Manufacturing method of precision alloy sampling resistor

A technology of sampling resistors and precision alloys, applied in resistors, resistor manufacturing, circuits, etc., can solve the development trend that cannot meet the miniaturization and environmental protection of instruments, the waste of dust and chemical pollution of raw materials, and the inability to flexibly change the shape of the terminal, etc. problems, to achieve the effect of increasing reliability and high temperature resistance of welds, improving efficiency, and small diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention is further described below in conjunction with embodiment and accompanying drawing.

[0012] This embodiment includes the following steps:

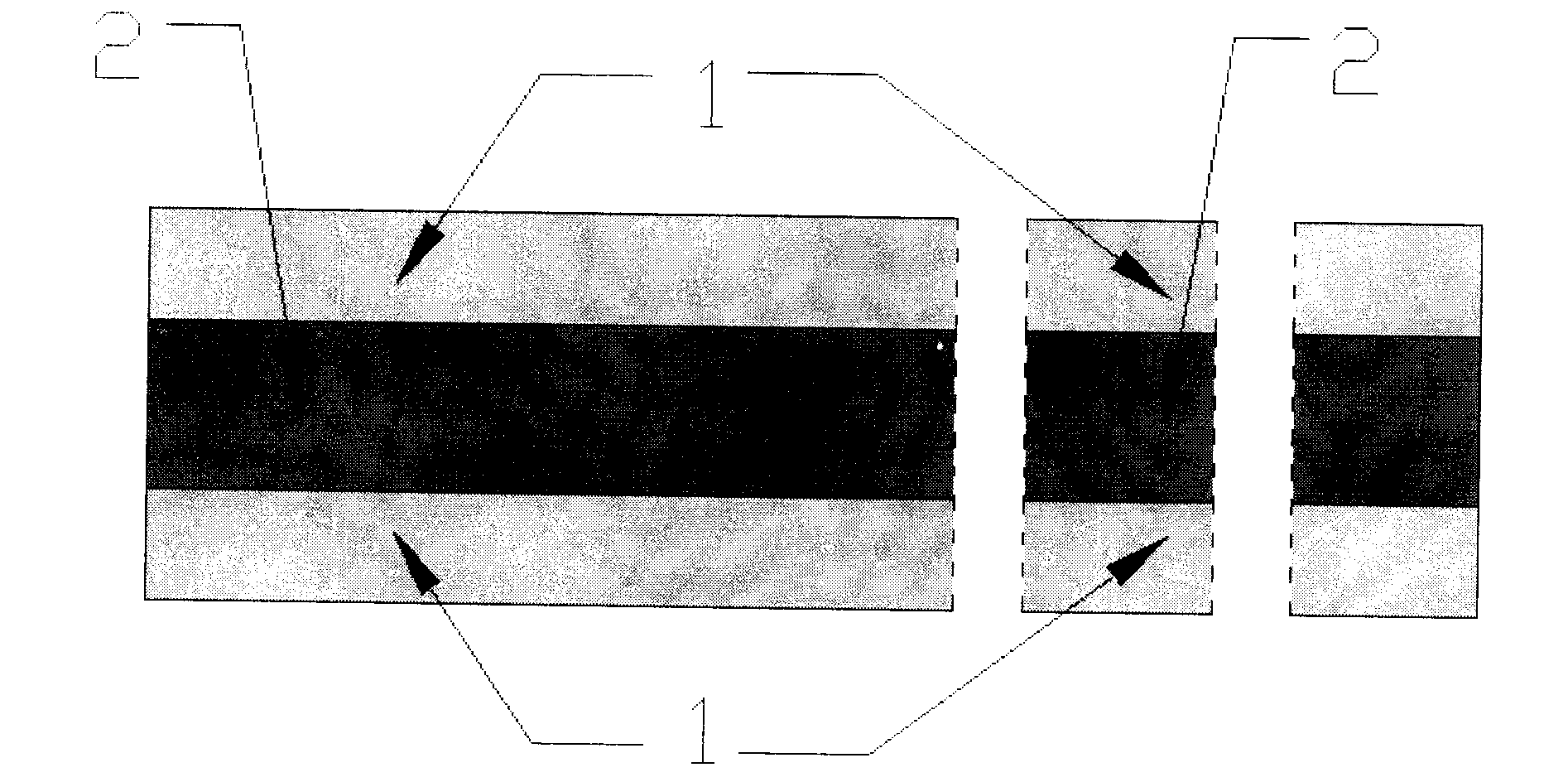

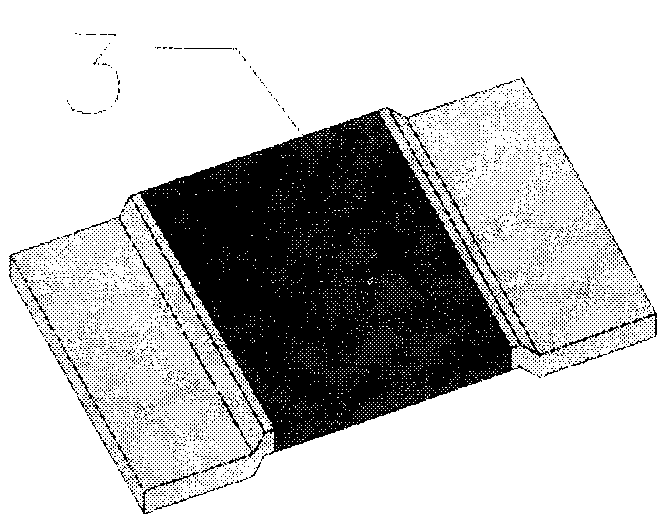

[0013] 1. See figure 1 , take a manganese-copper alloy strip 2 with a material composition of Cu87%, Mn12%, Ni balance, a thickness of 1.5mm, and a width of 6mm. The manganese-copper alloy strip 2 is a resistor material. Two thicknesses of 1.5 mm, the oxygen-free copper strip 1 with a width of 5mm, the oxygen-free copper strip 1 is the electrode material, and the two oxygen-free copper strips 1 are respectively attached to the two sides of the manganese-copper alloy strip 2, and are clamped with a clamping device. After the three are clamped and fixed, they are cleaned;

[0014] 2. Put the three strips fixed together into the welding chamber of the vacuum electron beam welding equipment, and adjust the operating parameters of the electron beam welding equipment to make the vacuum degree 2.0×10 -3 pa, focus ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com