A brushless DC motor controller with automatic adjustment of phase advance angle

A brushless DC motor, brushless motor technology, applied in the direction of single motor speed/torque control, electronic commutator, sustainable manufacturing/processing, etc. The control chip IC can not be like the software solution, etc., to achieve the effect of improving efficiency, high magnification, and satisfying multi-speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings.

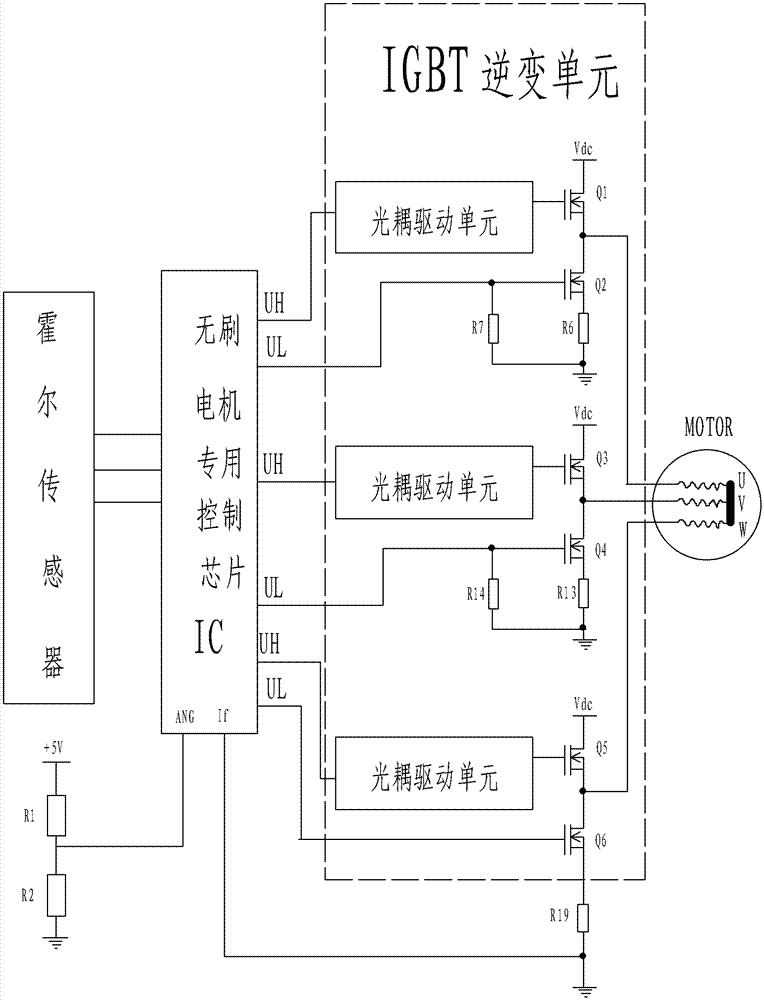

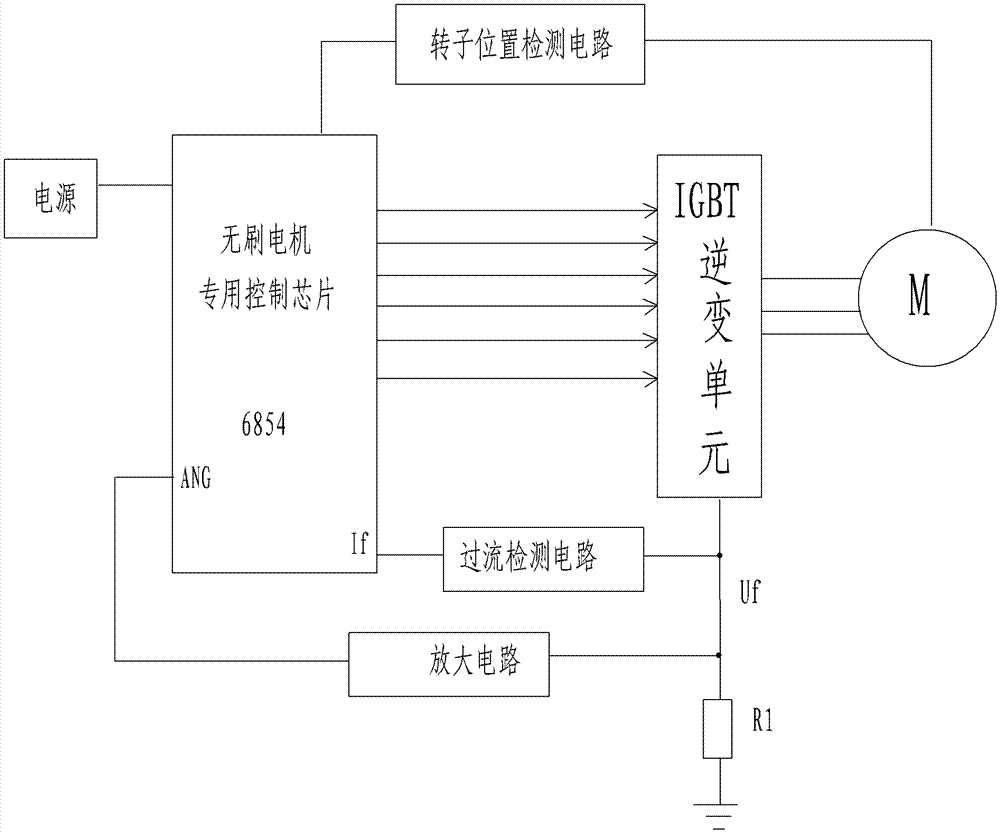

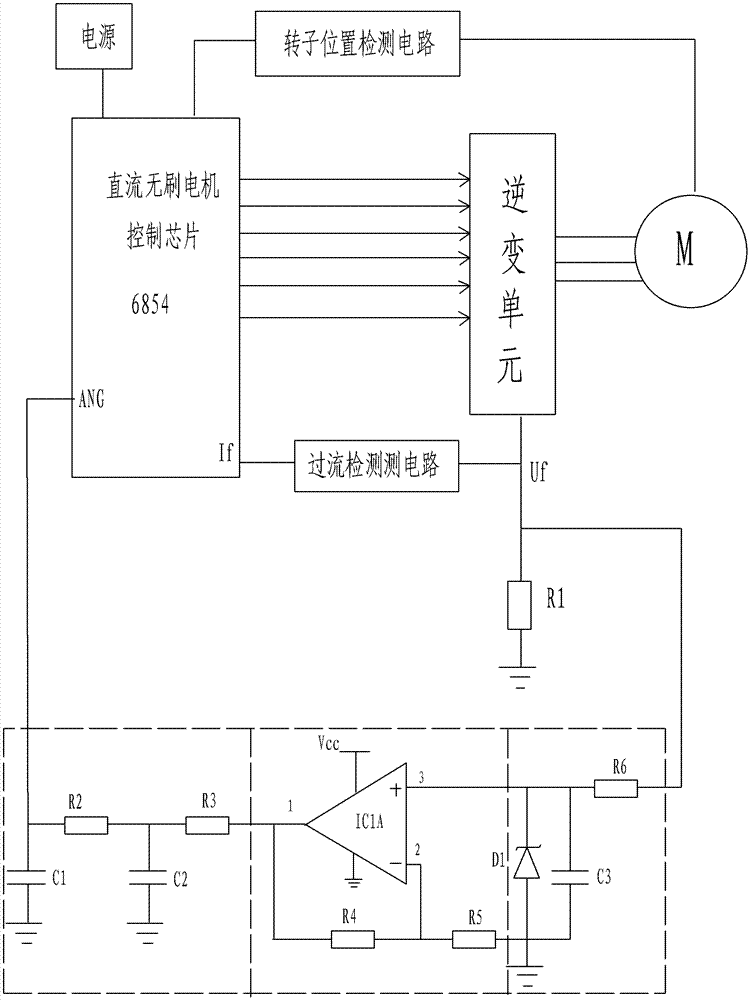

[0019] Such as figure 2 , image 3 As shown, a brushless DC motor controller with automatic phase advance angle adjustment of the present invention includes a dedicated control chip for brushless motors, an IGBT inverter unit, a rotor position detection circuit, an overcurrent detection circuit and a power supply, and the overcurrent detection The circuit detects the bus current signal and converts it into a voltage signal Uf, which is sent to the overcurrent input pin If for the special control chip of the brushless motor. The rotor position detection circuit inputs the position signal of the rotor to the special control chip of the brushless motor, and the special control The chip outputs signals to the IGBT inverter unit, the output end of the IGBT inverter unit is connected to the motor winding, the voltage signal Uf out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com