High-pressure water jet sand-blast cleaning production line for inner surface of tubing

A high-pressure water jet and sandblasting cleaning technology, which is applied in the direction of spray guns, explosion generating devices, abrasive jetting machine tools, etc., can solve the problems of unstable cleaning quality, low sand concentration, and low cleaning efficiency, and shorten the distance of sand conveying , good cleaning effect, simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

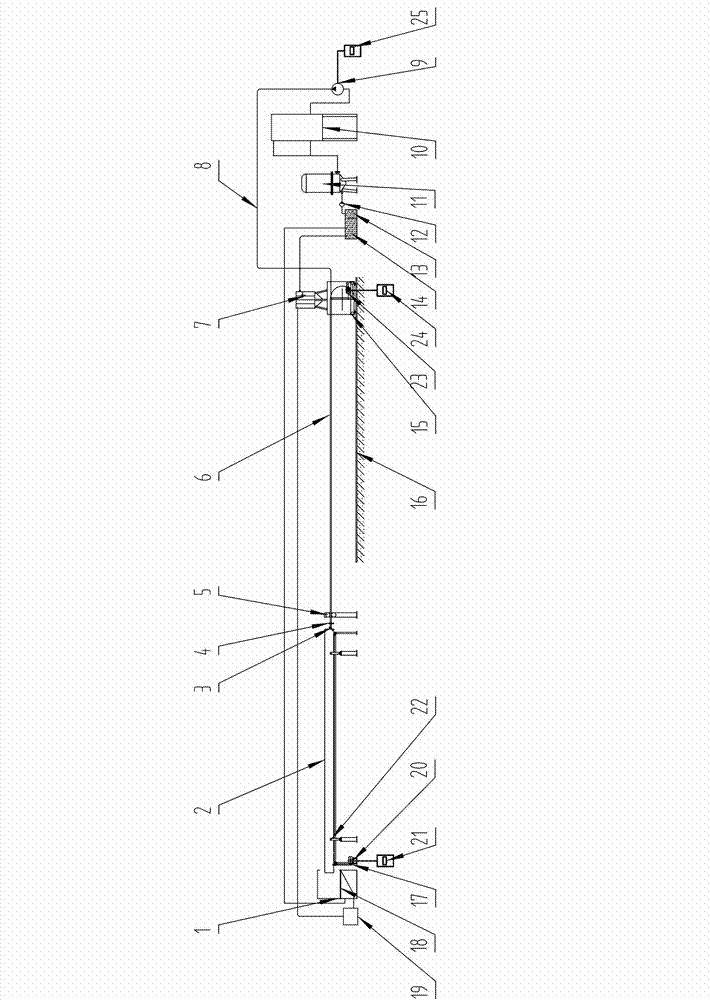

[0016] Such as figure 1 As shown, the high-pressure water jet sandblasting production line for the inner surface of pipes of the present invention includes a high-pressure water generation system, an abrasive supply system, an abrasive circulation system, a water circulation system, a pipe rotation drive mechanism 17, a nozzle 3 and a nozzle moving mechanism. The pipe fittings 2 to be processed are mounted on the pipe rotation driving mechanism 17, and driven by the pipe rotation driving mechanism 17, the pipe fittings 2 rotate. The nozzle 3 and the abrasive supply system are installed on the nozzle moving mechanism together, and the abrasive supply system moves synchronously with the nozzle 3, so that the sand delivery distance is shortened and the sand-water two-phase flow is stable and uniform, compared with the existing high-press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com