Method for preparing magnesium metal through electrolysis by using novel magnesium deep eutectic solvent

A technology of deep eutectic solvent and metal magnesium, which is applied in the improvement of process efficiency, photography process, instruments, etc., to achieve the effect of strong resistance to water influence, good deposition effect and simple system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

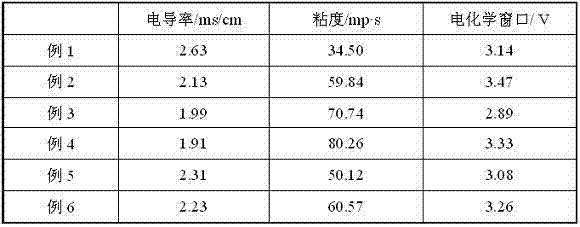

Embodiment 1

[0018] Example 1 A method for preparing metallic magnesium by electrolysis of a novel magnesium eutectic solvent. The temperature of the eutectic solvent is raised to 20°C. At this temperature, 0.3% of the mass of the solvent is added with additives, and a uniform and stable solution is obtained by stirring; the solution Deposit for 0.5 h under the condition that the working electrode is a copper sheet electrode and the constant potential is -2.4V, and then metal magnesium or magnesium alloy is obtained.

[0019] Among them: the deep eutectic solvent refers to adding choline chloride to N,N-dimethylformamide solution at 20°C and stirring continuously until it is completely dissolved to obtain a mixed solution; then magnesium chloride hexahydrate and other metals Chloride is added to the mixed solution at 20°C and stirred continuously until it is completely dissolved; the addition of choline chloride is 10% of the mass of N,N-dimethylformamide solution; the addition of magn...

Embodiment 2

[0021] Example 2 A method for preparing metal magnesium by electrolysis of a novel magnesium eutectic solvent, heating the eutectic solvent to 70°C, adding additives at 1.5% of the mass of the solvent at this temperature, and stirring to obtain a uniform and stable solution; the solution Deposit for 3.5 h under the condition that the working electrode is an aluminum sheet electrode and the constant potential is -2.9V, and then metal magnesium or magnesium alloy is obtained.

[0022] Among them: the deep eutectic solvent refers to adding choline chloride to the N, N-dimethylformamide solution at 70 °C, stirring continuously until all of it is dissolved to obtain a mixed solution; then adding magnesium chloride hexahydrate and other metals Chloride is added to the mixed solution at 70°C, and it is stirred continuously until it is completely dissolved; the addition amount of choline chloride is 80% of the quality of N, N-dimethylformamide solution; the addition amount of mag...

Embodiment 3

[0024] Example 3 A method for preparing metallic magnesium by electrolysis of a novel magnesium eutectic solvent. The eutectic solvent is heated to 50° C., and at this temperature, additives are added according to 0.8% of the mass of the solvent, and a uniform and stable solution is obtained by stirring; the solution Deposit for 2.5 h under the condition that the working electrode is a silver plate electrode and the constant potential is -2.5V, and then metal magnesium or magnesium alloy is obtained.

[0025] Among them: the deep eutectic solvent refers to adding choline chloride to N,N-dimethylformamide solution at 50°C and stirring continuously until it is completely dissolved to obtain a mixed solution; then magnesium chloride hexahydrate and other metals Chloride is added to the mixed solution at 50°C and stirred continuously until it is completely dissolved; the addition of choline chloride is 20% of the quality of the N,N-dimethylformamide solution; the addition of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com