Washing-resistant antistatic coating and preparation method thereof

An anti-static coating and washing-resistant technology, which is applied in the direction of conductive coatings, polyester coatings, polyurea/polyurethane coatings, etc., can solve the problems of poor operability, poor adhesion and oil resistance, and difficult processing of conductive materials. The effect of convenient processing, strong adhesion, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

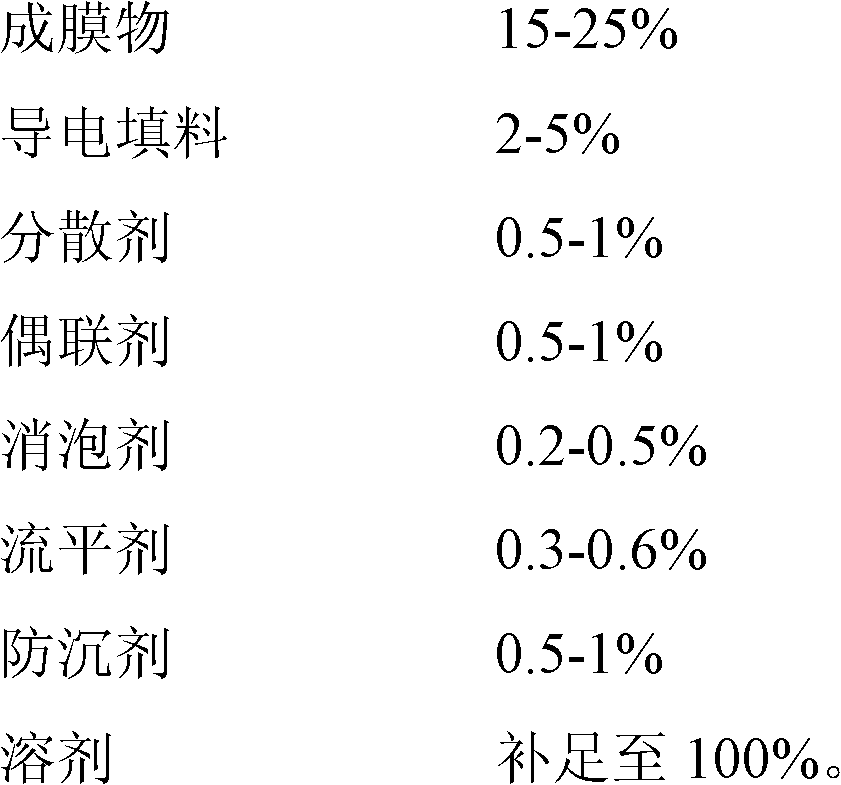

Method used

Image

Examples

Embodiment 1

[0033] 15% by mass percent of saturated polyester resin L411 (100% saturation) was dissolved in 17.7% by mass of butyl acetate and 5% of cyclohexanone, and mixed uniformly to obtain a saturated polyester resin solution; In this solution, add conductive carbon black, dispersant (DA-168) and coupling agent (TG-27) with a mass percentage of 4%, 0.8% and 0.5%, and disperse uniformly at a high speed of 2000r / h for 2h to obtain A uniformly dispersed mixture; add 0.4%, 0.5% and 0.5% of the mass percent of the defoamer (0.2% of TEGO ADDID900 and 0.2% of TEGO Airex900), leveling agent (LA-3088) to the above-mentioned uniformly dispersed mixture ) and anti-sedimentation agent (0.2% of D200X and 0.3% of R972), and supplemented with 9% and 46.6% of N-methylpyrrolidone and ethyl acetate by mass percentage, and dispersed at a high speed of 1800r / h for 0.5h. Wash-resistant anti-static coatings are required.

Embodiment 2

[0035] The mass percentage is 23% saturated polyester resin L952 (saturation is 100%) dissolved in mass percentage is 21% ethyl acetate and 3% N-methylpyrrolidone, after mixing uniformly, saturated polyester resin is obtained solution; in this solution, adding mass percent respectively is 3%, 2%, 1% and 1% conductive carbon black, conductive graphite, dispersant (0.5% Deqian 201, 0.2% lecithin and 0.3% LBD -1) and coupling agent (0.5% of Z-6040 and 0.5% of YB-403), uniformly dispersed at 1800r / h for 1 hour at a high speed to obtain a uniformly dispersed mixture; add mass percentages to the above-mentioned uniformly dispersed mixture in sequence 0.5%, 0.5% and 1% of defoamer (EFKA2720), leveling agent (0.4% of SG-306 and 0.1% of BYK-333) and anti-settling agent (0.5% of MT6900-20X and 0.5% of BYK-410), and supplementing mass percent is 4% and 40% N-methylpyrrolidone and butyl acetate, after 1900r / h high-speed dispersion uniformly 1h, required washing-resistant antistatic coatin...

Embodiment 3

[0037] Dissolve the hydroxyacrylic resin SIADD-525 of 22% by mass in 18% ethyl acetate and 9% cyclohexanone, and mix well to obtain a hydroxyacrylic resin solution; add mass The percentages are 4%, 1% and 1% of conductive carbon black, dispersant (0.5% of TRM2400 and 0.5% of Deqian 201) and coupling agent (0.3% of Z-6040 and 0.7% of TG-27), Disperse at a high speed of 1900r / h for 3 hours to obtain a uniformly dispersed mixture; in the above-mentioned uniformly dispersed mixture, add successively mass percentages of 0.4%, 0.6% and 0.5% defoamers (0.2% TEGO Airex901W, 0.1% TEGO ADDID900 and 0.1% TEGO Airex900), leveling agent (0.3% Sakura SKR-333 and 0.3% LA-3088) and anti-settling agent (0.3% R972 and 0.2% BYK-410), and supplement the mass percentage 29% and 14.5% of cyclohexanone and butyl acetate, 2000r / h high-speed dispersion evenly for 0.7h to prepare the required wash-resistant antistatic coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com