A kind of electroluminescent material and its preparation method and light-emitting device made of the material

An electroluminescent material and solution technology, applied in luminescent materials, electro-solid devices, electrical components, etc., can solve the problems of unsatisfactory luminous brightness decay life, high production cost, harsh synthesis conditions, etc., and is conducive to industrialization promotion. , the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

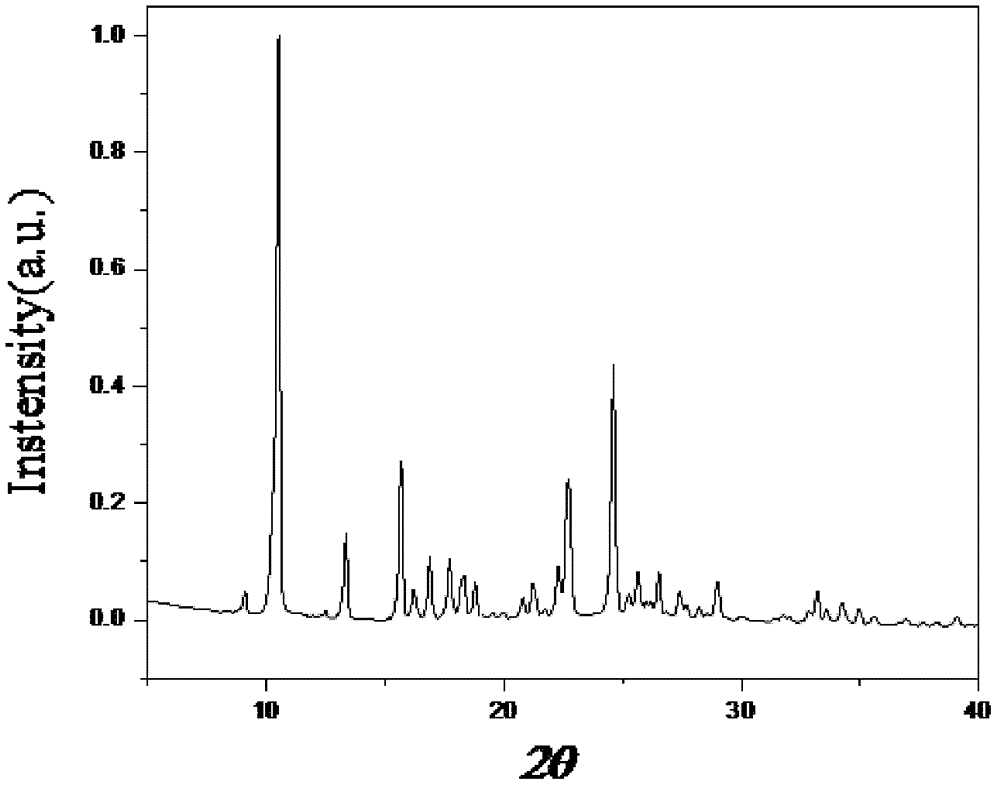

[0034] Dissolve 10g of aluminum trichloride in 60ml of deionized water to obtain an aluminum trichloride solution, dissolve 40g of 8-hydroxyquinoline in 100ml of ethanol to obtain an ethanolic solution of 8-hydroxyquinoline, mix these two solutions, It was concentrated to about 50 ml at 70°C, and then the temperature was maintained at 70°C, and a saturated solution of sodium chloride was slowly added dropwise with stirring. The yellow-green 8-hydroxyquinoline aluminum was gradually precipitated, and when the reaction was completed, the precipitate was filtered. The crude product was washed three times with deionized water and five times with methanol, and then vacuum-dried at 70° C. to obtain the final product. The XRD pattern of the product is as follows figure 1 shown.

Embodiment 2

[0036]Dissolve 20g of aluminum isopropoxide in 100ml of ethanol to obtain an aluminum isopropoxide solution, and dissolve 52g of 8-hydroxyquinoline in 100ml of acetone to obtain an acetone solution of 8-hydroxyquinoline. °C was concentrated to about 50 ml, then the temperature was maintained at 70 °C, and a saturated sodium sulfate solution was slowly added dropwise with stirring. The yellow-green 8-hydroxyquinoline aluminum was gradually precipitated, and when the reaction was completed, the precipitate was filtered. The crude product was washed 5 times with deionized water and 7 times with tetrahydrofuran, and then vacuum-dried at 70° C. to obtain the final product.

Embodiment 3

[0038] Dissolve 30g of aluminum sulfate octadecahydrate in 60ml of deionized water to obtain a solution of aluminum sulfate octadecahydrate, and dissolve 49g of 8-hydroxyquinoline in 100ml of methanol to obtain a methanol solution of 8-hydroxyquinoline. After mixing these two solutions, It was concentrated to about 50 ml at 60°C, and then the temperature was maintained at 60°C, and a saturated sodium sulfate solution was slowly added dropwise with stirring. The yellow-green 8-hydroxyquinoline aluminum was gradually precipitated, and when the reaction was completed, the precipitate was filtered. The crude product was washed 7 times with deionized water and 3 times with tetrahydrofuran, and then vacuum-dried at 70° C. to obtain the final product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com