Weaving method of three-dimensional T-shaped tubular woven fabrics formed integrally

A technology of integral molding and woven fabrics, applied in fabrics, textiles, papermaking, textiles, etc., can solve problems such as wrinkling at joints, expensive processing and manufacturing costs, and limited uses, so as to facilitate weaving, reduce design time, and reduce costs. The effect of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] A kind of weaving method of the T-shaped tubular woven fabric of three-dimensional integral formation, its steps are as follows:

[0035] (1) Design the overall pattern, which consists of three parts: the tube area, the outline area and the joint area outside the tube;

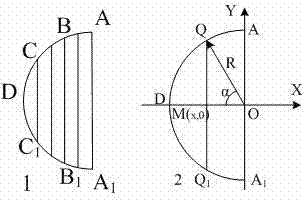

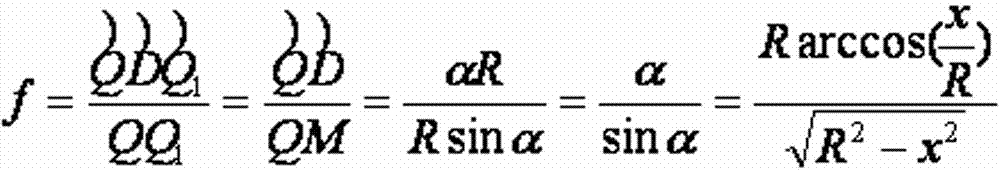

[0036] (2) Design the fabric structure of the tube area. The tube area part is a two-layer fabric separated from the upper and lower parts. Each layer can be composed of at least one layer of warp and weft yarns interwoven with a 2 / 2 twill weft weaving layer with a core thread. , each layer adopts 2 / 2 twill weave, and the ratio of the number of core threads to weft yarns is 1:2;

[0037] (3) Design the weave structure of the outline area, the weave of the outline area adopts the weave structure that makes the core line float on the front and back of the fabric;

[0038] (4) Design the tissue structure of the junction area outside the pipe. The outer part of the pipe adopts a four-layer junction organiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com