construction machinery

A technology of construction machinery and mechanical connection, applied in mechanical equipment, motor, engine control and other directions, can solve problems such as poor fuel consumption efficiency, and achieve the effect of high-efficiency charging and discharging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

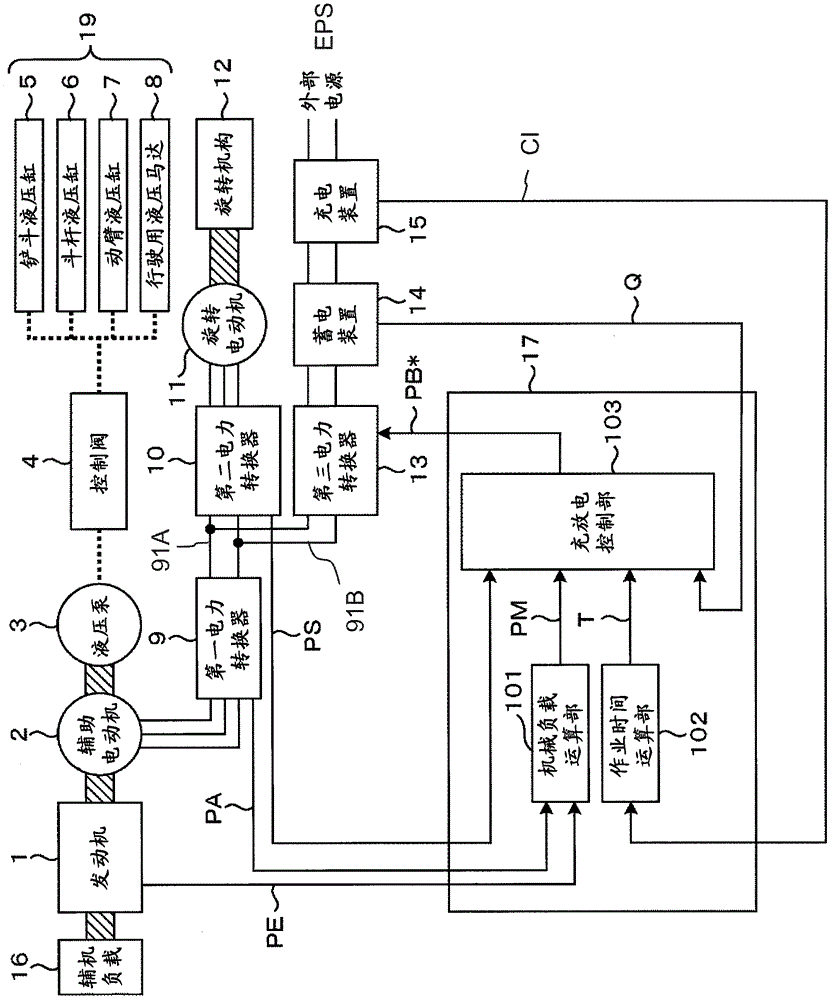

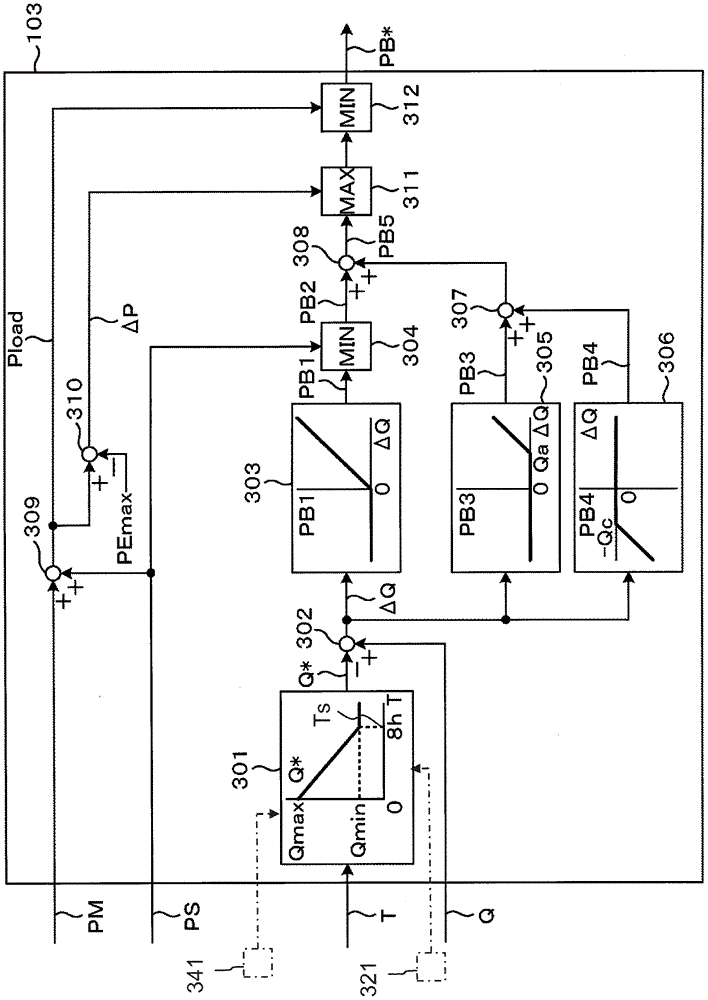

[0037] use Figure 1 to Figure 6 and Figure 9 A first embodiment of the present invention will be described. In addition, in the following description, the machine efficiency is not considered for the sake of easy understanding, but by controlling the machine efficiency in consideration, more accurate control can be performed.

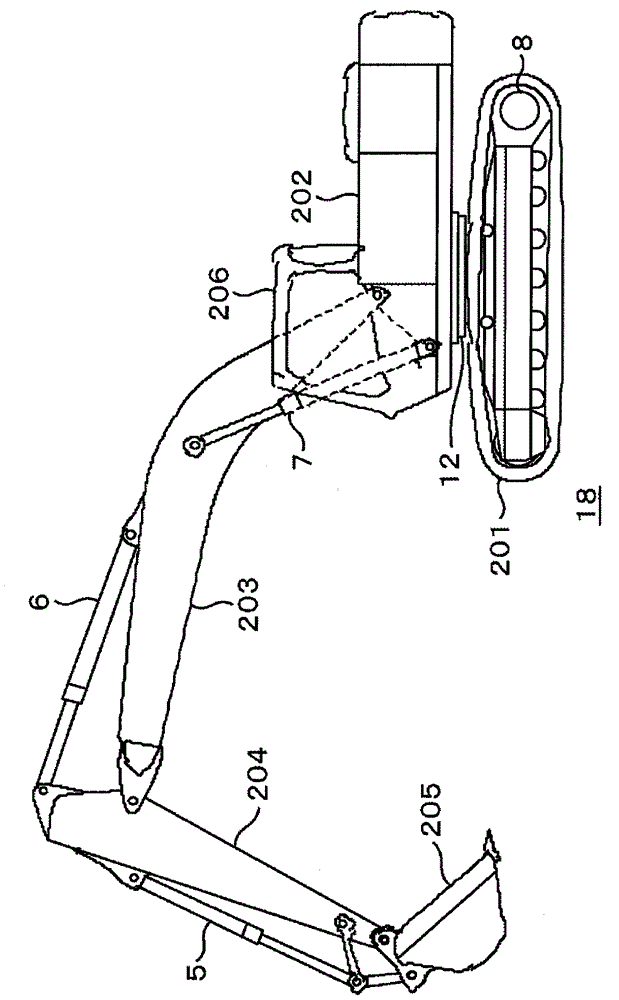

[0038] figure 1 It is a figure which shows the structure of the hydraulic excavator (representative example of a construction machine) to which this embodiment is applied. figure 1 Among them, the hydraulic excavator 18 has a traveling body 201 and a rotating body 202 .

[0039] The traveling body 201 has a function of driving the construction machine by the traveling hydraulic motor 8 .

[0040] The rotating body 202 is rotated relative to the running body 201 by the rotating mechanism 12, and has a boom 203, an arm 204, and a bucket for excavating on the other side (for example, the right side facing forward) of the front portion of the rotating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com