Method for automatically heating pop-top can

An automatic heating and canning technology, which is applied to food heating containers, packaged foods, containers, etc., can solve the problems of high steam pressure, long heating time, bursting cans, etc., and achieve the effect of reducing pollution and alkalinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

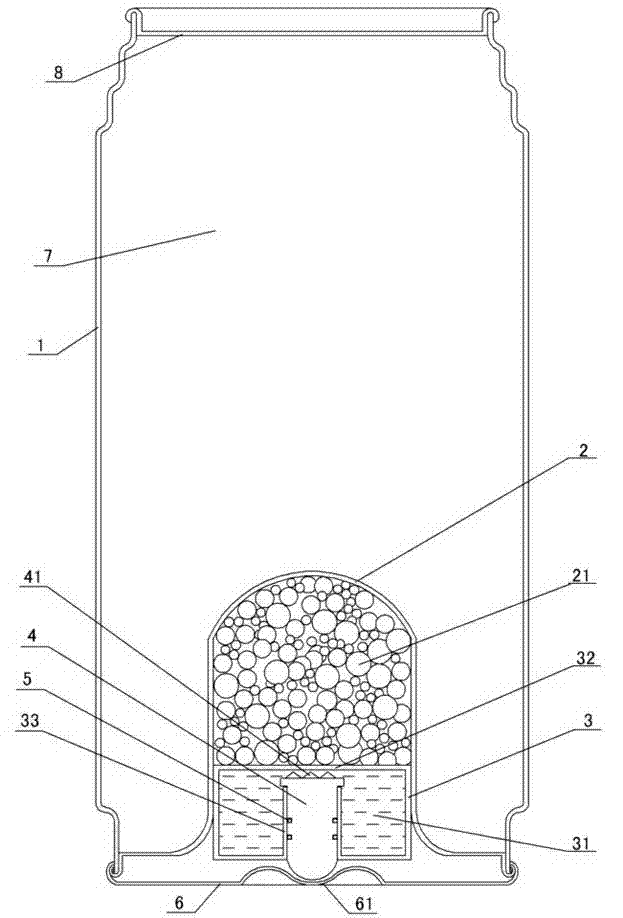

Image

Examples

Embodiment

[0026] Examples: Through the specific examples of the present invention given below, the present invention can be further clearly understood, but they are not limitations of the present invention.

[0027] 1. Pulverize and mix according to the weight ratio of 95% calcium oxide, 4.5% microcrystalline cellulose, and 0.5% magnesium stearate, and punch it into two kinds of A and B combination round granules with diameters of 2mm and 5mm;

[0028] 2. Punch the calcium chloride into a type C round granule with a diameter of 2mm;

[0029] 3. Take by weighing 8.5 g of calcium oxide round granules with a diameter of 2 mm, 33.5 g of calcium oxide round granules with a diameter of 5 mm, and 4.7 g of calcium chloride round granules with a diameter of 2 mm and mix them evenly to make three combination granules. The three-combination granules are filled on the top of the heating tank;

[0030] 4. Put two O-shaped sealing rings in the groove of the piston and install them in the piston guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com