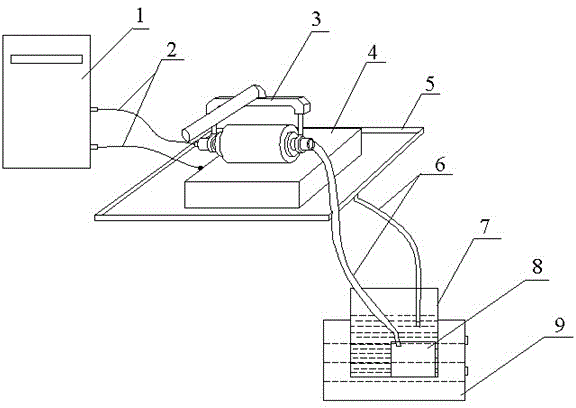

Rolling brush type micro-arc oxidation processing method and device

A technology of micro-arc oxidation and treatment method, applied in anodizing and other directions, can solve the problems of low production efficiency, fixed-point micro-arc oxidation method cannot achieve continuous treatment, etc., and achieves the effects of convenient operation, reduced cost, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

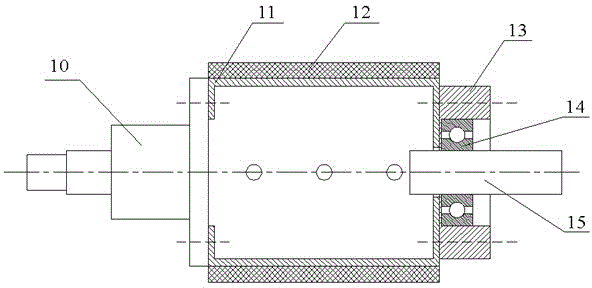

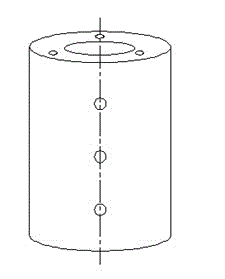

Embodiment 1

[0033] Use this device to carry out micro-arc oxidation treatment on the surface of a magnesium alloy plate with an area of 50cm×50cm, using a power frequency AC power supply, the workpiece is connected to one of the output terminals of the AC power supply through a wire, and the roller brush cathode is connected to the The other output end of the power supply; start the submersible pump, the electrolyte is transferred through the electrolyte pipe, and enters the roller brush cathode stainless steel cylinder through the catheter tube, and the electrolyte is absorbed by the PVA collodion sleeve through the through hole of the stainless steel cylinder, and the PVA collodion The water absorption rate can reach more than 10 times its own weight, and the water retention is very good when it is not subjected to external force, and the water is quickly discharged when it is pressed. Moreover, in sports use, due to the strong adsorption force of water, it can form a certain resistanc...

Embodiment 2

[0036] Wrap the stainless steel cylinder with a 1.5cm thick PVA collodion cover, the thickness of the collodion at both ends of the collodion cover is 0.2cm, and the others are the same as in Example 1. Effect is the same as embodiment 1.

[0037]

Embodiment 3

[0039] Wrap the stainless steel cylinder with a 3.5cm thick PVA collodion sleeve, the thickness of the collodion on both ends of the collodion sleeve is 0.2cm, and the roller brush cathode rolls back and forth on the surface of the workpiece at a speed of 40r / min. Others are the same as in Example 1. As a result, a uniform smooth film layer can be seen on the surface of the workpiece.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com