Smoke-dried cheese sausage and preparation method thereof

A cheese and smoking technology, applied in the field of smoked cheese sausage and its preparation, can solve problems such as unpleasant enema smoking, and achieve the effects of easy operation, feasible production process and high nutritional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

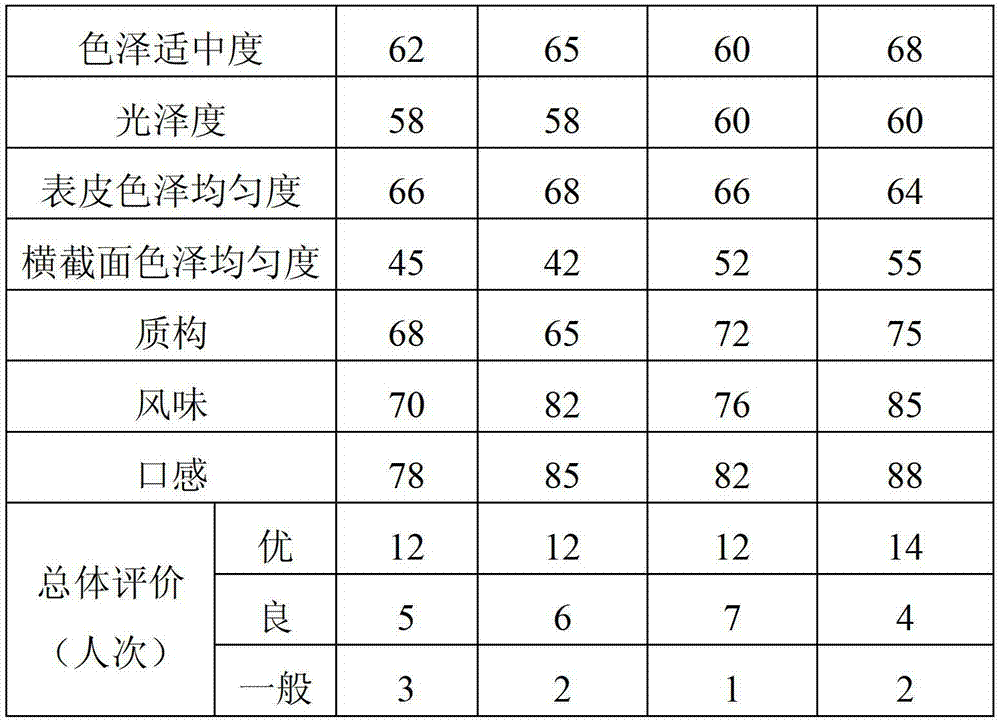

Examples

Embodiment 1

[0040] A preparation method for smoked cheese sausage, comprising the steps of:

[0041] (1) Add lactic acid bacteria starter LL-50 and rennet Fromase 750XLG to the whole milk to make the whole milk curd, cut into curds with a size of 10mm cubes, drain the whey and turn it over for brewing, add 2‰ Edible salt of whole milk quality to get curd grains;

[0042] (2) Put curd grains into molds, pre-press in cheese molds at 10°C with a pressure of 4 MPa for 15 minutes, turn over and repeat the previous pre-pressing once, demould after pre-pressing, and gently break up and demould The final material is enema with a sausage enema machine, and a cheese sausage with a diameter of 45mm and a single weight of 250g is obtained by using a collagen casing. Press the cheese sausage in a cheese mold at a pressure of 3 MPa for 8 hours at a pressing temperature of 10°C, and turn the cheese sausage every 2 hours during the pressing process;

[0043] (3) Dry the surface of the cheese sausage with...

Embodiment 2

[0046] A preparation method for smoked cheese sausage, comprising the steps of:

[0047] (1) Add lactic acid bacteria starter R707 and rennet to skim milk Calf rennet to make skim milk curd, cut into clots with a size of 8mm cubes, drain whey naturally, add water to rinse and drain the water, add 1.5‰ skim milk quality edible salt to obtain curd grains;

[0048] (2) Put curd grains into molds, pre-press in cheese molds at 15°C with a pressure of 6 MPa for 10 minutes, turn over and repeat the above-mentioned pre-pressing twice, demould after pre-pressing, lightly break up and take off The molded material is enema with a sausage enema machine, using a cellulose casing to obtain a cheese sausage with a diameter of 28mm and a single weight of 80g; after using a needle board to poke holes in the flat cheese sausage to remove the gas inside the cheese sausage, Then press the cheese sausage in a cheese mold with a pressure of 2 MPa for 10 hours, the pressing temperature is 5°C, and...

Embodiment 3

[0052] A preparation method for smoked cheese sausage, comprising the steps of:

[0053] (1) Add lactic acid bacteria starter MM100 and rennet to whole goat milk Calf rennet is used to make full-fat goat milk curd, cut into clots with a size of 15mm cubes, drain the whey, add 2‰ full-fat goat milk quality edible salt, and obtain curd grains;

[0054] (2) Put curd grains into molds, pre-press in cheese molds at 20°C with a pressure of 5 MPa for 10 minutes, turn over and repeat the previous pre-pressing once, demould after pre-pressing, and gently break up and demould The final material is enema with a sausage enema machine, and a cheese sausage with a diameter of 40 mm and a single weight of 220 g is obtained by using a collagen casing; Press the cheese sausage in a cheese mold at a pressure of 2 MPa for 12 hours at a pressing temperature of 4°C, and turn the cheese sausage every 1.5 hours during the pressing process;

[0055] (3) Dry the surface of the cheese sausage with c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com