An intelligent control system and control method for an emulsion pumping station

An intelligent control system, emulsion pump station technology, applied in pump control, liquid variable volume machinery, machine/engine, etc. Small volume, burnout of switches and motors, etc., to reduce ineffective operation, prevent burnout of equipment, and save electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described below in the form of specific examples, but the present invention is by no means limited to the following examples.

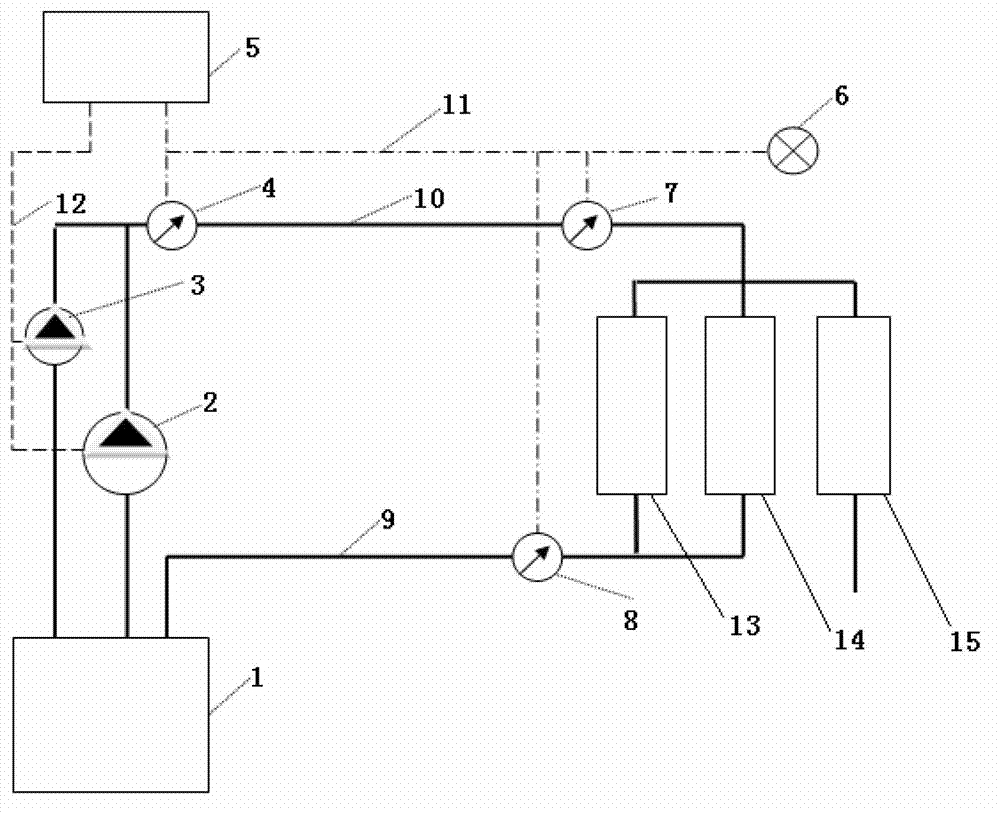

[0015] An intelligent control system for an emulsion pumping station, such as figure 1 As shown, the intelligent control system of the emulsion pump station includes an emulsion tank 1, a first emulsion pump 2, a second emulsion pump 3, an emulsion pump station liquid supply sensor 4, a controller 5, a coal mining Machine start-stop sensor 6, working surface liquid inlet sensor 7, working surface liquid return sensor 8, working surface liquid return pipeline 9, working surface liquid inlet pipeline 10, sensor signal line 11, emulsion pump control signal line 12 , move the support equipment 13, transfer the carrier equipment 14 and the advanced processing equipment 15, move the support equipment 13, transfer the carrier equipment 14 and the advanced processing equipment 15 in parallel, the first emulsion pump 2 and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com