Sealing assembly for battery, manufacturing method of sealing assembly for battery and lithium ion battery

A technology for sealing components and manufacturing methods, which is applied to battery pack parts, sealing materials, electrical components, etc., can solve the problems that the solder cannot completely flow and fill the welding seam, and the air tightness of the sealing components is poor, so as to achieve air tightness and Good peel strength, stable structure, and the effect of increasing the brazing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

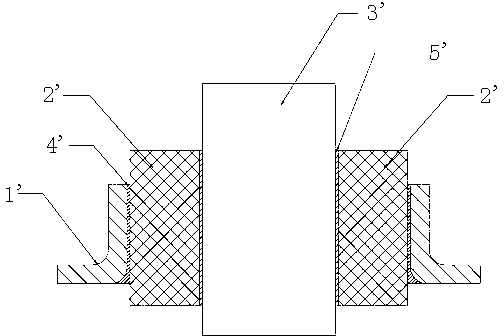

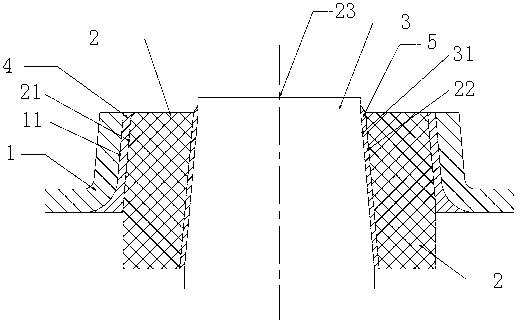

[0046] This embodiment 1 is used to illustrate the sealing assembly of the positive electrode of the battery disclosed in the present invention and its preparation method;

[0047] Step 1. Provide an alumina ceramic ring, an aluminum-magnesium alloy ring, and a titanium metal core column. The middle part of the aluminum-magnesium alloy ring is formed with a mounting hole, and the middle part of the alumina ceramic ring is formed with a connecting hole. The joint surface of the alloy ring and the alumina ceramic ring, and the connection surface of the alumina ceramic ring and the titanium metal core post are made into a torus with an inclination angle of 5 degrees with the centerline 23 of the ceramic ring; The first joint surface formed by the outer surface of the alumina ceramic ring, the second joint surface matched with the installation hole wall of the aluminum-magnesium alloy ring is made to be 5 degrees from the center line 23 of the ceramic ring, and the titanium metal c...

Embodiment 2

[0050] This embodiment 2 is used to illustrate the sealing assembly of the positive electrode of the battery disclosed in the present invention and its preparation method;

[0051] Step 1. Provide a ceramic ring, a metal ring, and a stem, wherein a mounting hole is formed in the middle of the metal ring, a connection hole is formed in the middle of the ceramic ring, the stem is an aluminum metal stem, and the ceramic ring is Zirconia ceramic ring, the metal ring is an aluminum-magnesium alloy ring, the joint surface of the metal ring and the ceramic ring is made into a torus with an inclination angle of 15 degrees from the center line of the ceramic ring, and the ceramic ring and the The connection surface of the stem column is made into a circular surface with an inclination angle of 20 degrees with the center line of the ceramic ring; that is to say, the outer surface of the ceramic ring forms the first joint surface, and the installation hole wall of the metal ring cooperate...

Embodiment 3

[0054] This embodiment 3 is used to illustrate the sealing assembly of the negative electrode of the battery disclosed in the present invention and its preparation method;

[0055] Step 1. Provide a ceramic ring, a metal ring, and a stem, wherein a mounting hole is formed in the middle of the metal ring, a connection hole is formed in the middle of the ceramic ring, the stem is a titanium metal stem, and the ceramic ring is Zirconia ceramic ring, the metal ring is an aluminum-manganese alloy ring, the joint surface of the metal ring and the ceramic ring is made into a torus with an inclination angle of 10 degrees from the center line of the ceramic ring, and the ceramic ring and the The connecting surface of the stem is made into a circular surface with an inclination angle of 10 degrees to the center line of the ceramic ring; that is to say, the outer surface of the ceramic ring forms the first joint surface, and the installation hole wall of the metal ring is matched with it....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com