Preparation method and application of water-based general automobile coating resin

A general-purpose resin, water-based resin technology, used in polyurea/polyurethane coatings, coatings, pigment pastes, etc., can solve the problems of poor storage stability, floating color, general tinting strength and color development performance, etc. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

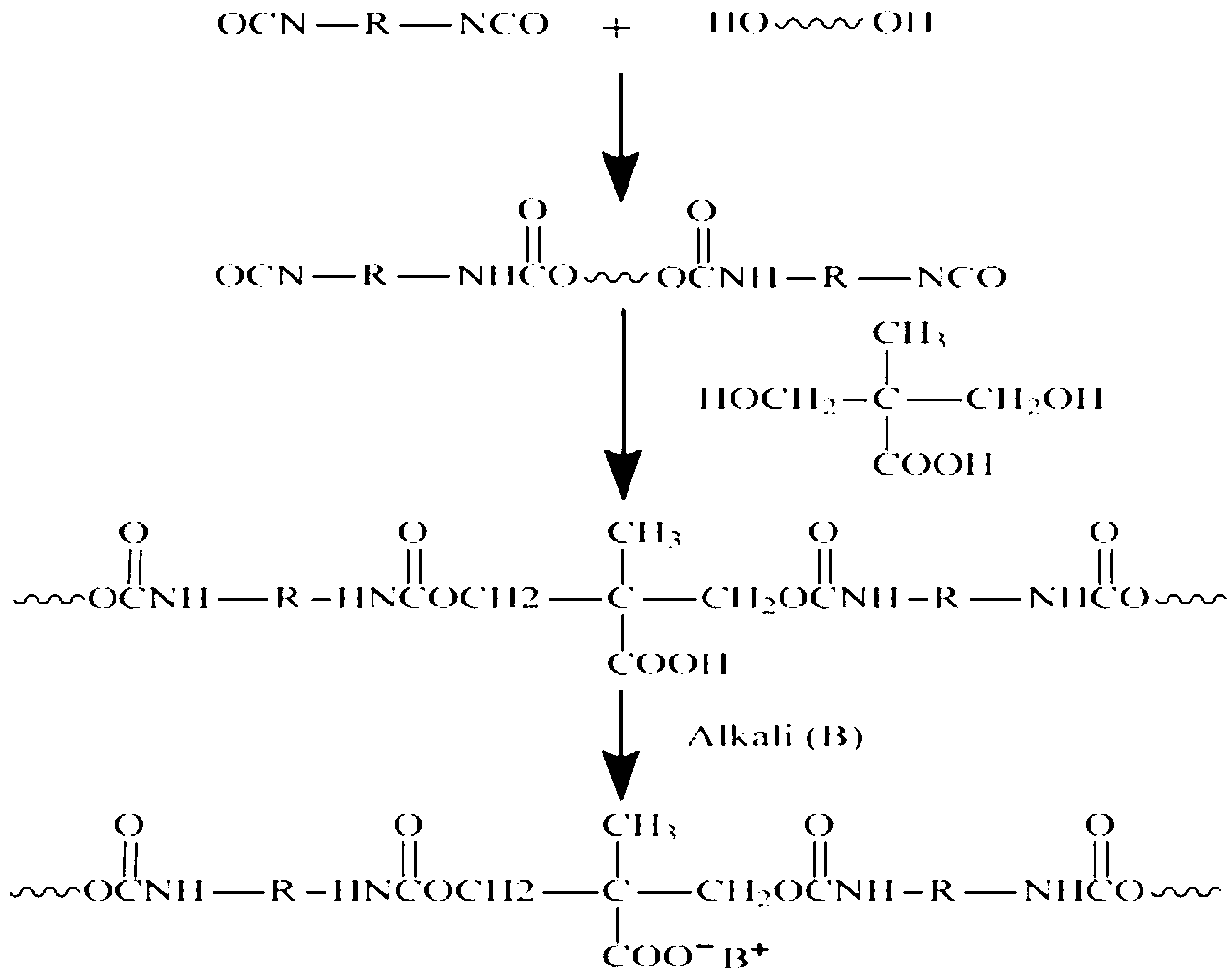

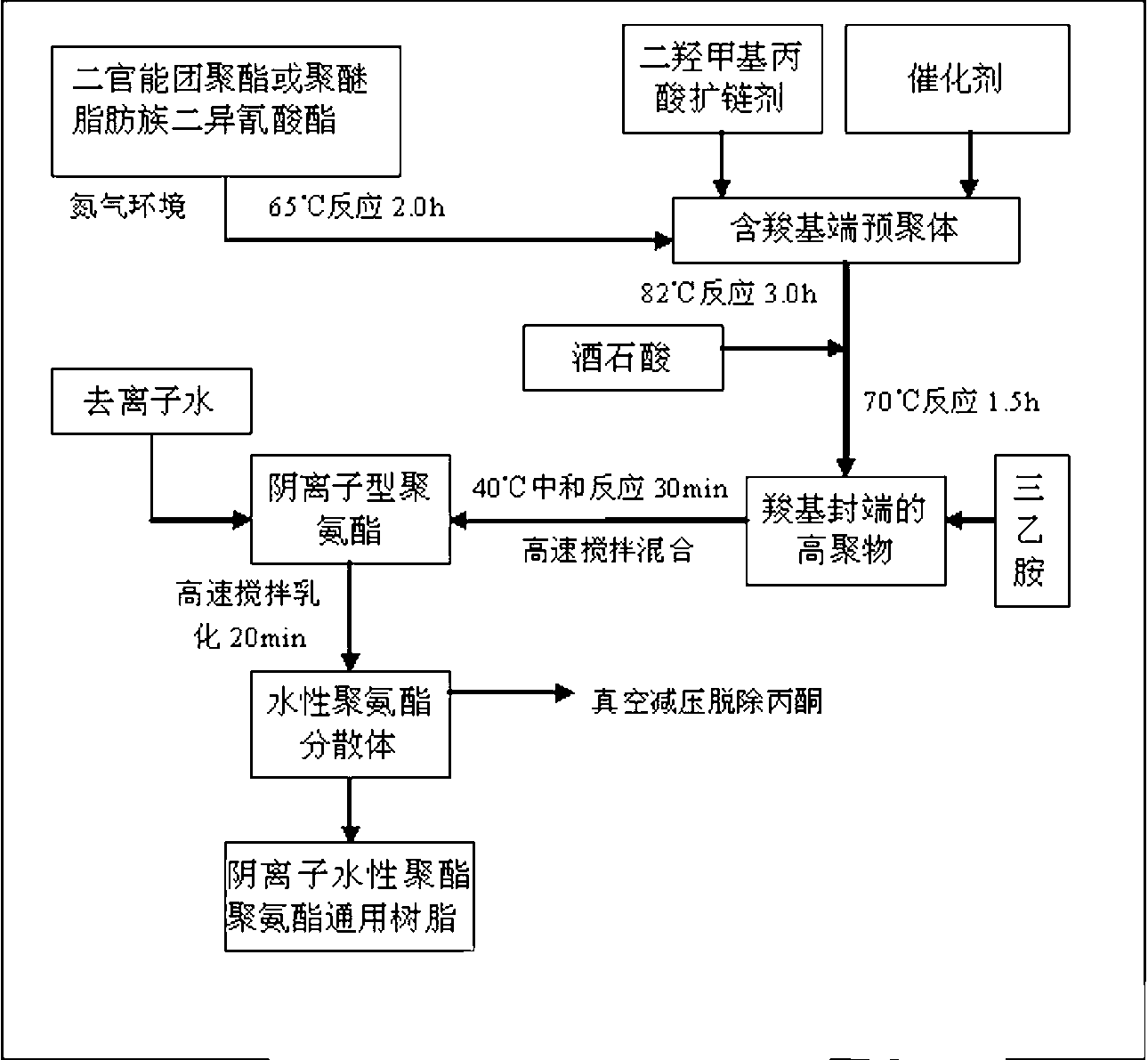

[0051] according to figure 1 , figure 2 Shown, the present invention has included the following steps:

[0052] 1. Preparation of prepolymers containing carboxyl groups: Mix 50~70kg of difunctional polyester or polyether dehydrated at 100~140℃ and 30~50kg of aliphatic diisocyanate into the reaction kettle, and gradually raise the temperature under nitrogen protection To 60~70°C, keep the reaction at 60~70°C for 1.0~3.0h, make the NCO content in the system reach the theoretical value, and obtain the carboxyl-terminal prepolymer;

[0053] 2. Chain extension of prepolymer: Weigh 4~6kg of dimethylolpropionic acid, fully dissolve it in N-methylpyrrolidone and add it, add 0.1~1.3kg of catalyst, heat up to 78~86℃ for reaction 2~4h, continue to add 4~6kg of tartaric acid, carry out the chain extension reaction at 60~80°C for 1~2h, add acetone and other polar solvents to reduce the viscosity, and obtain a carboxyl-terminated polymer solution;

[0054] 3. Neutralization and emulsifi...

Embodiment 2

[0057] according to figure 1 , figure 2 Preparation of the carboxy-terminal-containing prepolymer shown: Mix 60kg of difunctional polyester or polyether dehydrated at 120°C and 40kg of aliphatic diisocyanate into the reactor, gradually raise the temperature to 65°C under nitrogen protection, and keep at React at 65°C for 2.0 hours to make the NCO content in the system reach the theoretical value.

[0058] Chain extension of the prepolymer: Weigh 5kg of dimethylolpropionic acid, fully dissolve it in N-methylpyrrolidone, add 0.2kg of catalyst, raise the temperature to about 82°C for 3 hours, and continue to add 5kg of tartaric acid, Carry out chain extension reaction at 70° C. for 1.5 h, add acetone and other polar solvents to reduce viscosity, and obtain carboxyl-terminated polymer solution.

[0059] Neutralization and emulsification of high polymer: cool down the high polymer, when the temperature reaches about 40°C, add 5kg of triethylamine neutralizing agent, stir and mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com