A green gan-based LED epitaxial structure

An epitaxial structure, green light technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of performance degradation, lattice difference, radiation recombination efficiency decline, etc., and achieve the effect of improving high brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

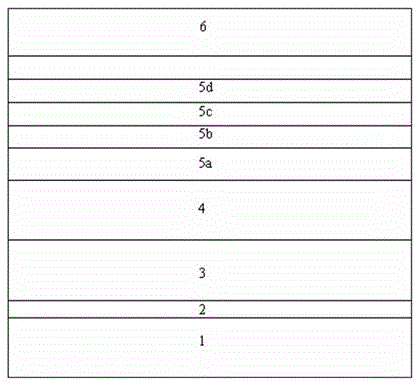

[0011] Such as figure 1 As shown, 1 is a sapphire substrate, 2 is a GaN nucleation layer, 3 is an undoped GaN layer, 4 is an n-type GaN layer, 5a is a GaN barrier layer, 5b is a buffer layer 1Gradedwell, 5c is an InGaN quantum well layer, 5d is the buffer layer 2shallowwell, 5e is the temperature-varying GaN transition layer, and 6 is the p-type GaN layer.

[0012] It can be seen from the figure that a GaN nucleation layer 2, an undoped GaN layer 3, an n-type GaN layer 4, a GaN barrier layer 5a, a first graded well of In composition, a buffer layer 5b, InGaN quantum well layer 5c, second shallowwell buffer layer 5d with graded In composition, temperature-varying GaN transition layer 5e and p-type GaN layer 6.

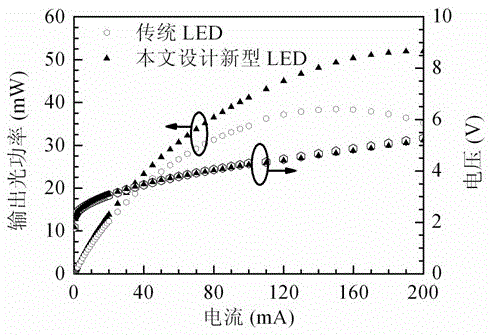

[0013] figure 2 It is a comparison chart of luminance and voltage after 10mil*12mil packaging with buffer layer Gradedwell and without buffer layer Gradedwell.

[0014] Depend on figure 2 It can be seen that the brightness of the LED with the Gradewell buffer laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com