Method for evaluating hydrochloric acid and corrosion inhibitor used for cleaning, and working liquid thereof

A technology of hydrochloric acid corrosion inhibitor and evaluation method, which is applied in material analysis by observing the effect on chemical indicators, weighing by removing certain components, and analyzing by chemical reaction of materials, etc. On-site test, complicated operation, and many related test equipments, etc., achieve the effect of simple and easy test process, ensure operation safety, and short test time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] The infrastructure boiler of a power plant in Hebei Southern Power Grid was chemically cleaned by hydrochloric acid cleaning process.

[0078] In the first step, take industrial hydrochloric acid for on-site cleaning before cleaning and measure its acid concentration to be 30.8%.

[0079] In the second step, a saturated solution of barium chloride was added to the hydrochloric acid taken on site, and a large amount of white precipitate was formed, indicating that the hydrochloric acid contained a large amount of sulfate radicals, which was not suitable for chemical cleaning.

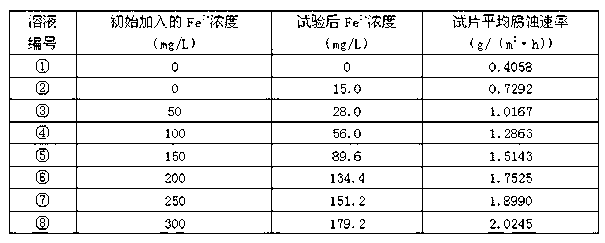

[0080] In the third step, in order to analyze and evaluate the performance of the corrosion inhibitor, take analytical pure hydrochloric acid and on-site industrial hydrochloric acid to make 5% hydrochloric acid solution, add 0.3% corrosion inhibitor to it; put the beakers containing the two solutions into the water bath respectively In the pot, cover the lid, and connect the condensing reflux tub...

Embodiment 2

[0083] The infrastructure boiler of a power plant in Hebei Southern Power Grid is chemically cleaned, and the cleaning process uses hydrochloric acid cleaning process.

[0084] In the first step, take the hydrochloric acid in the on-site acid car before cleaning and measure the acid concentration to be 30.6%.

[0085] In the second step, a saturated solution of barium chloride was added to the hydrochloric acid taken on site, and no white precipitate occurred, indicating that there was no large amount of sulfate radicals in the hydrochloric acid.

[0086] In the third step, in order to analyze and evaluate the quality of hydrochloric acid and corrosion inhibitor for on-site cleaning, prepare the following solution:

[0087] ① Analytical pure hydrochloric acid is made into 5% hydrochloric acid solution, and 0.3% corrosion inhibitor is added;

[0088] ② On-site industrial hydrochloric acid is made into 5% hydrochloric acid solution, and 0.3% corrosion inhibitor is added;

...

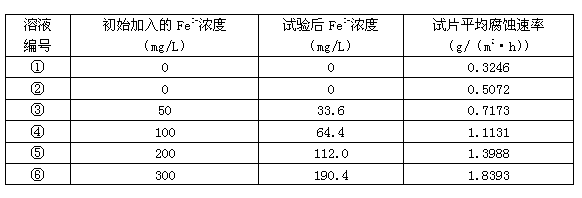

Embodiment 3

[0100] A power plant in Hebei Southern Power Grid operates boilers for chemical cleaning, and the cleaning process uses hydrochloric acid cleaning process.

[0101] In the first step, take the hydrochloric acid in the on-site acid car before cleaning and measure the acid concentration to be 30.9%.

[0102] In the second step, a saturated solution of barium chloride was added to the hydrochloric acid taken on site, and no white precipitate occurred, indicating that there was no large amount of sulfate radicals in the hydrochloric acid.

[0103] In the third step, in order to analyze and evaluate the performance of hydrochloric acid and corrosion inhibitor on site, prepare the following solution:

[0104] ① Analytical pure hydrochloric acid is made into 5% hydrochloric acid solution, and 0.3% corrosion inhibitor is added;

[0105] ② On-site industrial hydrochloric acid is made into 5% hydrochloric acid solution, and 0.3% corrosion inhibitor is added;

[0106] ③ On-site industr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com