Automatic assembly control system for storage battery pole group

A technology of automatic assembly and control system, applied in the direction of lead-acid battery, electrical program control, lead-acid battery construction, etc., can solve the problems of mechanization and low level of automation, and achieve convenient equipment installation, debugging and maintenance, convenient station expansion, The effect of improving assembly production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

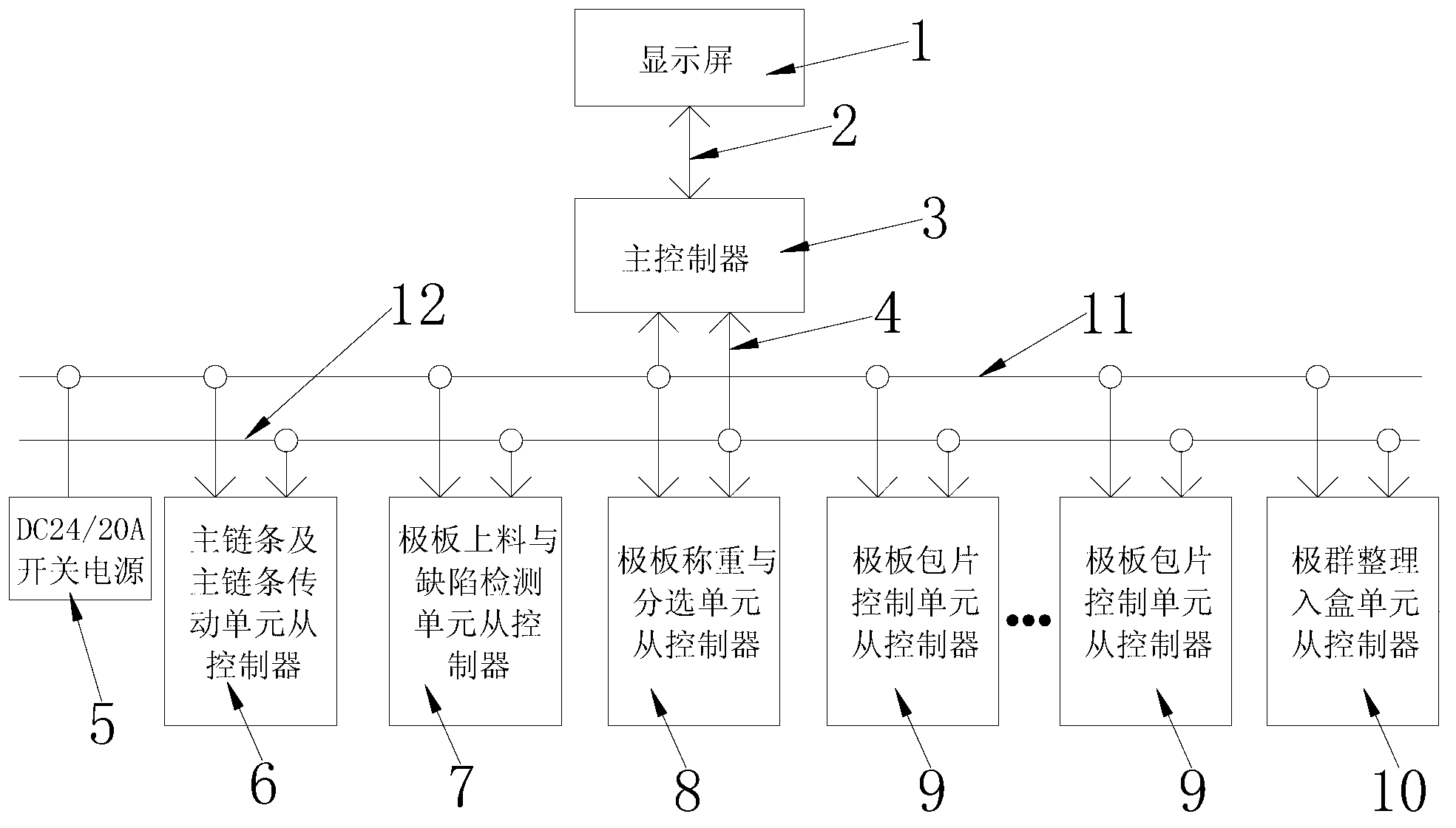

[0016] refer to figure 1 , the battery pole group automatic assembly control system of the present invention includes a display screen 1, RS485 data lines 2, a master controller 3, several CAN data lines 4, switching power supplies 5, several slave controllers and several power lines, and the display screen 1 It is connected with the main controller 3 through the RS485 data line 2, and the main controller 3 is connected with each slave controller through the CAN data line 4. The RS485 communication is adopted between the display screen 1 and the main controller 3, and the main control CANBUS communication is adopted between the controller 3 and each slave controller, and the power line includes a first power line 11 and a second power line 12, and the first power line 11 and the second power line 12 are connected with the main controller 3 and each slave The controller is connected, the switching power supply 5 is connected to the first power line 11, and there are 12 slave co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com