Method for treating wastewater containing heavy metal ions of vanadium, nickel, lead, chromium and equipment thereof

A technology of heavy metal ions and metal ions, which is applied in the chemical industry, can solve problems such as large doses of chemicals, secondary pollution of the environment, and ineffective treatment effects, and achieve the effect of reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

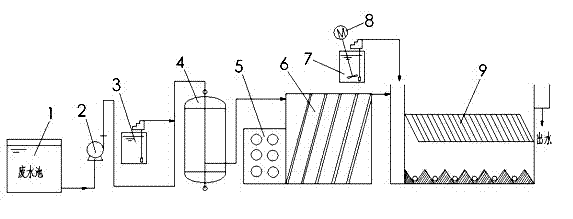

[0033] A treatment process for heavy metal ions containing vanadium, nickel, lead, chromium, etc. The waste water is pumped out from the waste water pool 1 by the waste water pump 2, and the pH value is adjusted to about 5.3-5.8 by the pH adjustment device 3 equipped with acid, and then After the pre-sand filter 4 is filtered, the multi-dimensional electrochemical composite treatment device 6 is used for secondary treatment; during the multi-dimensional electrochemical composite treatment, after the heavy metal ions pass through the electrolyzed water on the anode plate, hydrogen ions are consumed, hydroxide ions are increased, and combined with hydrogen Oxygen radicals are combined to form hydroxide; and under the combined action of polyacrylamide, the coagulant aid dosing device 7 equipped with polyacrylamide, the sediment is efficiently precipitated in the inclined plate sedimentation tank 9, and the supernatant Medium heavy metal content is removed.

[0034] The principle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com