An all-round electrophoretic coating device for the production of automobile shells

A technology of electrophoretic coating and automobile shell, applied in the direction of electrolytic coating, electrophoretic plating, coating, etc., can solve the problem that the quality of electrophoretic coating on the surface of automobile shell cannot be guaranteed, the cost of automobile shell coating increases, and the electrophoretic coating is uneven and other problems, to achieve the effect of clamping and fixing and position transfer, improving utilization rate and saving pure water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

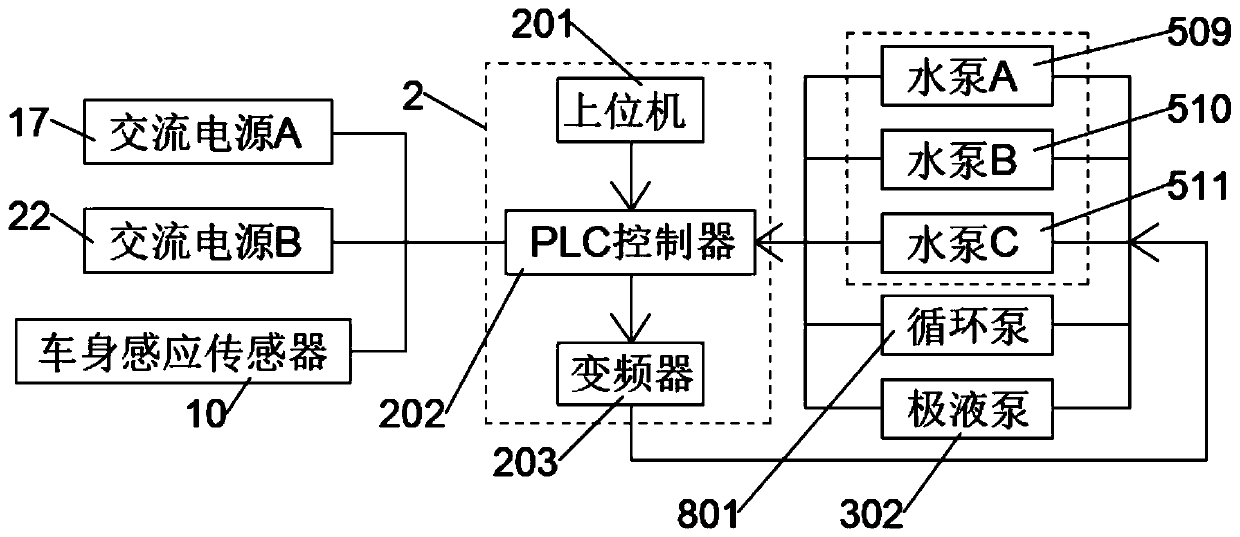

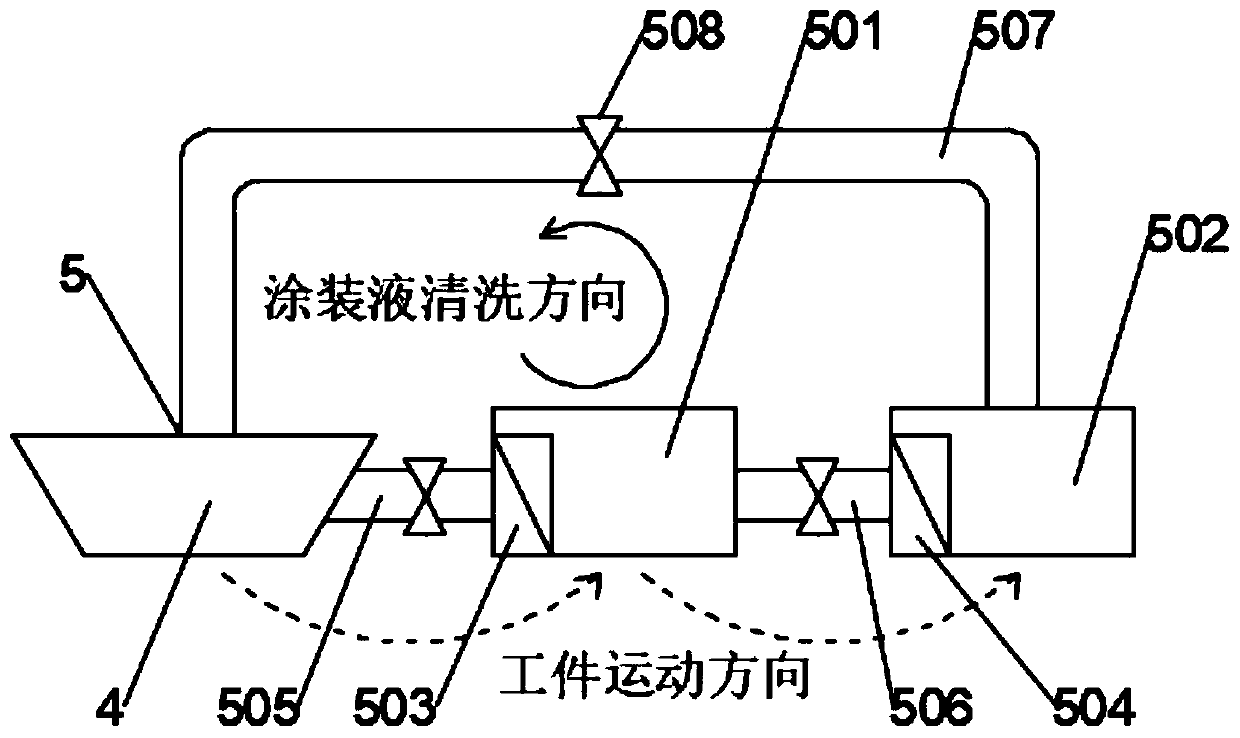

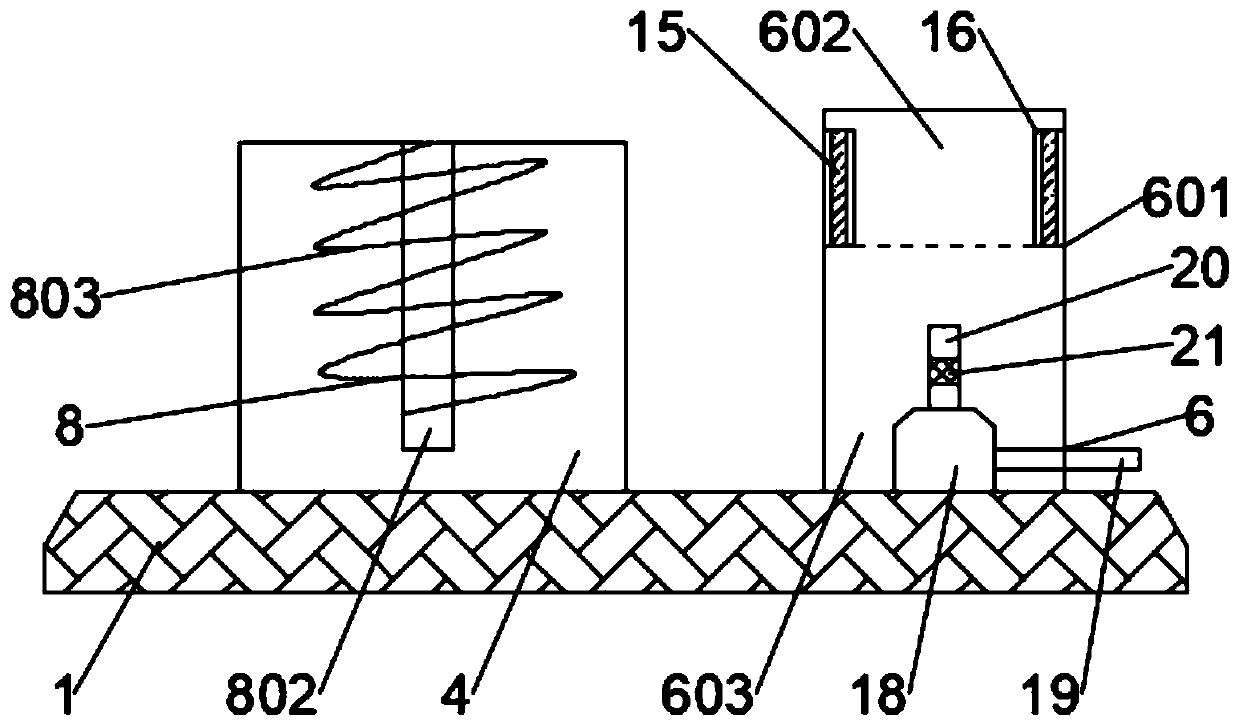

[0044] Such as Figure 1 to Figure 6 As shown, the present invention provides an all-round electrophoretic coating device for the production of automobile shells, including a coating workbench 1, and a frequency conversion adjustment device 2 and an anode liquid supply device 3 are arranged above the painting workbench 1 , a coating tank 4 filled with paint, a closed-loop cleaning device 5 for cleaning the surface of the workpiece after painting, a combined dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com