A Novel Magnesium Deep Eutectic Solvent

A deep eutectic solvent, a new technology, applied in the field of new magnesium deep eutectic solvent, to achieve the effect of simple production method, stable electrochemical properties, and stable chemical properties at room temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

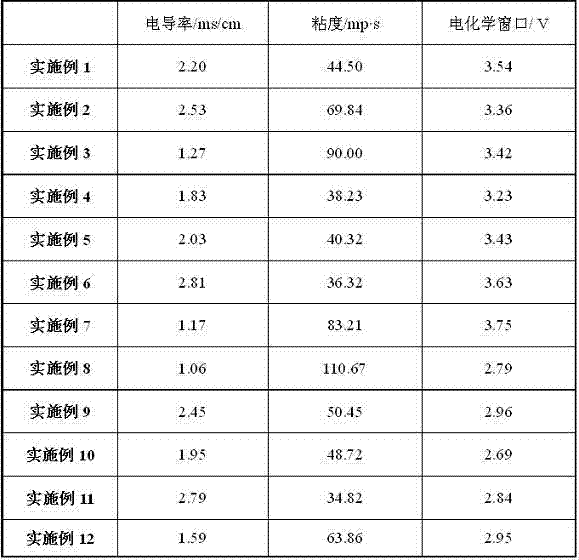

[0015] Example 1 A new type of magnesium deep eutectic solvent, the deep eutectic solvent refers to adding 4.786g choline chloride (ChCl) to 47.855g N,N-dimethylformamide (DMF) solution at 20°C, continuously Stir until the mixed solution is obtained after all dissolve; then 10.528g magnesium chloride hydrate (MgCl 2 ·nH 2 O) Add it to 52.641g of the mixed solution at 20°C, and keep stirring until it is completely dissolved; the amount of choline chloride (ChCl) added is 10% of the mass of N,N-dimethylformamide (DMF) solution %; Magnesium chloride hydrate (MgCl 2 ·6H 2 O) The amount added is 20% of the mass of the mixed solution.

[0016] The deep eutectic solvent is a homogeneous, stable, colorless and transparent liquid at room temperature. The viscosity at room temperature is 44.50mp·s, and the conductivity is 2.20ms / cm. The electrochemical test shows that the system has good electrochemical stability, and the electrochemical stability window is 3.54V. The solvent...

Embodiment 2

[0017] Example 2 A new type of magnesium deep eutectic solvent, the deep eutectic solvent refers to adding 38.113g of choline chloride (ChCl) to 47.641g of N,N-dimethylformamide (DMF) solution at 70°C, continuously Stir until the mixed solution is obtained after all dissolve; then 15.201g of magnesium chloride hydrate (MgCl 2 ·6H 2 O) and 10.000g of other metal chlorides were added to 85.754g of the mixed solution at 70°C and stirred continuously until all of them were dissolved; the amount of choline chloride (ChCl) added was N,N-dimethylformamide (DMF) 80% of the mass of the solution; hydrated magnesium chloride (MgCl 2 2H 2 O) The amount added is 18% of the mass of the mixed solution; the amount of other metal chlorides added is 12% of the mass of the mixed solution.

[0018] Wherein: other metal chlorides are zinc chloride.

[0019] The deep eutectic solvent is a homogeneous, stable, colorless and transparent liquid at room temperature. The viscosity at room tem...

Embodiment 3

[0020] Example 3 A new type of magnesium deep eutectic solvent, the deep eutectic solvent refers to adding 31.761g of choline chloride (ChCl) to 47.641g of N,N-dimethylformamide (DMF) solution at 50°C, continuously Stir until all dissolved to obtain a mixed solution; then 15.000g of magnesium chloride hydrate (MgCl 2 ·nH 2 O) and other metal chlorides are added to the mixed solution at 50°C and stirred continuously until they are completely dissolved; the amount of choline chloride (ChCl) added is N,N-dimethylformamide (DMF) solution 67% of mass; magnesium chloride hydrate (MgCl 2 4H 2 O) The amount added is 19% of the mass of the mixed solution; the amount of other metal chlorides added is 31% of the mass of the mixed solution.

[0021] Wherein: other metal chlorides are mixed with 10.000g of zinc chloride and 15.000g of copper chloride.

[0022] The deep eutectic solvent is a homogeneous, stable liquid at room temperature. The viscosity at room temperature is 90.0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com