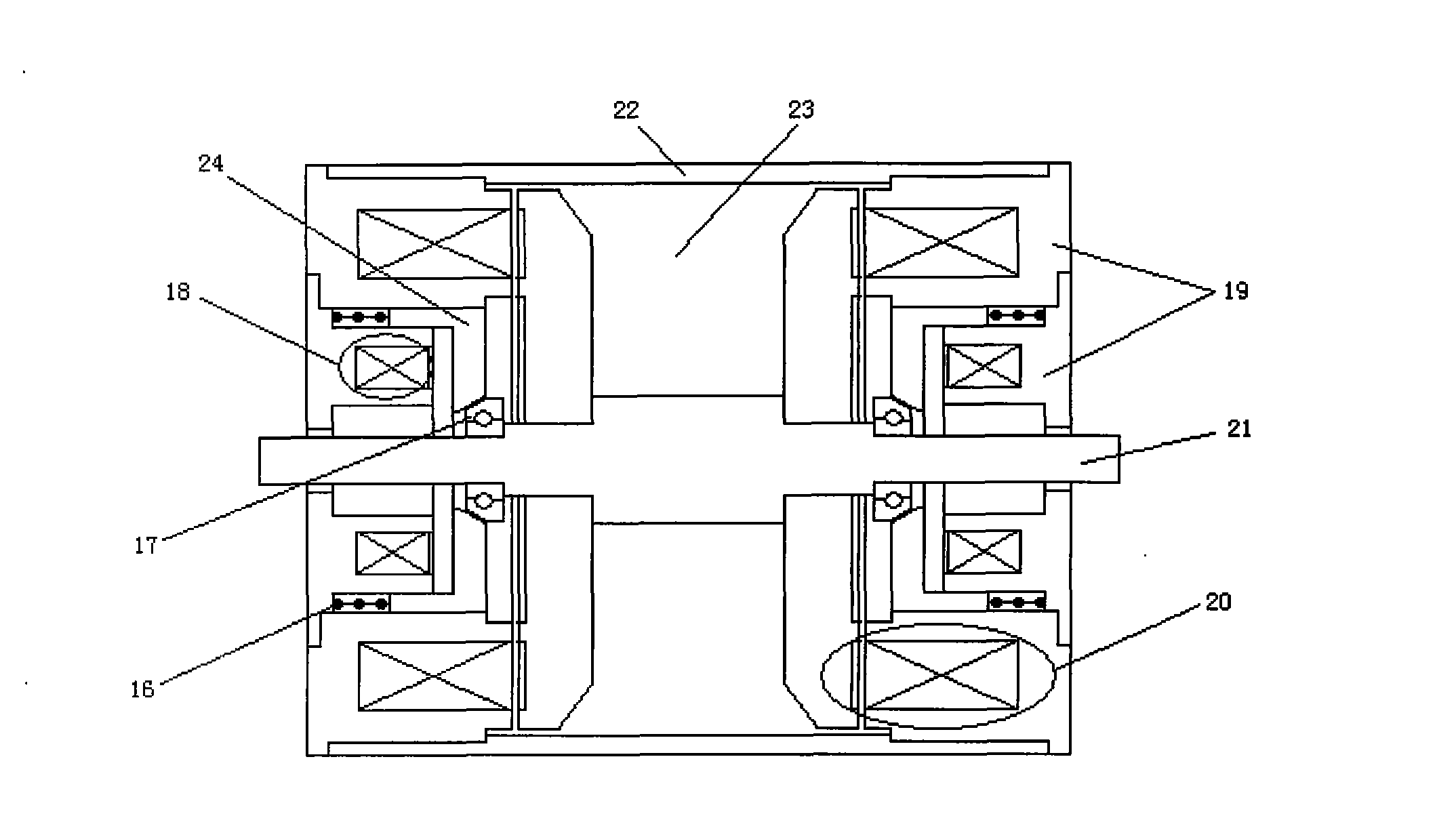

[0017] The power-off protection mechanism of the magnetic levitation rotor support system of the present invention will be further described in detail with specific implementation methods and accompanying drawings:

[0018] according to figure 1 The power-off protection mechanism of the magnetic levitation rotor support system of the present invention is shown, which is composed of two electromagnets 1 that generate axial attraction force and one that can form an axial direction with the radial wall of the stator part 2 of the magnetic levitation rotor support system. Rotor shaft support composed of slidably fitted bearing sleeve 3, axial thrust spring 4 between the bearing sleeve and the axially opposite surface of the stator part, and mechanical bearing 5 seated on the bearing sleeve The switcher is opposed and sleeved on the periphery of the proximal end of the rotor shaft 6, and then the electromagnetically attracted radial magnetic suspension bearings 7 and 8 with an axia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com