Thin film transistor (TFT) array substrate and manufacture method and display device thereof

A technology of an array substrate and a manufacturing method, applied in the display field, can solve the problems of large exposure, damage to the active layer, increase in the manufacturing cost of the array substrate, etc., and achieve the effects of reducing costs, ensuring characteristics, and overcoming damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

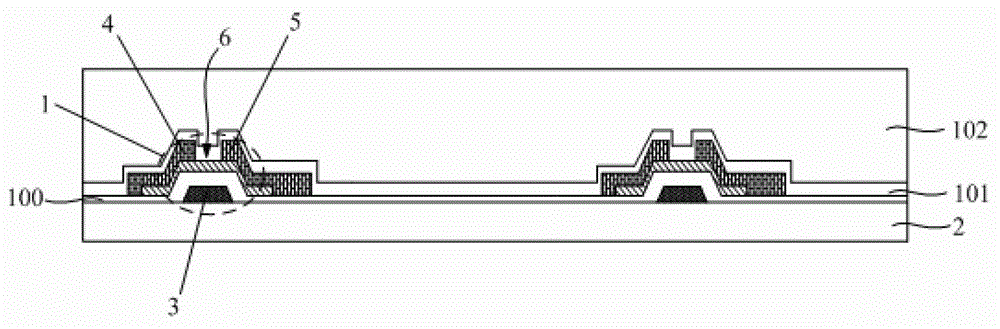

[0038] combine Figure 1-Figure 8 As shown, the manufacturing method of the TFT array substrate in the embodiment of the present invention includes:

[0039] S1. Forming a thin film transistor on a substrate;

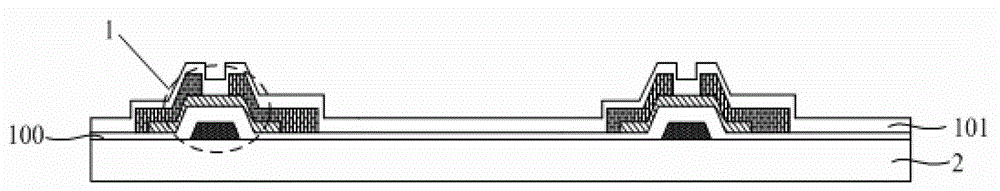

[0040] combine figure 1 As shown, a thin film transistor 1 is first formed on a base substrate 2 . Wherein, the base substrate 2 is made of a light-transmitting material with good light-transmitting properties, and is usually a glass substrate, a quartz substrate or a transparent resin substrate.

[0041] In one embodiment, forming the thin film transistor 1 on the base substrate 2 specifically includes: combining Figure 9 As shown, gate lines 20 and data lines 30 distributed horizontally and vertically are formed on the substrate 2, wherein the area defined by the crossing of gate lines 20 and data lines 30 is the pixel unit area 40, and the thin film transistor 1 is formed in the pixel unit area. In the region 40 , specifically, the thin film transistor 1 may be ...

Embodiment 2

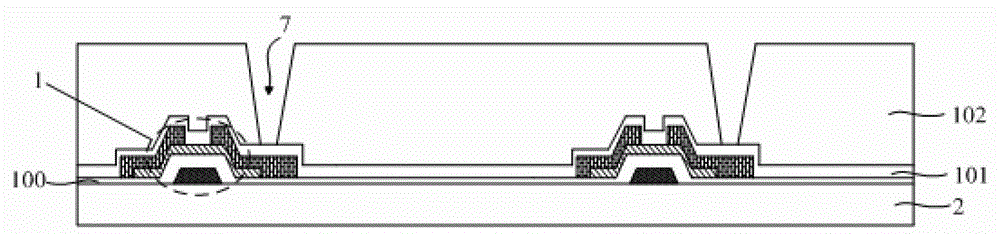

[0078] In this embodiment, an array substrate is provided, combined with Figure 8 and Figure 9 As shown, the array substrate includes a thin film transistor 1 formed on a base substrate 2 , a color filter 10 and a pixel electrode 9 , wherein the color filter 10 corresponds to the area where the pixel electrode 9 is located. The array substrate also includes a light-shielding sheet 8 formed on the top of the thin film transistor 1, and an opaque conductive metal layer film 103 of the same material as the light-shielding sheet 8 is provided above the passivation layer via hole 7, and the pixel electrode 9 passes through the opaque conductive metal layer. The thin film 103 is electrically connected to the drain electrode of the thin film transistor 1 . The setting of the light shield 8 can prevent the active layer of the thin film transistor 1 from being damaged due to excessive exposure in the patterning process, so as not to affect the characteristics of the thin film transi...

Embodiment 3

[0080] This embodiment provides a display device. The display device adopts the array substrate in Embodiment 2, forms the passivation layer via hole pattern through only one patterning process, and forms a The pattern of the light-shielding film, because the array substrate overcomes the damage to the active layer of the thin film transistor due to excessive exposure in the patterning process, thus will not affect the characteristics of the thin film transistor, and greatly reduces the cost of forming color filters on the array substrate. The cost is reduced, and the display quality of the display device is improved.

[0081]It can be seen from the above examples that the TFT array substrate and its manufacturing method and display device provided by the present invention form the passivation layer via hole pattern only through one patterning process, and then in the photoresist stripping process of the patterning process The pattern of the light-shielding sheet is formed, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com