Rotational flow strengthening method and device for purifying sulfur production tail gases by Claus method

A Claus method and tail gas purification technology, which is applied in the field of Claus method sulfur production tail gas purification, high-efficiency desulfurization and sulfur production tail gas containing sulfur element and sulfide, which can solve the problem of small investment, general effect of sulfur-containing compounds, and inability to achieve World leading level indicators and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

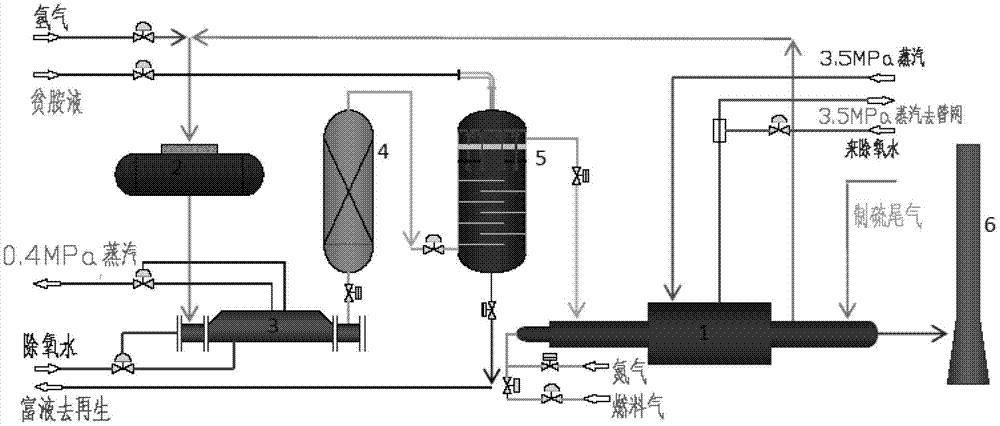

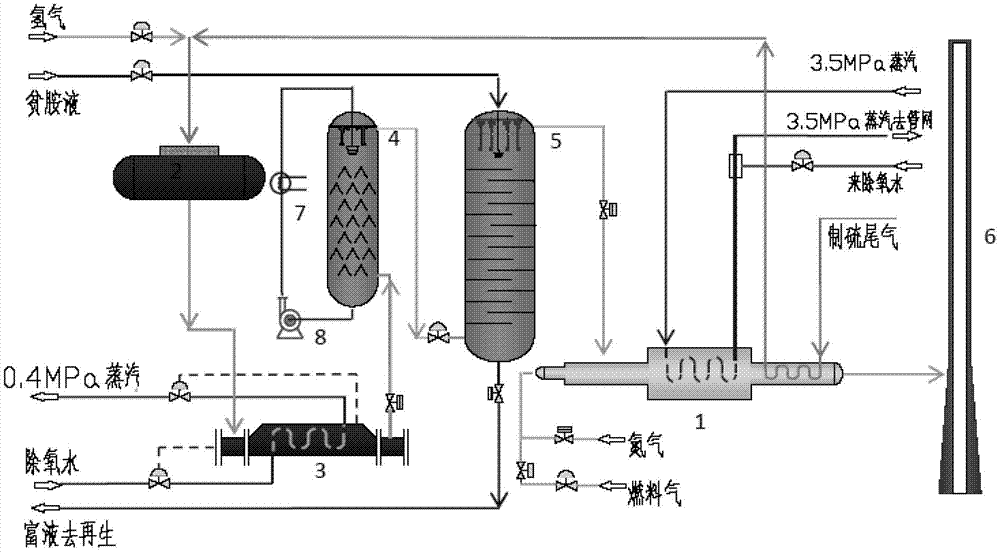

Image

Examples

Embodiment 1

[0085] In a 40,000-ton / year sulfur recovery device, according to the swirl enhancement method and device for purification of sulfur tail gas produced by the Claus method of the present invention, the sulfur-containing tail gas is strengthened and separated to achieve high efficiency, high precision, and low loss. Complete the effective absorption and separation of sulfur compounds in sulfur tail gas, so that the concentration of sulfur dioxide emission in the tail gas reaches the world level (the concentration of sulfur dioxide emission is lower than 200mg / Nm 3 ). Its specific operation process and effect are described as follows:

[0086] 1. Properties and operating conditions of sulfur tail gas

[0087] The tail gas to be treated is mainly the tail gas discharged from the sulfur production part of the conventional Claus process using one-stage high-temperature conversion and two-stage catalytic conversion. The main components are: the main components in the acid gas are H ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com